Heavy Equipment Manufacturing

- Home

- Industries

- Heavy Equipment Manufacturing

Over 30 years Optimizing the

automation & the production of heavy equipment

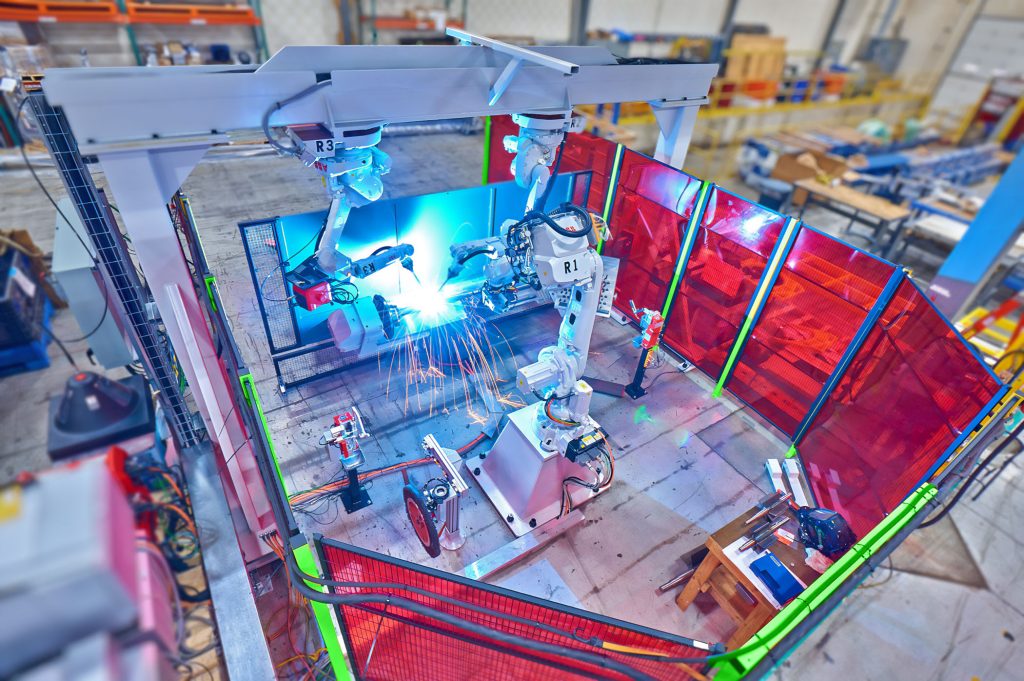

Robotic automation systems have become a mainstay in manufacturing heavy equipment. As far as safety and insurance claims go, relying on manual labor to handle large, heavy components is an unrealistic expectation. Additionally, robots reduce labor costs and increase competitiveness by repurposing manual labor and augmenting their capabilities. Robotics can be utilized for handling heavy parts and operator-assist devices for carrying assemblies through a factory decreasing the danger of injury to personnel and equipment.

Midwest Engineered Systems has for decades integrated automation systems for heavy equipment manufacturers. We have built automation systems that increase the quality, traceability, efficiency and throughput of manufacturing processes.

Automation Applications

heavy equipment Manufacturing Automation expertise

Frame Welding

Storage Tanks & Vessels

Structural Steel

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing