Robotic Automation Systems

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

Bringing process together with

Robotics and Robotic Automation Systems

Robots are the future of manufacturing

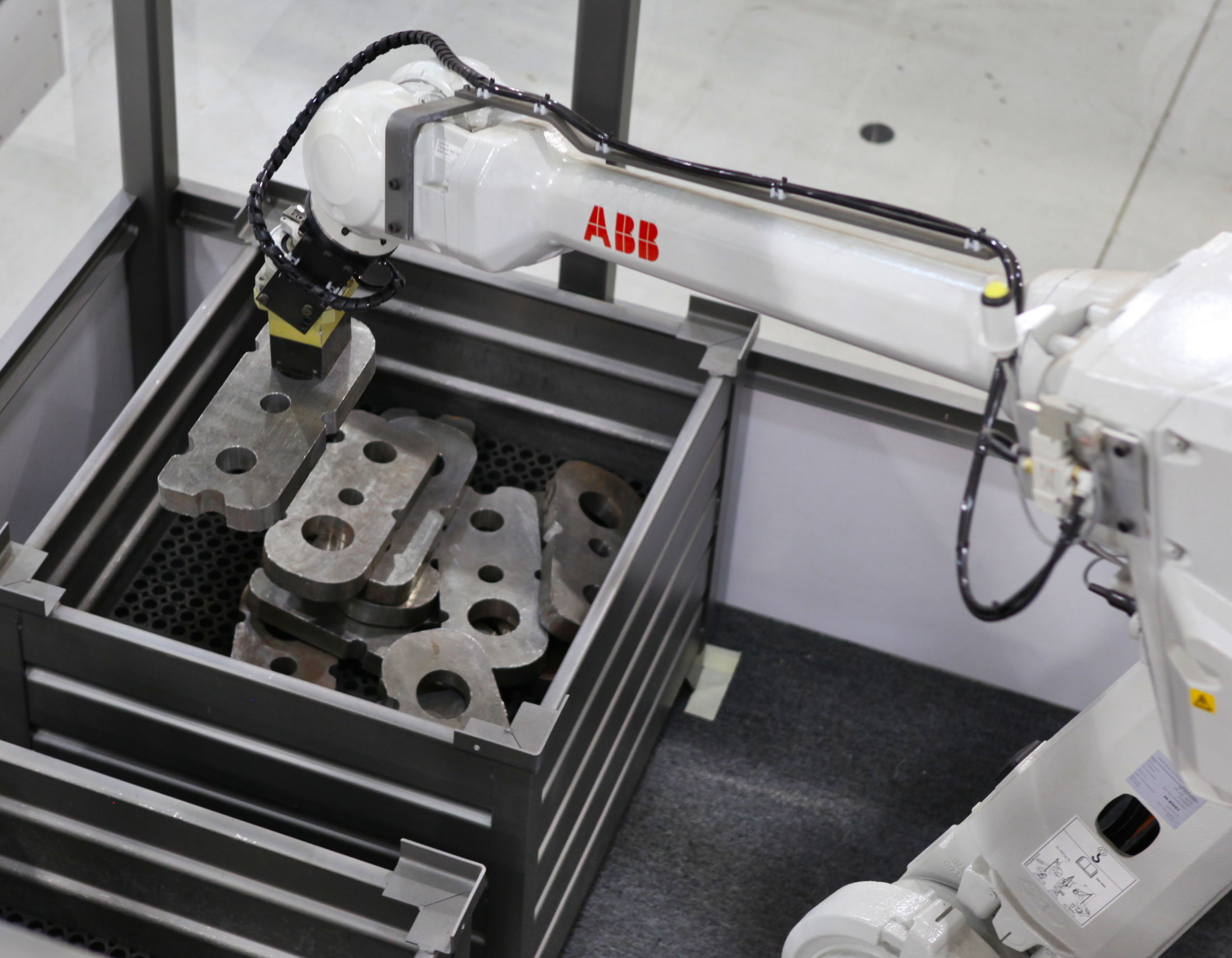

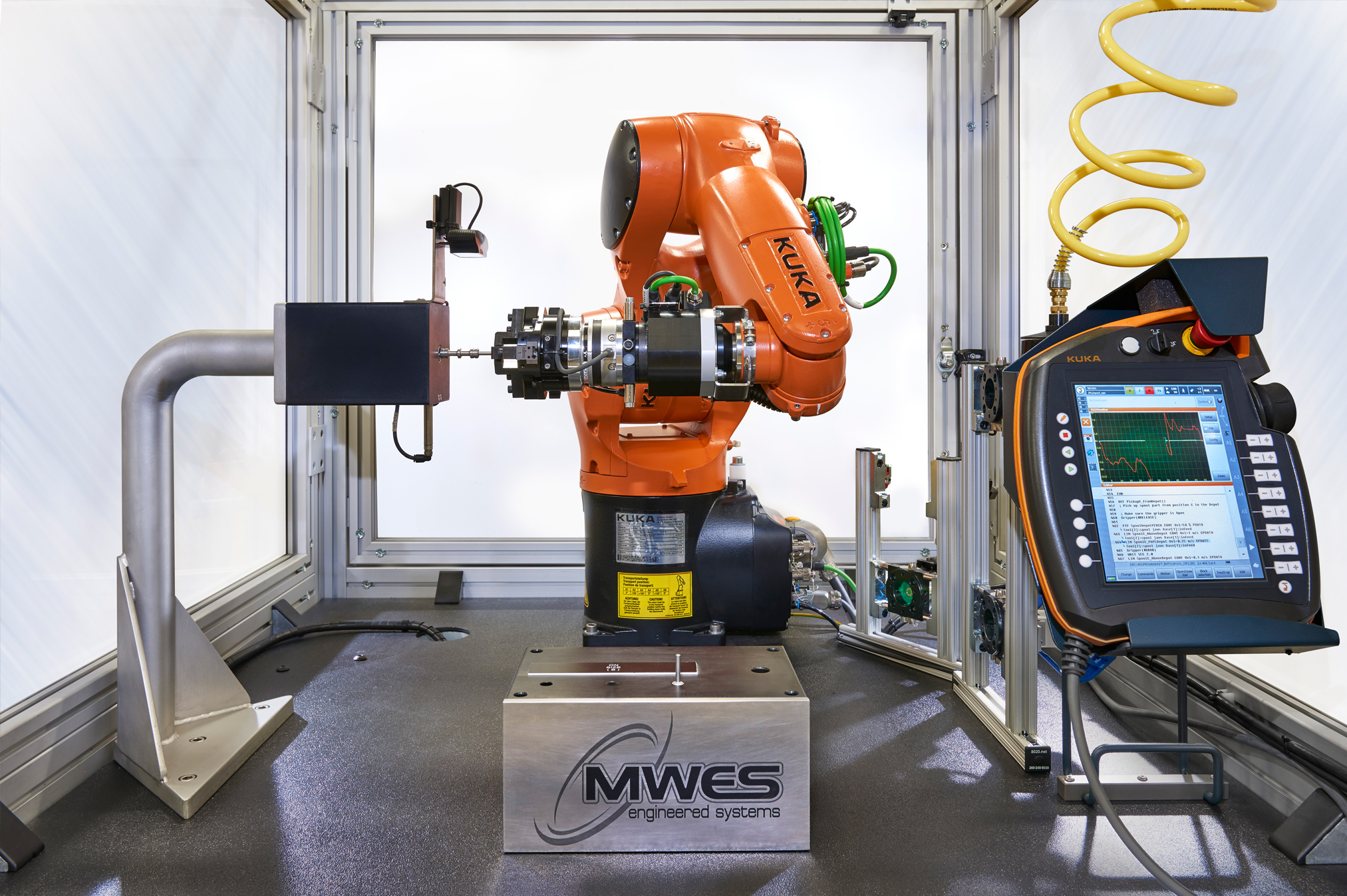

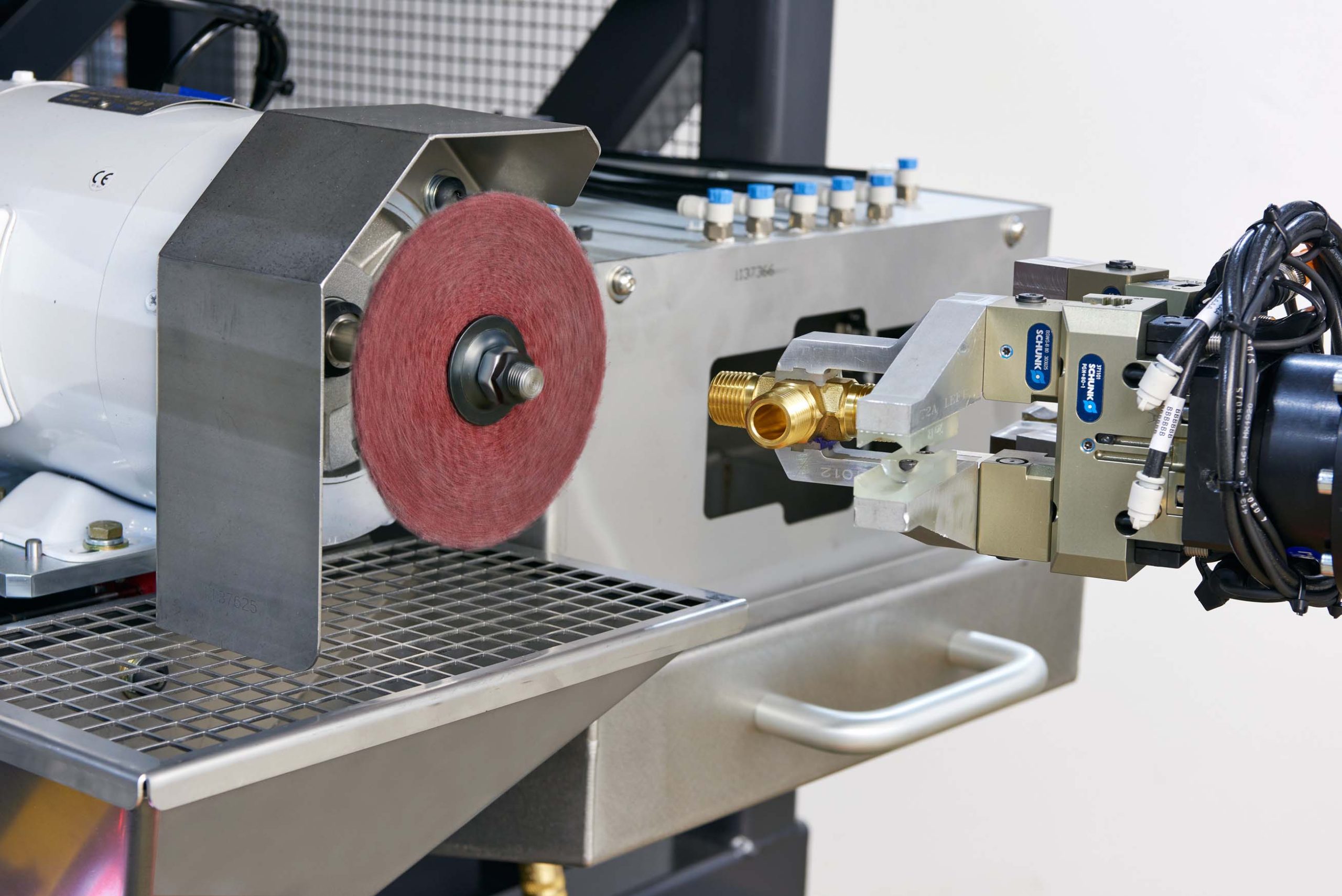

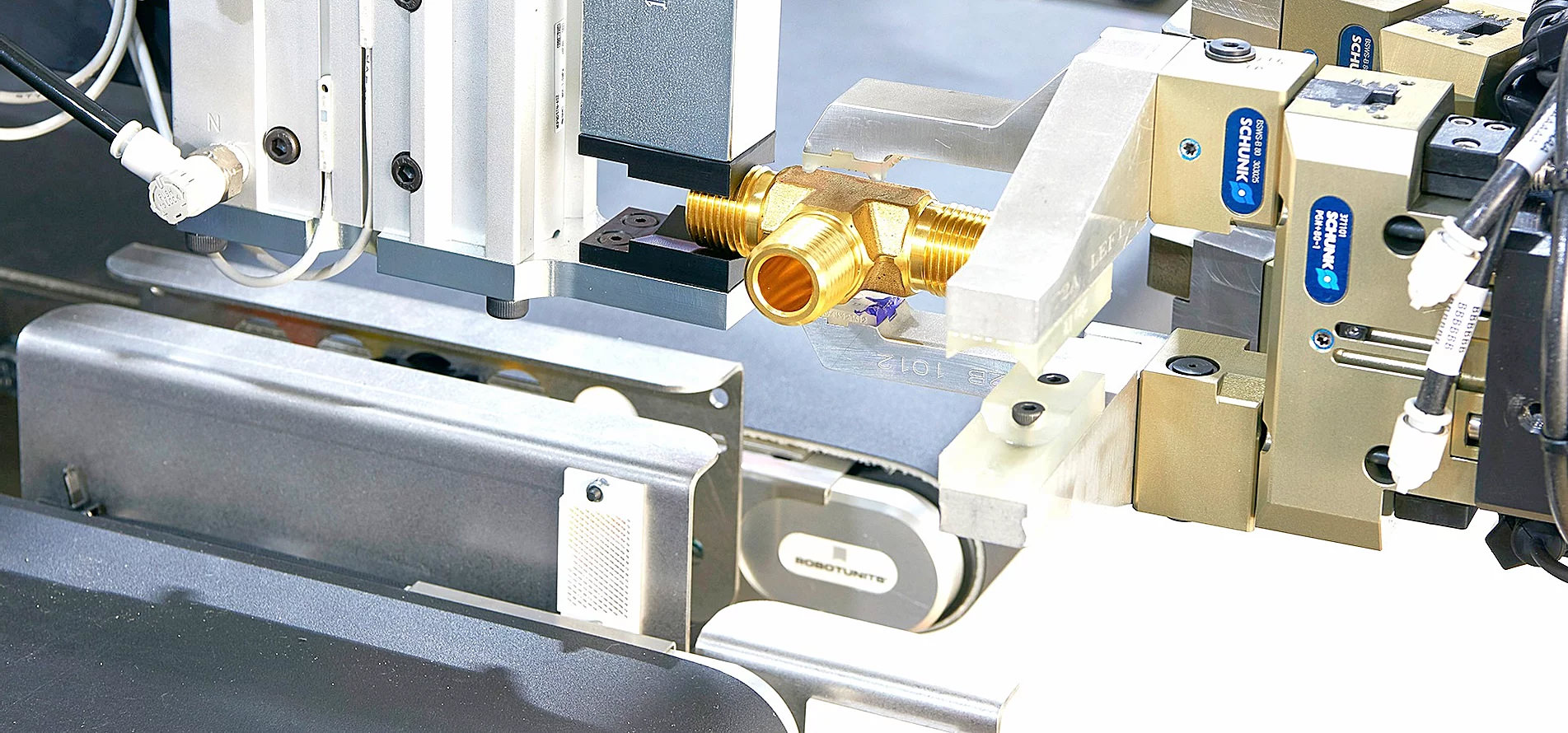

From small, stand-alone systems to large integrated processes, Midwest Engineered Systems custom designs each robotic integrated system for your specialized operational needs. MWES has designed and installed hundreds of robotic-based systems, for startup companies to Fortune 500 corporations. Integrated robotic automation systems offer many benefits for productivity, quality and safety.

Robotic automation systems can perform tasks faster, more accurately and more consistently than human workers. This can result in higher output, lower defect rates and a substantial return on investment (ROI). Robots can also handle hazardous or repetitive tasks that may pose risks or challenges for human workers. This can improve worker safety and satisfaction, as well as reduce labor costs and turnover. Robotic automation systems can adapt to changing demands and conditions in the manufacturing industry. This can enhance flexibility and innovation, as well as respond to customer needs and preferences.

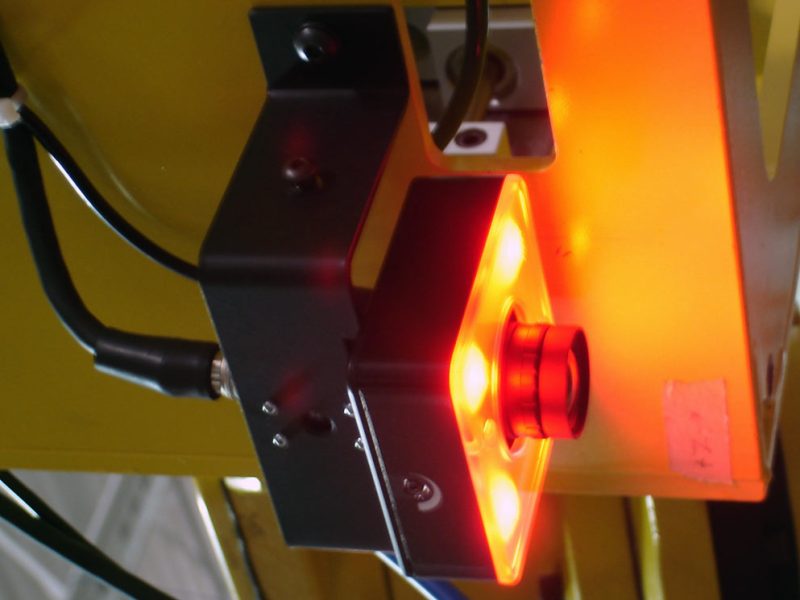

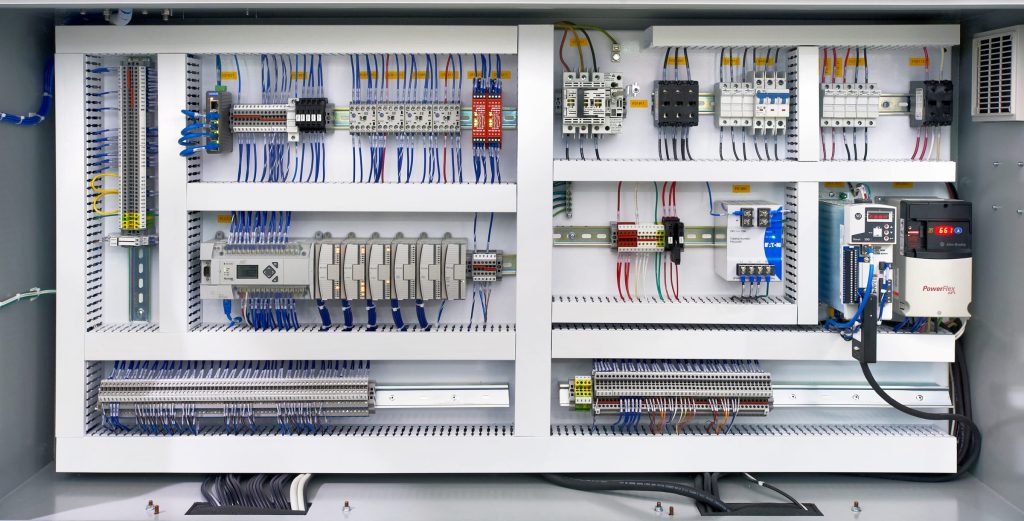

Our design and build solutions include customized robots, specialized End-of-Arm-Tools (EOAT), cable solutions, vision systems, safety enclosures, process monitoring, control systems and other equipment, to help you and your organization improve your manufacturing process.

MWES is a Certified Robotic Integrator

MWES has decades of experience working with these popular robotic manufacturers:

Building the future of manufacturing, together

The Areas where we can Help