Mining & Agricultural Vehicles

- Home

- Industries

- Mining & Agricultural Vehicles

Over 30 Years Helping

Make mining and agriculture safer and more efficient

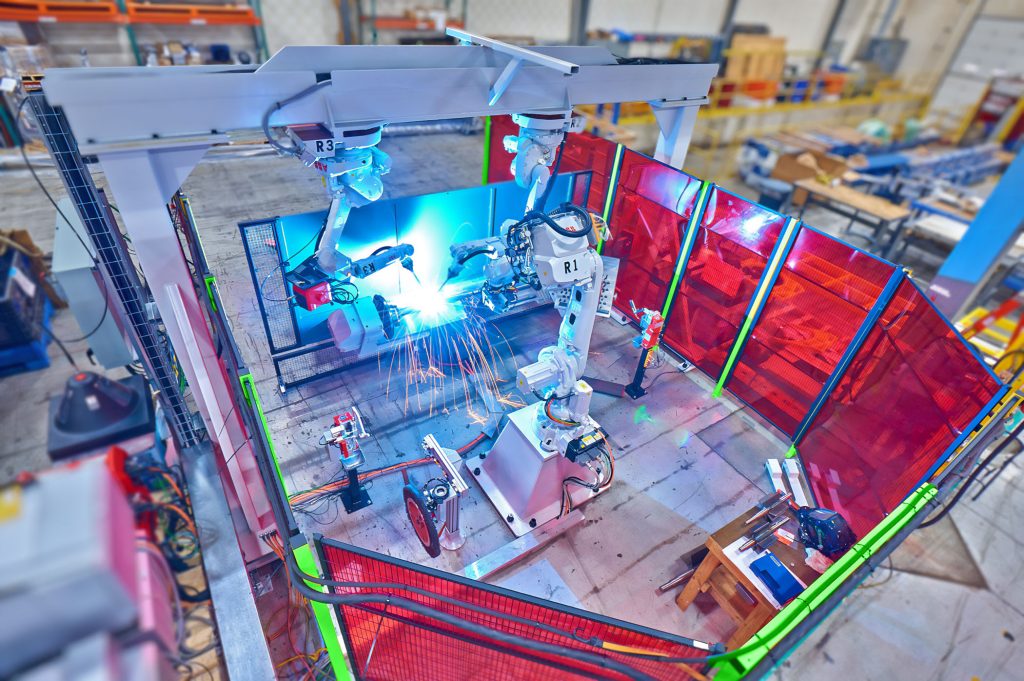

As the world’s population continues to grow, demand for mining and farming equipment is also continually on the rise and more businesses are turning to robotic automation to keep up with demand. Robotic automation can take the place of a dwindling workforce and bring about improved efficiency and productivity.

Manufacturing large industrial vehicles necessitates large robotic automation and manufacturing systems. Midwest Engineered Systems has experience developing and implementing large factory automation systems that can manufacture components efficiently and safely. We have designed systems to handle various operations performed on engine components, storage vessels, vehicle frames and more.

Automation Applications

mining & agricultural expertise

Engine & Transmission

Engine Component Assembly

Frame, Cab & Suspension

Consumable Wear Items

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing