Robotic Picking & Packaging

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- Robotic Picking & Packaging

Transition Your Picking & Packing Process to Robotic Automation

Speed and consistency are key to successful consumer packaged goods product production. Both of these metrics have everything to do with how difficult it is to find and retain a quality workforce that can keep up with the increasing production speeds that automated food processing machines can achieve.

Automated picking and packaging systems are becoming more popular in various industries, such as food and beverage, pharmaceuticals and logistics. These systems perform tasks such as picking items from shelves, sorting them into boxes, labeling them, and sealing them for delivery. They can also handle a wide range of products and orders, from small to large, simple to complex and standard to customized. These systems offer many benefits for businesses and customers alike.

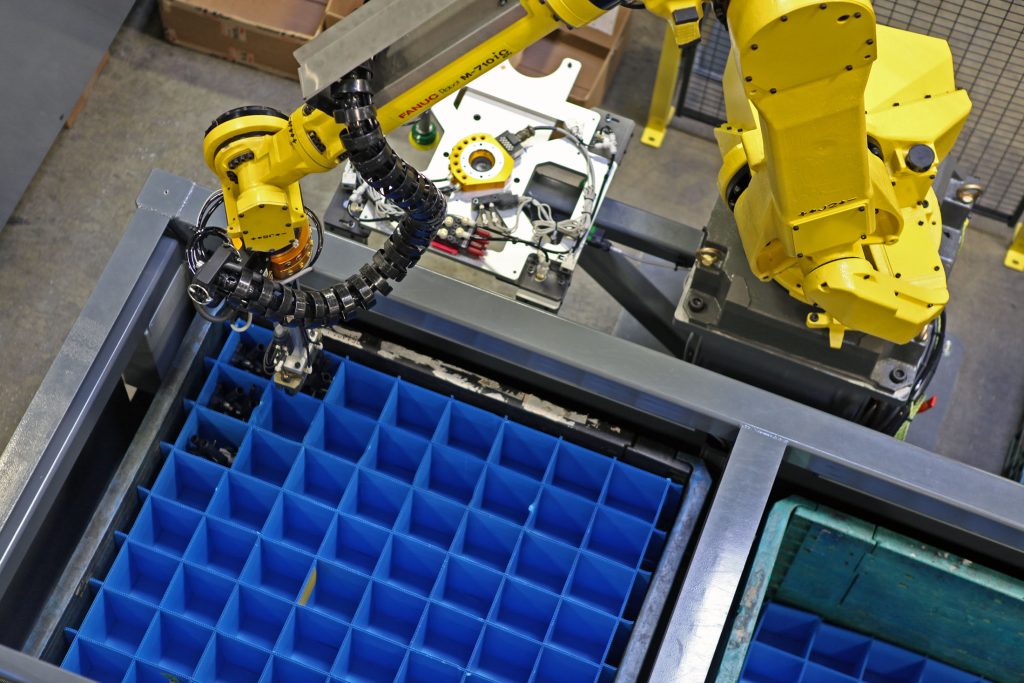

Utilize Dynamic Vision Picking with Robotics for speed & Efficiency

Until now, robotic packaging systems were not the best choice for filling these needs due to bagged food products’ inconsistent shapes and orientations. That all changes with Midwest Engineered System’s blend of best-in-class robotic dynamic vision systems and high-speed, pick-place robotics. Now, these systems can almost flawlessly pack between 120-160 packages per minute.

Dynamic vision picking can be implemented using conveyor belts and vision systems. Parts pass through scanners and are presented to the robot without human interference. 3D vision systems locate the parts on a moving surface and direct the robot for proper gripping and positioning.

Dynamic vision picking can bring about the following production line improvements:

- Improved Ergonomics

- Reduce costly loss time due to injury or illness

- Less than a 2-year return on investment (ROI)

- Remove workers from the dangerous work environment

- Increase work productivity and quality

If your manual workforce is lagging in throughput, then contact us today. MWES can analyze your existing process and provide a robotic solution that can best suit your needs.

Building the future of manufacturing, together

World-class Automation