Medical Lab & Pharmaceutical

- Home

- Industries

- Medical Lab & Pharmaceutical

Over 30 Years of expertise in

Automating our medical labs and pharmaceutical industries

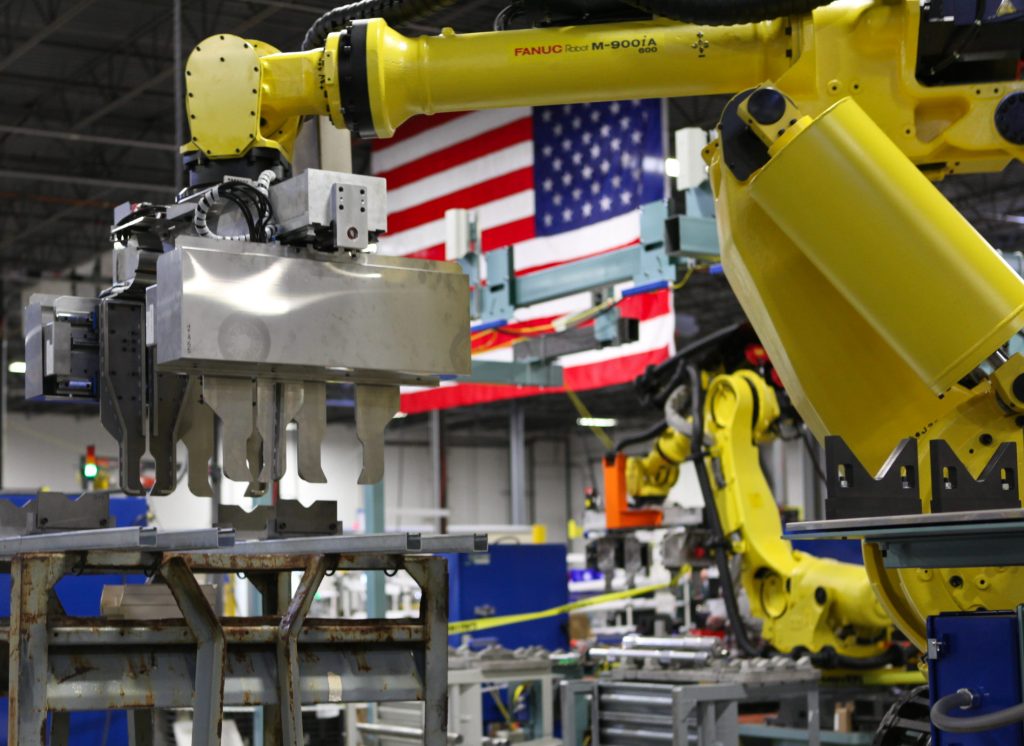

Robotic automation is used in medical and pharmaceutical labs all over the world to improve efficiency, accuracy and safety in various processes, such as research, quality control and manufacturing. Research facilities use autonomous mobile robots to transport materials and samples within and between labs, reducing human errors and contamination risks.

