Autonomous Mobile Robots (AMR’s)

- Home

- Industrial Automation Capabilities

- Material Handling Automation Systems

- Autonomous Mobile Robots (AMR’s)

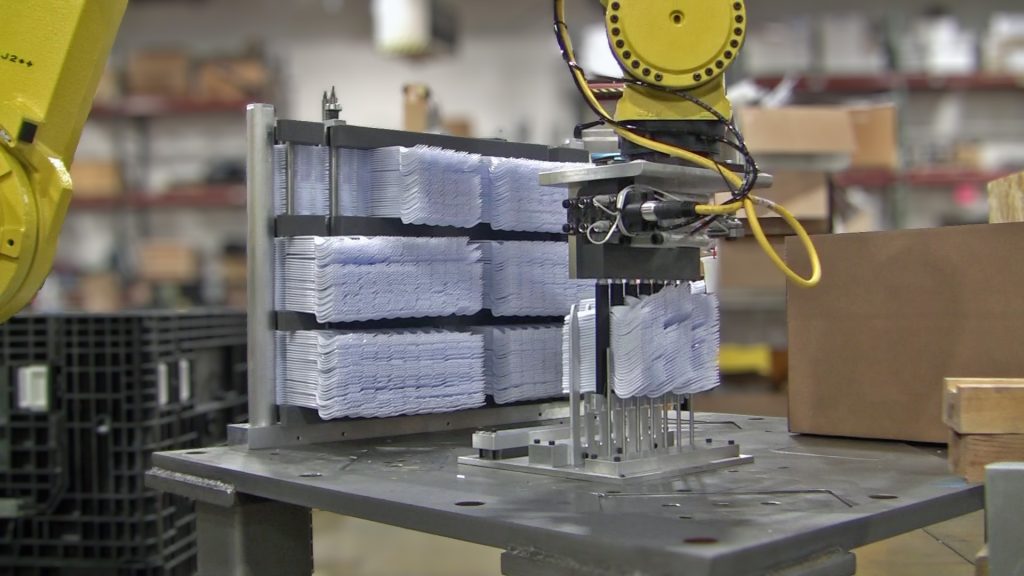

The Next Generation of Factory Automation

Autonomous Mobile Robots (AMRs) are self-contained robotic systems equipped with sensors, cameras and advanced software systems that allow them to navigate and perform tasks completely autonomously without the need for physical infrastructure. They have sophisticated navigation capabilities and can avoid collisions with people, equipment and other obstacles. They can also dynamically adapt to new layouts, reconfigurations and changing operational demands on the fly.

Like Automated Guided Vehicles (AGVs), AMRs can perform tasks that are repetitive, tedious or dangerous, typically performing material handling and transportation operations. Unlike AGVs, AMRs do not require the use of fixed paths using infrastructure like wires, magnetic tapes or sensors. AMRs can work alongside human workers and each other, forming networks of automation systems that work in harmony.

Like Automated Guided Vehicles (AGVs), AMRs can perform tasks that are repetitive, tedious or dangerous, typically performing material handling and transportation operations. Unlike AGVs, AMRs do not require the use of fixed paths using infrastructure like wires, magnetic tapes or sensors. AMRs can work alongside human workers and each other, forming networks of automation systems that work in harmony.

The use of AMRs throughout all industries is increasing at a rapid pace. With current labor shortages, AMRs are used heavily in the logistics, healthcare and manufacturing industries, and are beginning to expand into other industries as industries begin reshoring jobs.

AMRs are not only a technological innovation, but also a social and economic opportunity. They have the potential to improve our lives, our work and our society in many ways. MWES is at the forefront of robotic automation and automation integration. Contact us today if Autonomous Mobile Robots are in the future for your logistics operation.

Benefits to using Autonomous Mobile Robots

Building the future of manufacturing, together

World-class Automation