Engineered for What’s Next

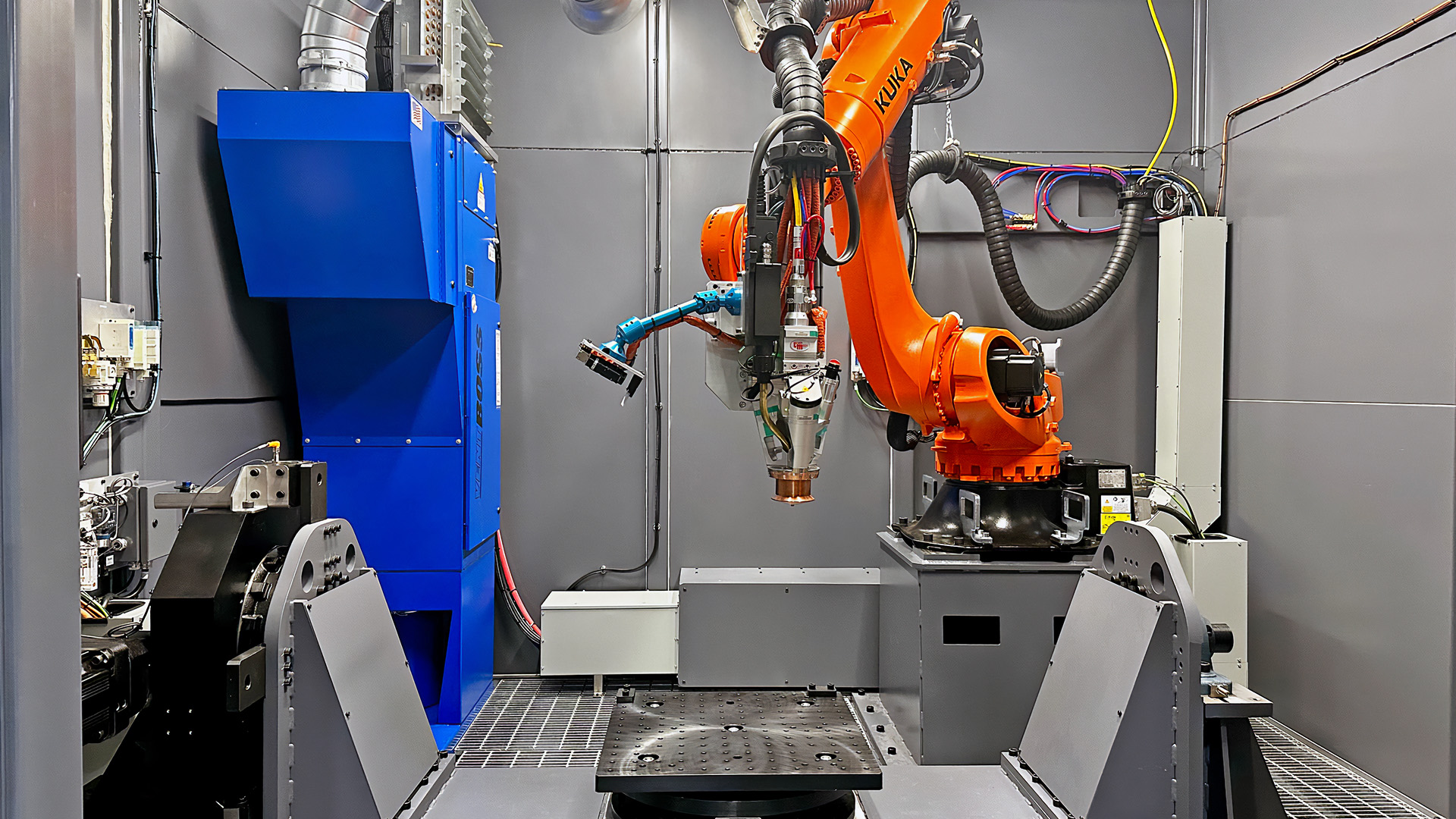

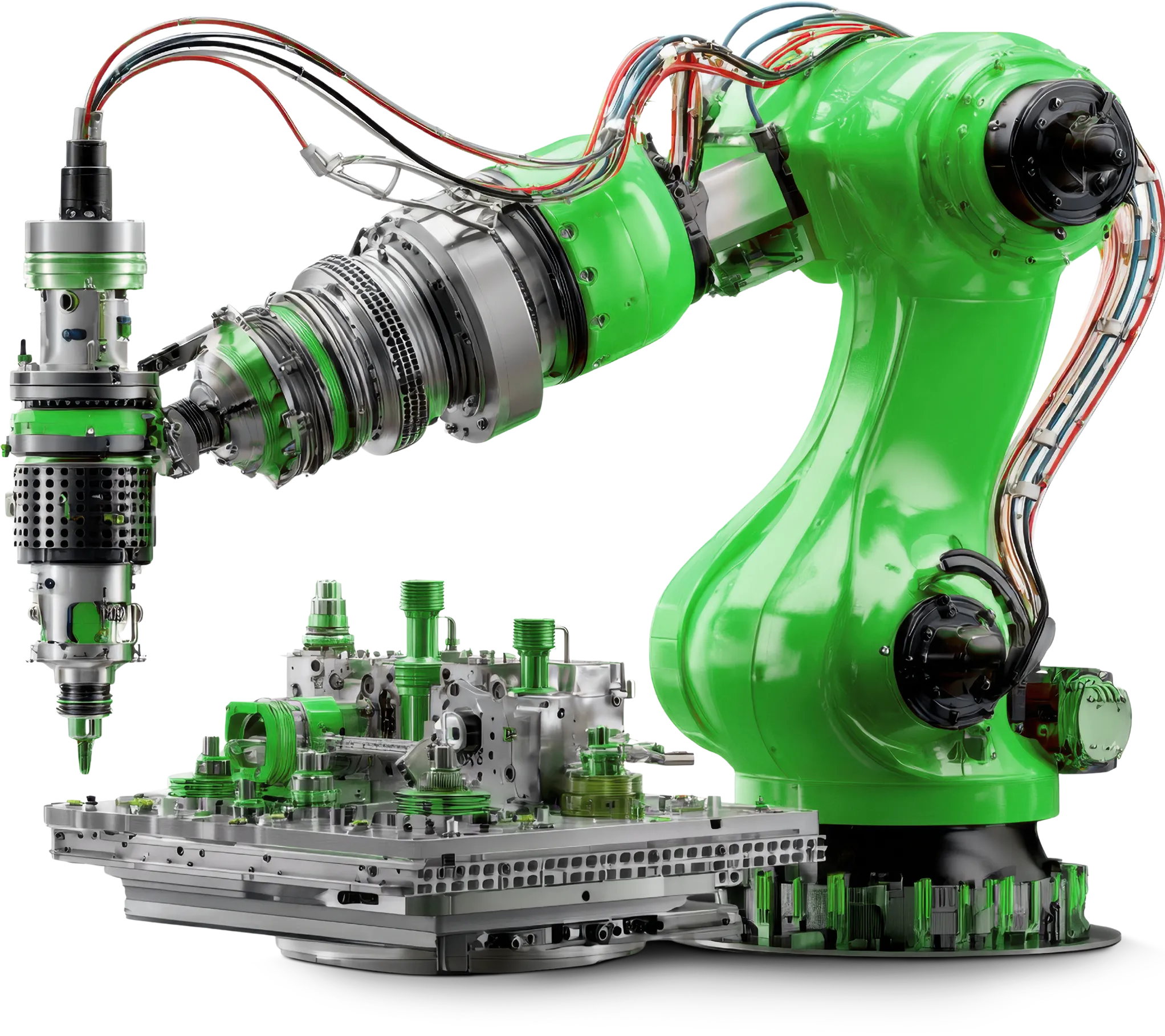

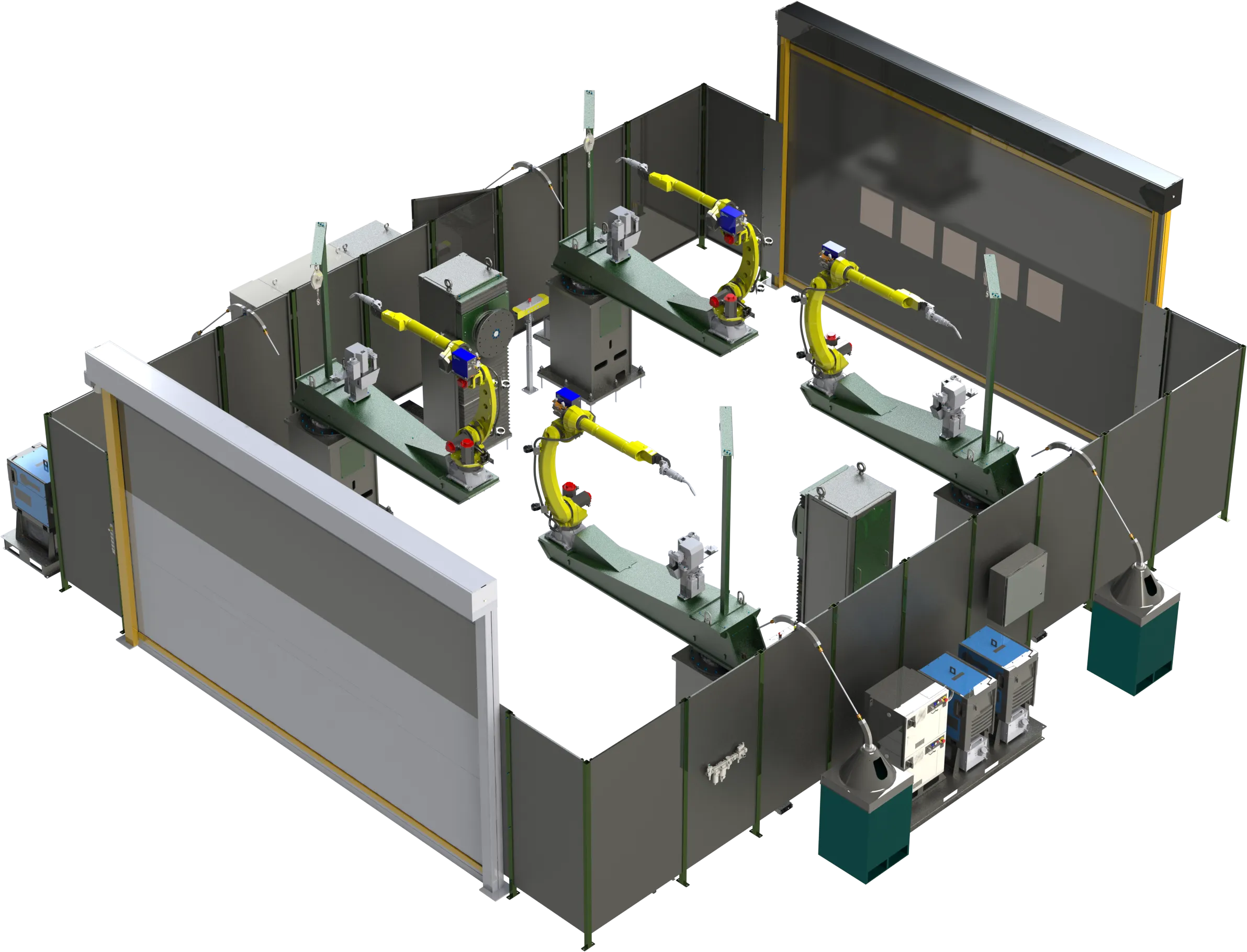

MWES designs and builds fully customized automation systems from robotic welding and palletizing to machine tending, vision inspection, and complete line integration. Every solution is engineered in-house, including mechanical and electrical design, software development, fabrication, and Factory Acceptance Testing. That means tighter control, faster delivery, and a solution built precisely for your process, not a one-size-fits-all system. Whether you’re upgrading a single station or launching a new production line, we deliver automation that works the way you need it to.

