Robotic Sanding

Enhance Your Industrial Sanding Operations with Robotics

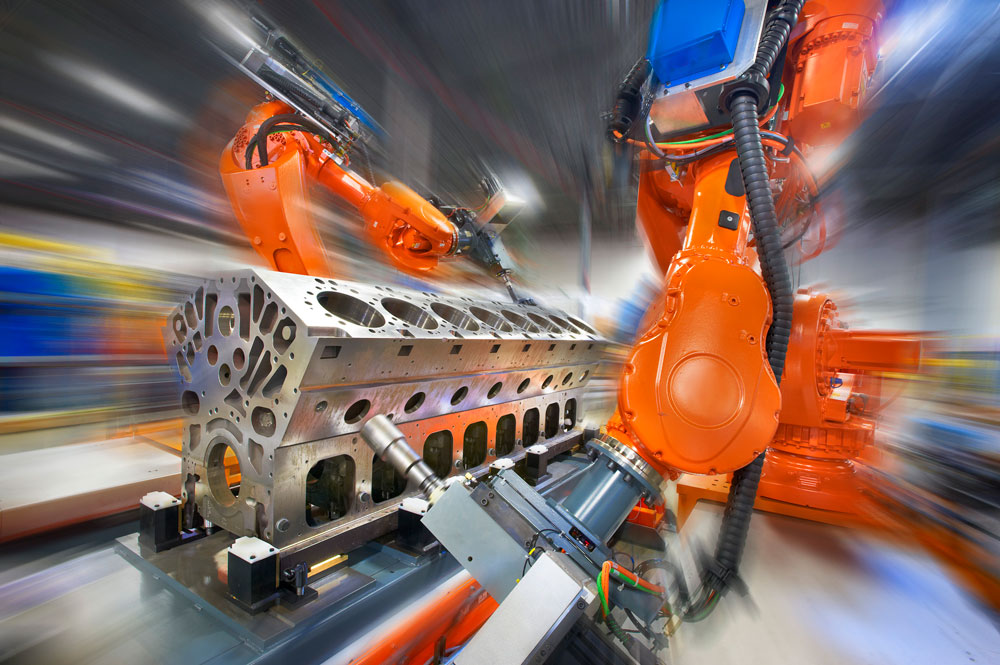

Part sanding is an incredibly common operation in many industries, such as woodworking, metal casting, steel framing and consumer goods manufacturing. Sanding operations can improve the quality, appearance and functionality of the products, but it can also be tedious and repetitive and also produce hazardous dust that can be harmful for manual labor.

