Assembly Automation

- Home

- Industrial Automation Capabilities

- Assembly Automation

Bringing process together with

Automated Assembly Solutions

We have the automation solutions to improve your assembly throughput

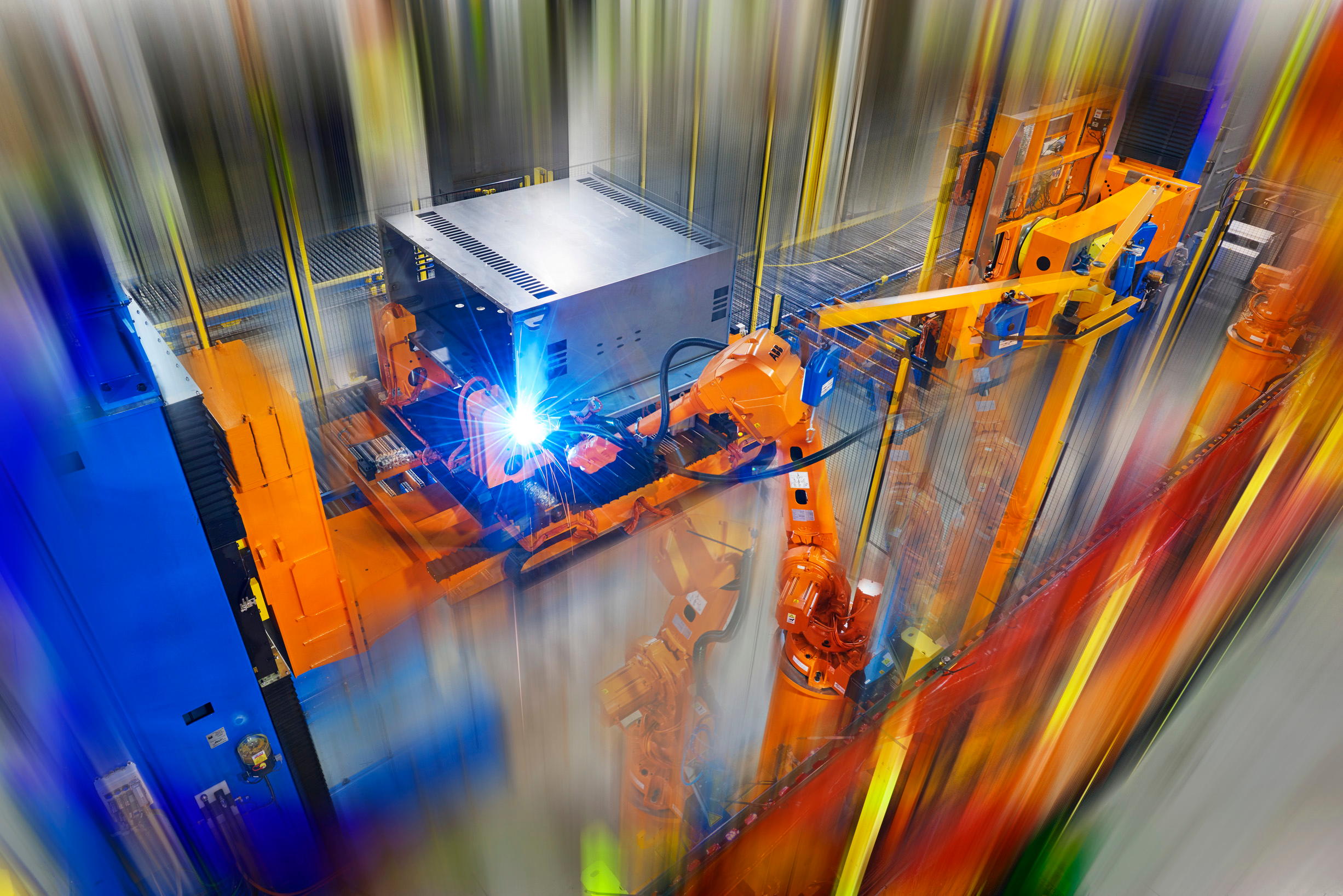

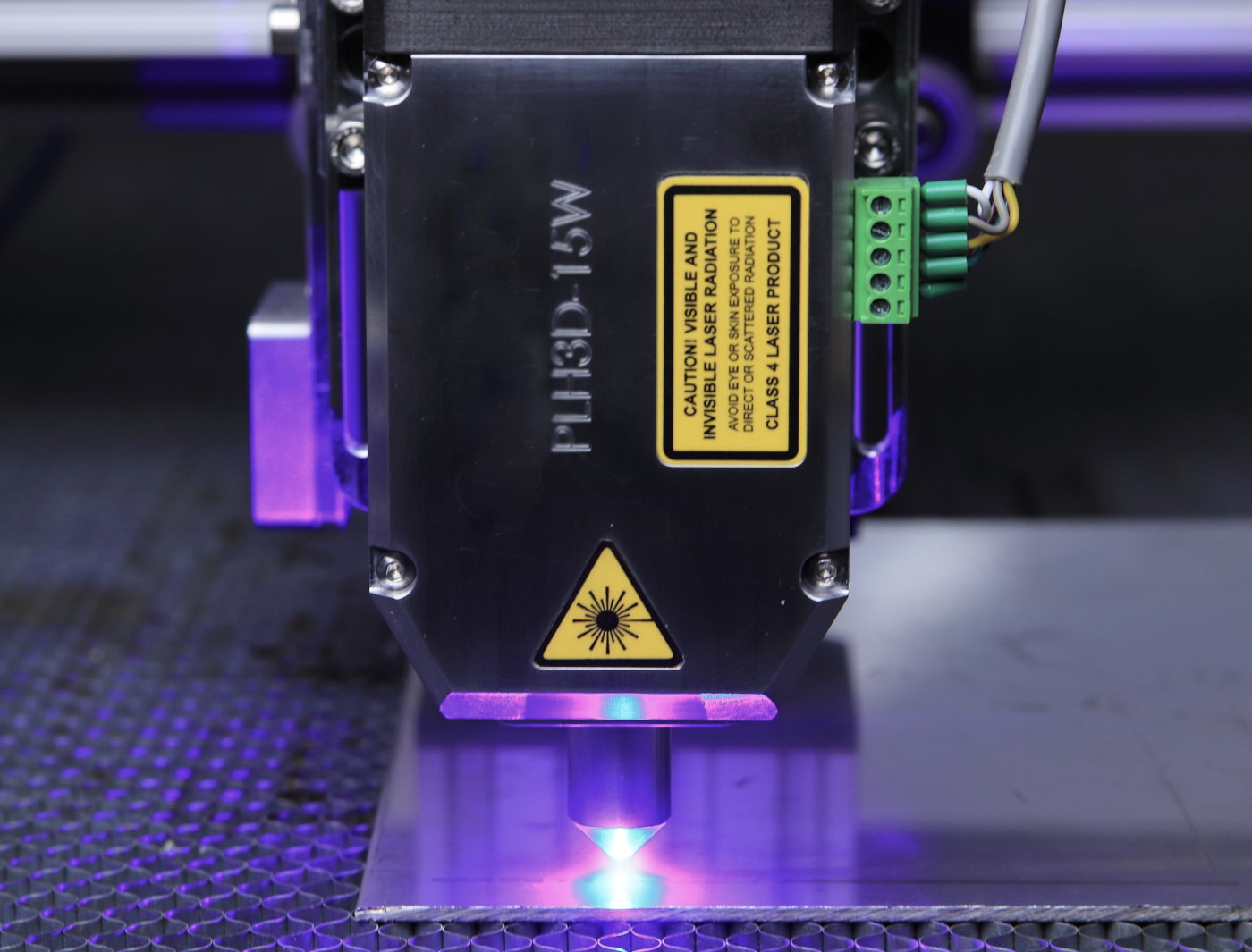

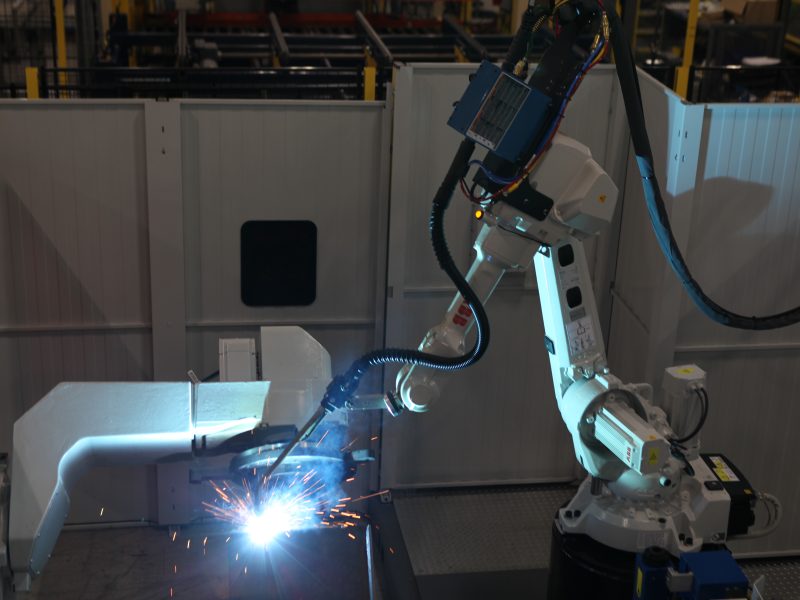

Industrial-scale automation in the 21st century is rapidly changing. With the current labor shortages along with rising labor costs, switching to robotic assembly automation has become a crucial next step for a lot of businesses. Midwest Engineered Systems has spent decades integrating automation products into existing production lines for businesses large and small. These automation solutions have provided our customers with increased production throughput, improved reliability and a great return on investment.

As a multi-vendor, multi-industry robotic factory automation integrator, Midwest Engineered Systems designs, builds, installs and services automated robotic assembly lines optimized for fast and efficient throughput. With decades of experience building production systems for a variety of sectors, MWES has built lines from electronic products to some of the largest industrial assemblies and everything in between. This diversity of clientele allows us to bring innovative solutions that get results for our customers.

