Skylift 3-Axis Welding Positioner

- Home

- Recent Projects

- Skylift 3-Axis Welding Positioner

Project summary

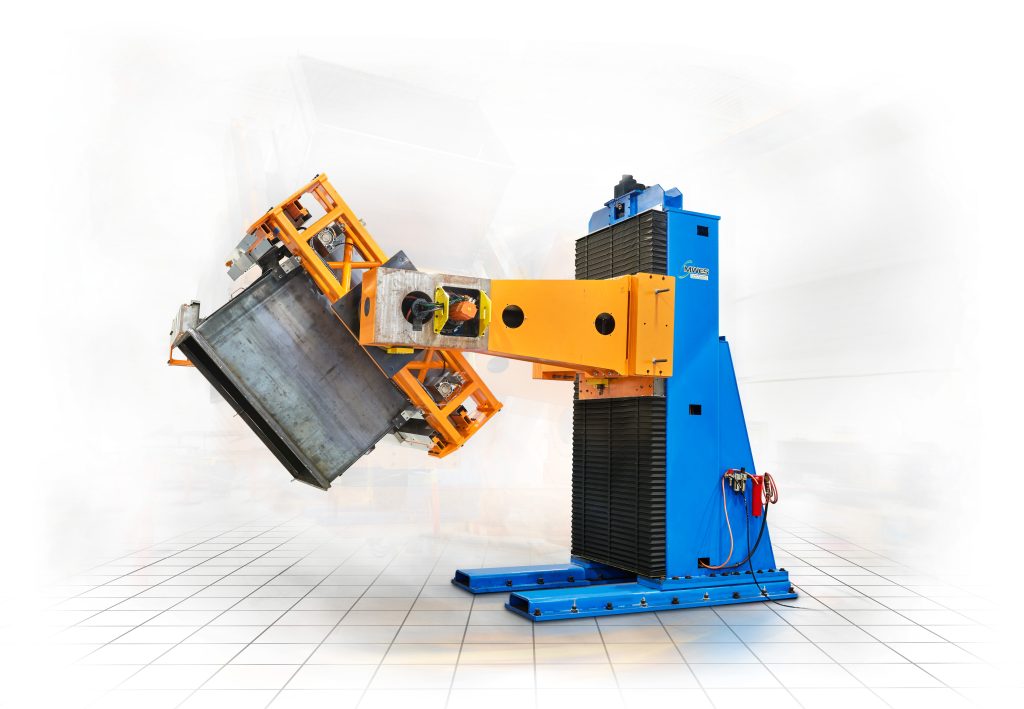

MWES designed and built a 3-axis servo welding positioner as part of a large trash dumpster bin assembly line.

The Challenge

Running welding operations on large, heavy parts requires a way to reposition the part to reach all the desired spots where the welding needs to be performed. Traditionally an overhead crane would be used however, cranes can be hazardous to the workers and are difficult to position consistently. This firm approached MWES to produce a common device to pick it up and orient the large bins weighing 600-1,000 lbs. without the use of a traditional crane.

The Solution

For our customer, MWES produced a floor-mounted 3-axis Skylift servo positioner and the applicable fixturing. The Skylift includes several part manipulator systems that accommodate both the operator for assembly functions and a welding robot for additional welding of large parts with no need for a traditional crane.

The Skylift positioner mounting platter can accommodate parts as heavy as 8,000 lbs and provides 360 degrees of rotation while the positioner arm can perform up to 180 degrees of rotation. The positioner arm and mounting platter axis are designed to be an external axis for a robot, which allows true coordinated motion with a welding robot. The ground cabling along with other required cables and tubing are routed through the center of the rotational axis and the lift axis has up to a 60-inch travel range.

Impact to the Customer

By eliminating the crane, the material handling time was cut in half and the safety of the overall system was increased to an operation that did not require certification for hoists, swinging mass, or operators to control and verify the safety during the positioning activities.

Midwest Engineered Systems has a wide range of experience in integrating welding positioner systems. If you’re looking to improve your assembly line throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

An industrial refuse dumpster manufacturer.