Fixed Automation Systems

- Home

- Industrial Automation Capabilities

- Assembly Automation

- Fixed Automation Systems

Achieve High Efficiency by Automating Fixed Processes

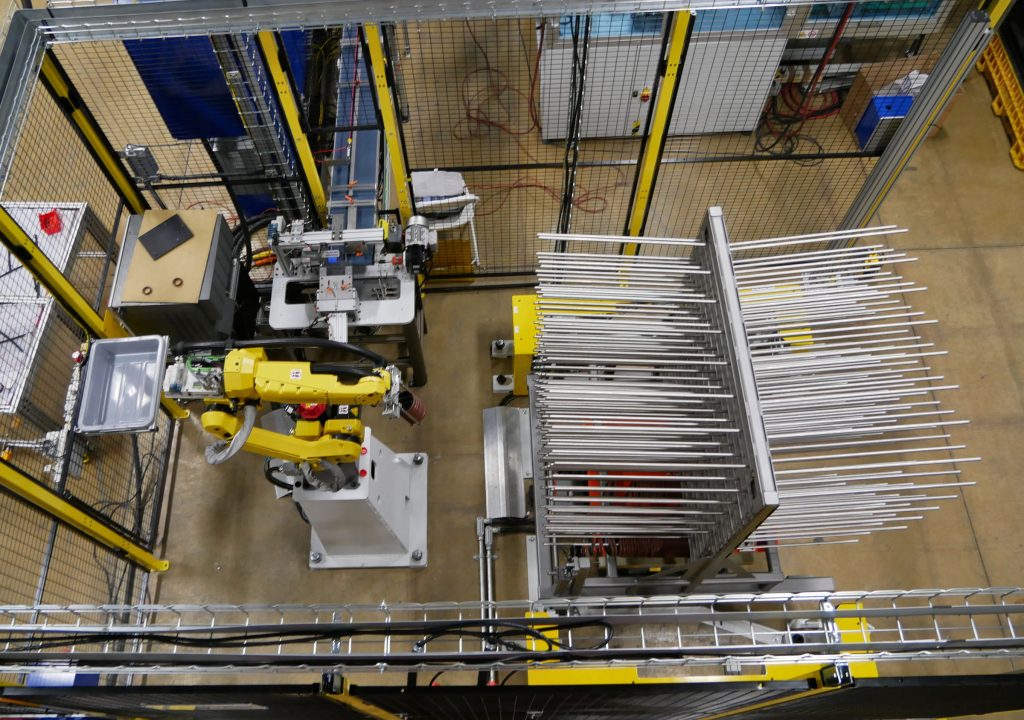

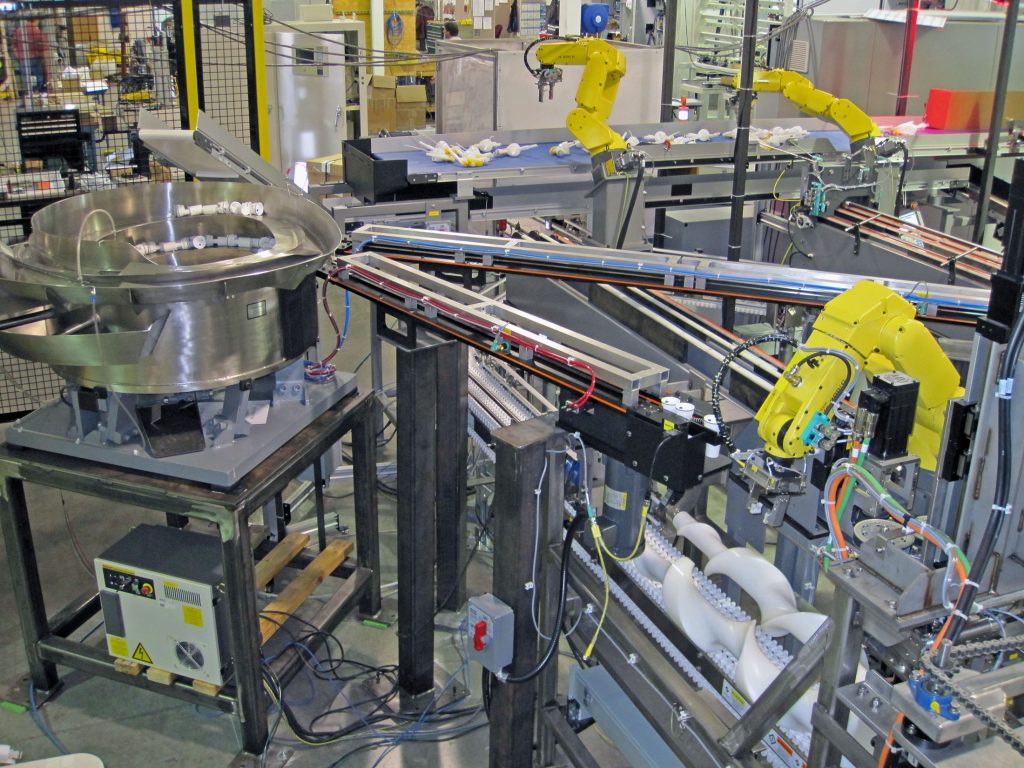

Fixed automation systems, also known as hard automation, are typically used for production systems with exclusively allocated equipment and high-production needs. Midwest Engineered Systems has decades of experience developing, installing and servicing specialized production automation systems for a variety of industries. Through this experience, MWES knows what it takes to build purpose-built automation systems for the highest quality product at the best possible throughputs.

MWES knows the equipment in a fixed automation system is manufactured and designed to perform only one set of operations on one part with high levels of efficiency. These discrete mass production systems work with purpose-built machine equipment that carries out repetitive, fixed processes to reach high-volume production goals.

In fixed automation, the sequences and types of operations allowed by the configuration of the equipment are finite and preset. Wiring, cams, gears and other hardware deliver the programmed instructions that these automation machines follow in the production process. These systems tend to manufacture the same product style, and they are designed in a way that makes changing product styles difficult.

Applications where fixed automation systems work best:

- Automated assembly machines

- Chemical manufacturing processes

- Material handling conveyor systems

- Machining transfer lines

- Paint and coating automation processes

- Web handling and converting systems

Despite its initially high investment costs, this type of automation system is well-suited for high-volume production processes where products tend not to change much over time. This allows for the higher cost of fixed automation system design and construction to be stretched where systems can be thoroughly amortized long before production ceases.

Contact Midwest Engineered Systems to learn how we can analyze your current production systems and develop a fixed automation system that increases productivity and efficiency!

Building the future of manufacturing, together

World-class Automation