Easy-Arc Standard Welding Cells

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Easy-Arc Standard Welding Cells

Enclosed Robot Welding Systems

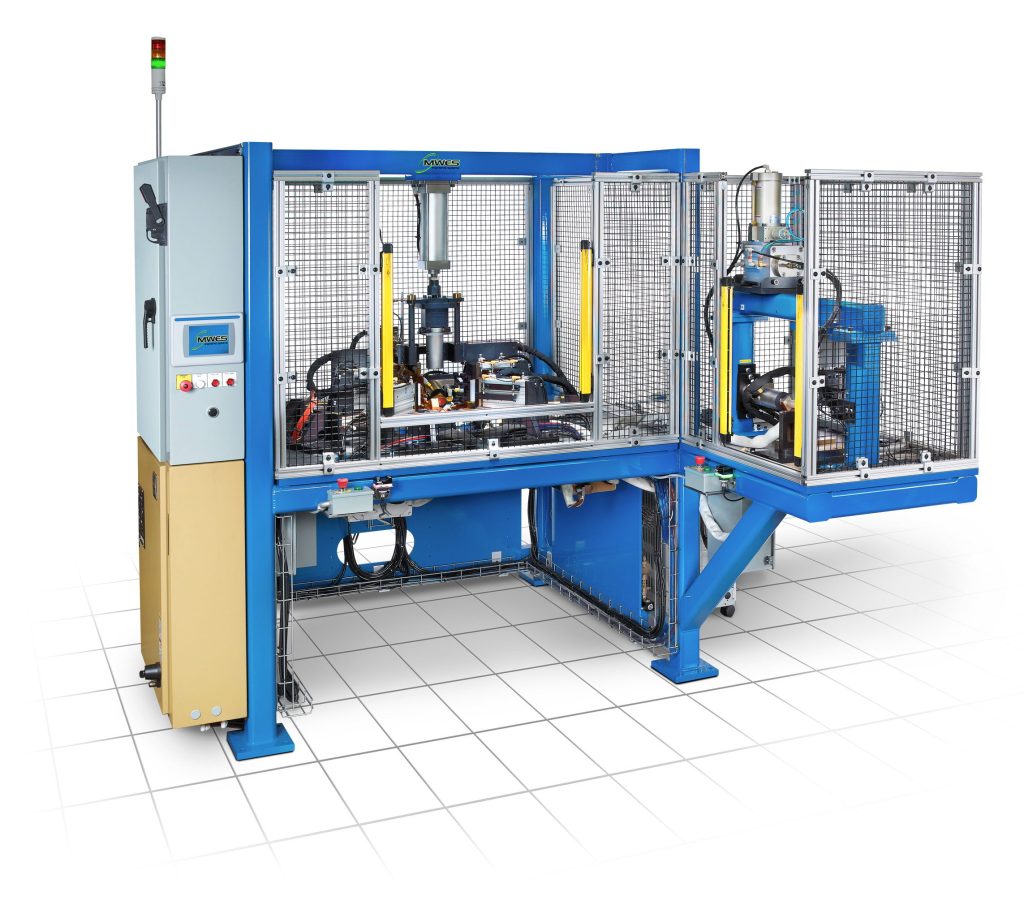

MWES Easy-Arc Standard Welding Cells

Midwest Engineered Systems has decades of experience designing and constructing robotic welding systems. Our standard automated welding cells can accommodate both simple and complex welding applications. Our Certified Welding Inspectors (CWI) and Certified Robotic Arc Welding Technicians (CRAW-T) can work with our customers to help implement this standard welding automation.

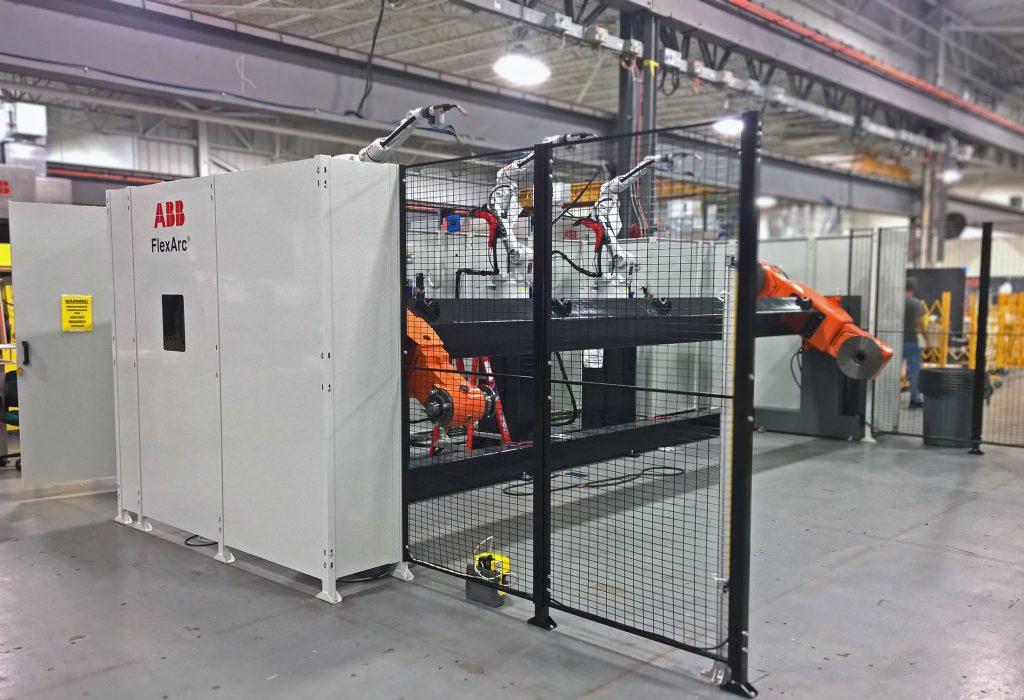

Our goal for our standard robotic welding cells is to provide the best options in terms of high quality, reliable performance, and price point considerations. These complete and turnkey production welding systems are built to accommodate a variety of industries with manufacturing components and to do so in a superior manner to manual welding processes. These are pre-engineered, robotic welding systems that can be employed in your industrial setting to ensure consistent and reliable welding production output.

Flexible Modular Packages

Our complete robot-operated welding systems are available in several flexible modular packages to suit your needs. With adaptive software and high-speed drives, all of these modular packages are highly productive and support rapid changeovers. These capabilities all mean less time spent on training and engaging in dangerous procedures with tremendous room for human error.

With these modular packages, everything is ready to use and safe. Indeed, they all feature all of the necessary safety features, and they come with roll door and light curtain options to suit the demands of your welding operation.

Rely On MWES For Your Standard Welding Cells

For high-quality and affordable welding solutions, turn to Midwest Engineered Systems. Our standard welding cells are designed with various applications and capacities in mind. We have built many robotic welding systems, guided by our years of welding experience and expertise. Our current robotic standard welding cells were designed by applying the knowledge we have gained about building and customizing systems. For example, we have noted some of the most frequently requested features from custom-built systems and applied those, where appropriate, to our new standard offerings.

To learn more about our options for standard welding cells and what features will work best for your industry, contact MWES today.

Building the future of manufacturing, together

World-class Automation