High-Speed Vision Inspection Systems

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- High-Speed Vision Inspection Systems

Track Your Processes with High-Speed Vision Systems

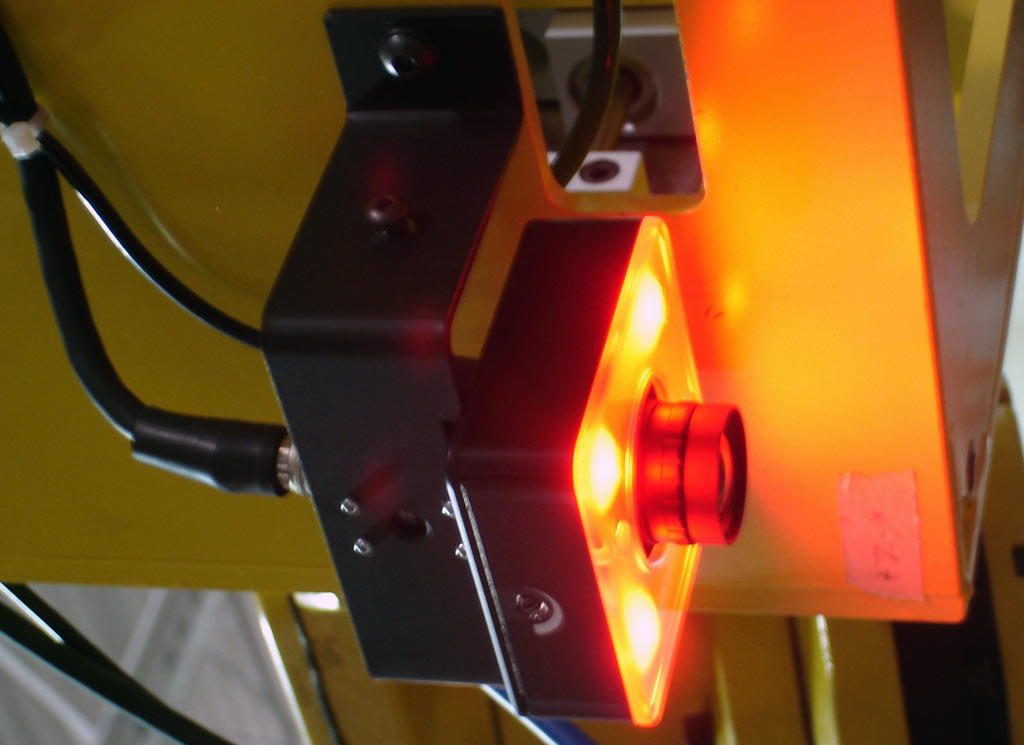

Vision systems display high-speed 2D or 3D maps of the manufacturing environment to assist robots in picking, placing, orienting, controlling, etc. which will improve throughput and consistency. Additionally, with the help of vision systems, they can verify parts for accuracy for quality control purposes.

Midwest Engineered Systems routinely utilizes high-speed vision inspection equipment in our manufacturing automation systems to fulfill our customers’ process needs. High-speed vision systems are sophisticated enough to eliminate the need to manually inspect and measure materials as they cycle through a system.

Vision systems are ideal in the food production industry by visually inspecting a part’s shape, quantity, volume and more. While coordinating with other automation systems to make any adjustments to the part accordingly. Vision systems would eliminate the need to have human operators staged along a production line doing those mundane tasks.

Track Defects & Part Variances with Vision Inspection Systems

Automating defect detection can have a great return on investment as automating this process is far more reliable and accurate than using human inspectors. These automated systems can be used in a wide range of applications and scenarios and can be easily incorporated into a conveyor system.

Human inspectors tend to find defects based on expectations and prior knowledge. That in turn makes the job done by humans inherently unreliable due to their subjective nature. With increasing demands for consistency and efficiency, humans performing this tedious, costly job can be replaced with computerized vision systems. These vision systems can help reduce human workloads and labor costs while increasing overall throughput.

Product Defects

Surface Defects

Packaging Defects

MWES builds and implements systems that take advantage of vision systems. Utilizing these systems provides our customers with greater cycle times and a great ROI. By using automated high-speed inspection vision systems, materials can be quickly and accurately checked for consistency in the production line. MWES’ inspection systems are custom-designed to incorporate different handling and feeding concepts for almost any part style.

Building the future of manufacturing, together

World-class Automation