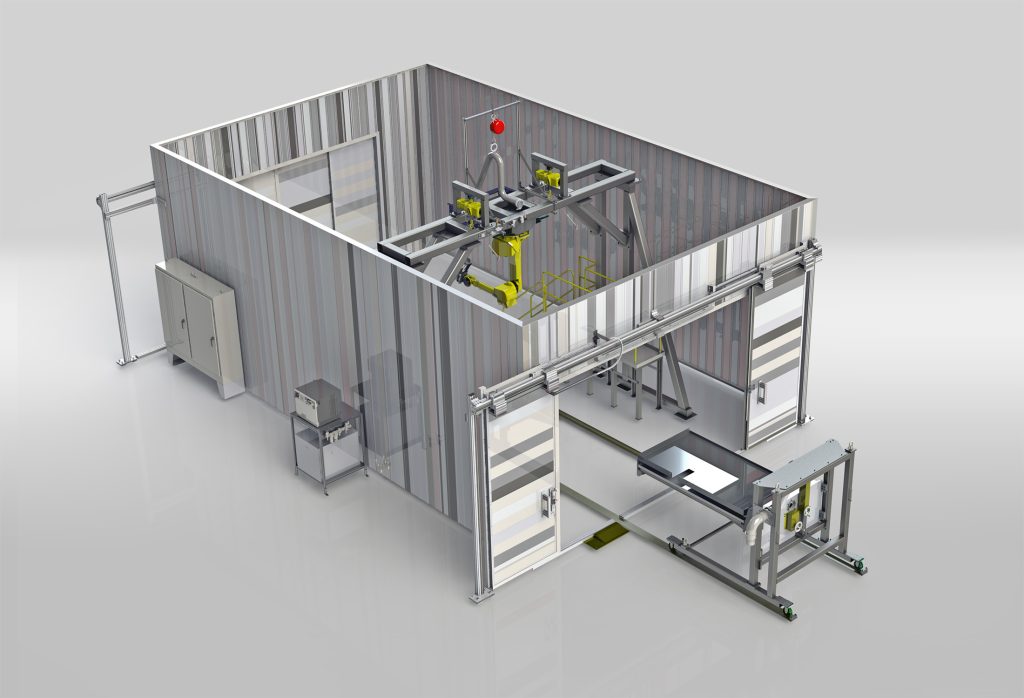

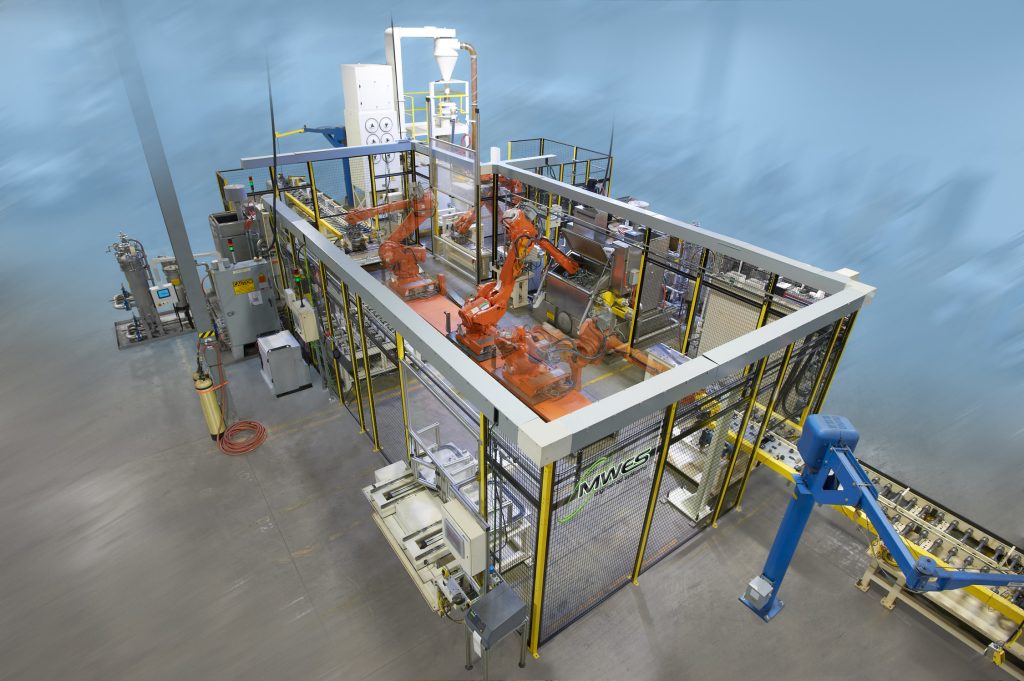

Robotic automation can improve industrial sanding operations by the use of a robot end-of-arm tool (EOAT) sander or simply tending an industrial sanding machine. By utilizing robots, sanding operations are provided with increased productivity since robots can work faster, longer, and more consistently than humans and they can handle complex shapes that may be difficult for manual sanding. Additionally, robots can achieve precise and uniform results as well as reduce the risk of part reworking and material waste and also adapt to different materials and surface conditions with sensors and feedback systems. Robotic automation can reduce repetitive motions and awkward postures of workers and the exposure to dust, noise and other hazards associated with sanding.

Industrial robotic sanding automation can improve productivity, quality, safety and overall sustainability as well as provide a return on investment (ROI) to any manufacturing operation that requires material removal. If your business is looking to upgrade a manual sanding operation to an automated robotic sanding operation, please contact us today.

Building the future of manufacturing, together

World-class Automation