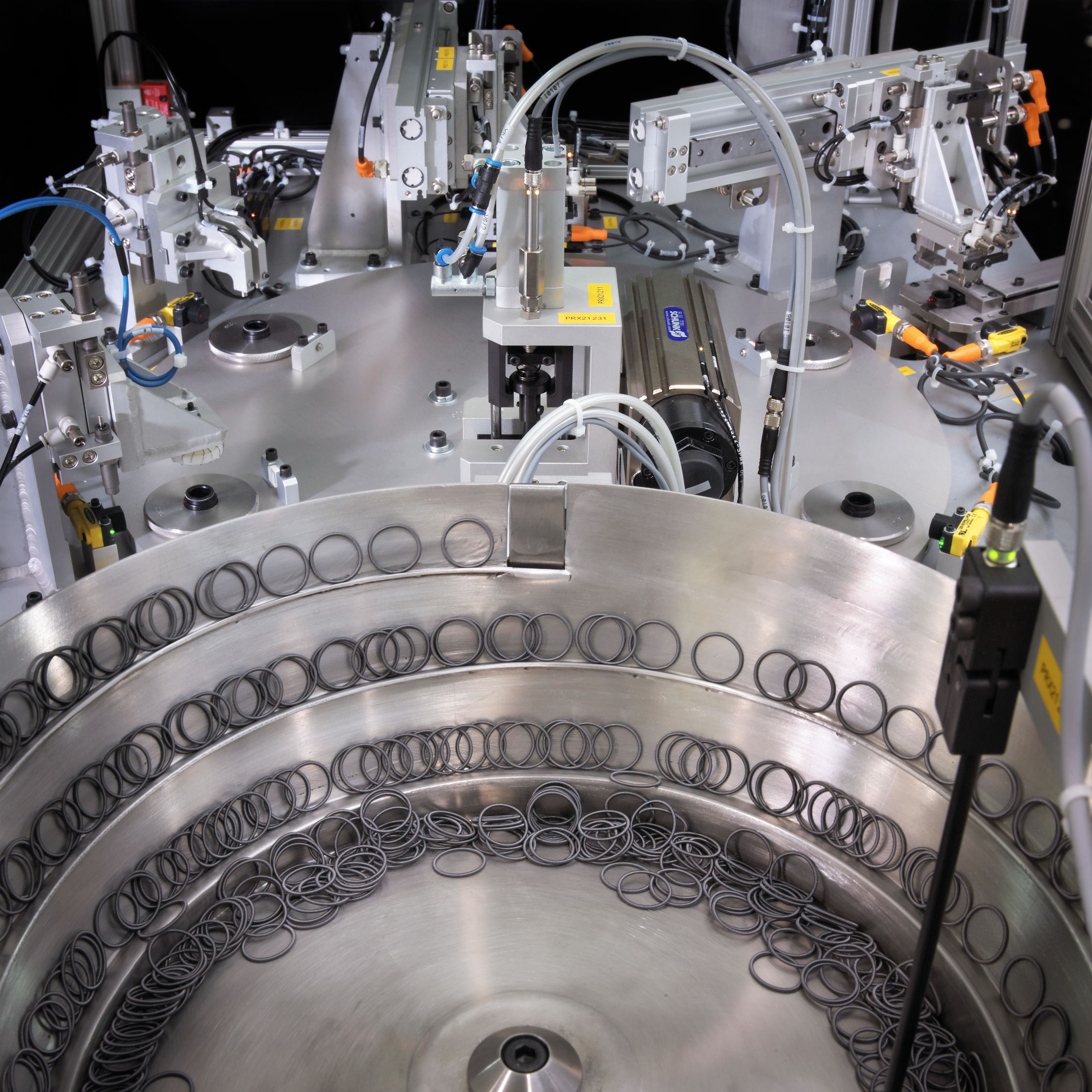

We partner with our customers to create custom assembly lines engineered for their specific manufacturing needs. While we certainly produce highly automated robotic assembly systems that can approach lights-out manufacturing, MWES is skilled at developing and streamlining manual assembly lines, as well. We’ve also built successful systems that integrate robotic aspects with manual processes – all dependent on our customer’s needs and the production goals to be attained.

MWES specializes in developing assembly systems to bring new products to market. Not only can we design clean sheet production systems, but we also have the experience and knowledge to be an advisor to our customers in engineering their products for manufacturability. And when it comes to an unavoidable new automation process, our proof of principle testing program helps reduce risk exposure by proving the feasibility of automation operations, without investing in an entire assembly system to find out when it comes time to build an assembly system, Midwest Engineered Systems makes sure the process and the system are as easy to operate and manage as possible. We design systems for ease of use, ease of monitoring and ease of maintenance. All of our systems include the latest in user-friendly features, such as graphic touchscreen interfaces, maintenance diagnostics, quality reporting, management control reporting, and many others.

Automation has become a pillar in today’s production environments. With the physical demands required of material handling work and the lack of highly skilled labor to perform challenging work such as welding operations, many businesses are turning to automation technology to grow their operation. From palletizing to case packing to machine tending, MWES has the experience and knowledge to provide integration of a wide range of complicated automated solutions.

Use Cases for Robotic Assembly Automation

Building the future of manufacturing, together

The Areas where we can Help