Automation to Move Your Industry Forward

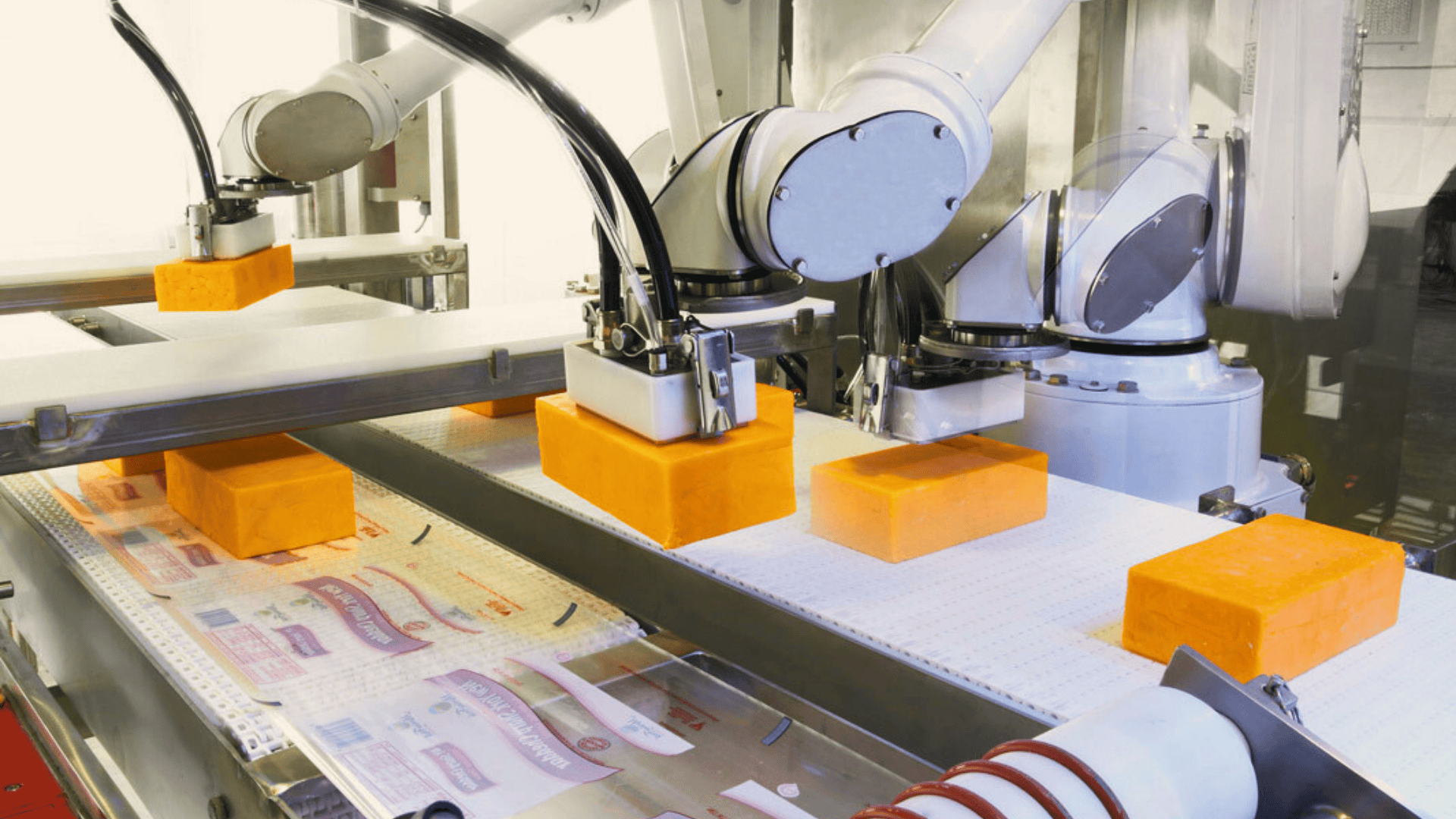

With deep experience across industries like food and beverage, aerospace, automotive, packaging, and general manufacturing, MWES delivers automation solutions built for real-world challenges like tight tolerances, regulatory compliance, workforce limitations, and evolving production demands. We understand your industry, speak your language, and design systems that solve problems others can’t so we can hit the ground running to deliver smarter solutions, faster.

Ongoing Support

for Every System

MWES provides long-term service and support for both new and existing automation systems. Our support includes preventative maintenance, emergency service, spare parts, upgrades, and on-site training whether you’re running MWES-built systems or third-party equipment. We approach service with the same engineering mindset that drives our automation design, helping you extend equipment life and reduce unplanned downtime with support that continues even after delivery or upgrades.