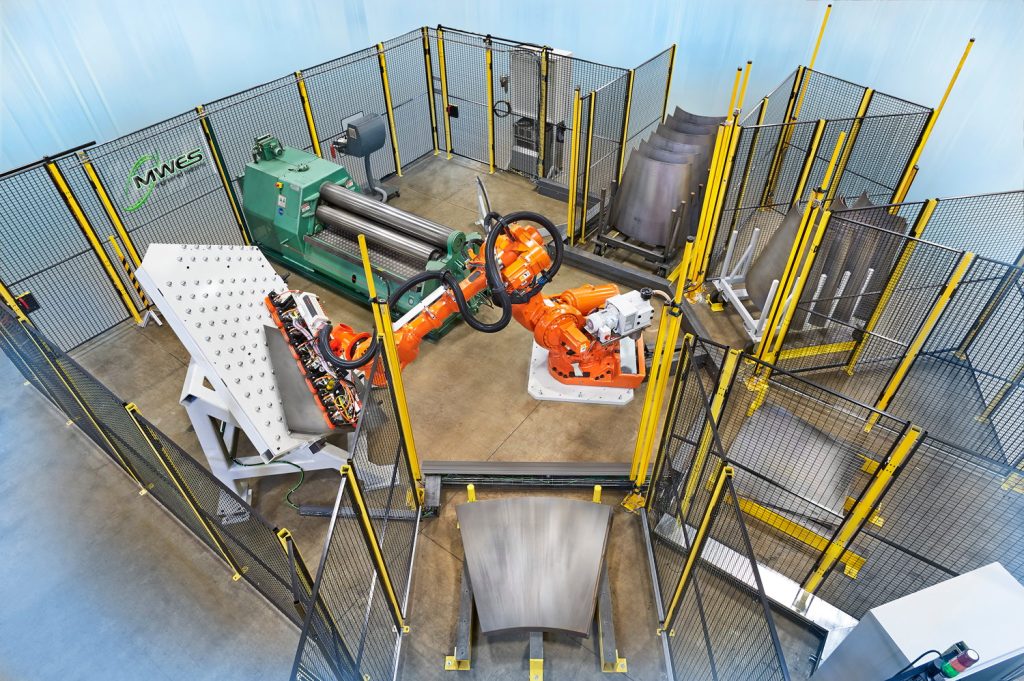

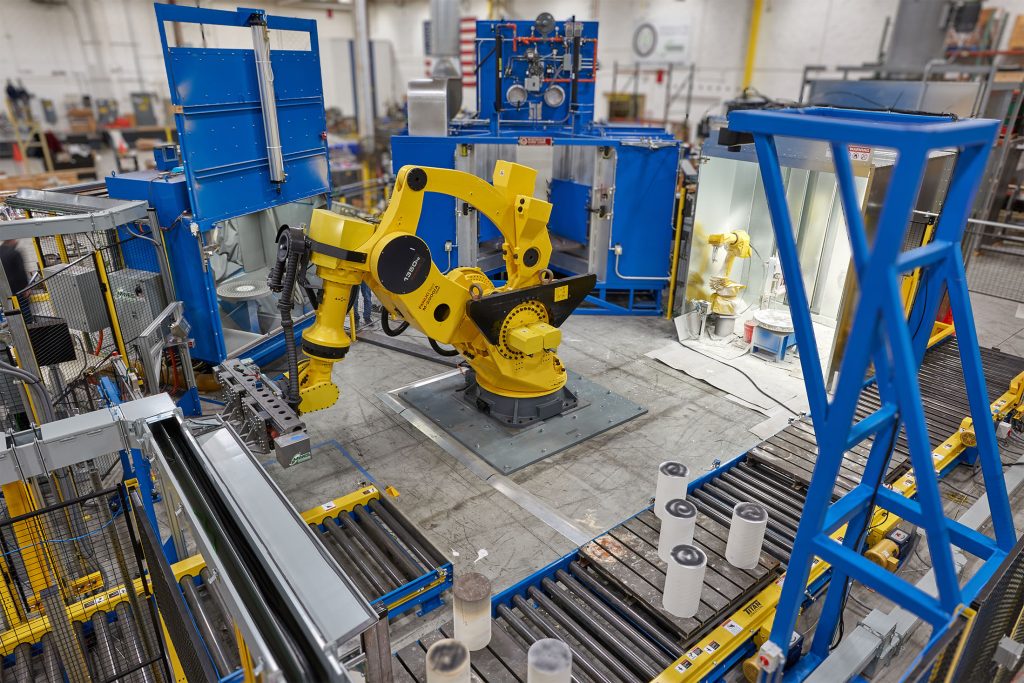

Midwest Engineered Systems has expertise in revolutionizing the medical industry whether through stand-alone process cells or entire production systems. We have integrated collaborative robots that work beside laboratory employees to perform repetitive, high-volume tasks, such as vial handling and mixing. As well as, FDA-compliant pharmacy automation systems that read prescriptions, fill vials, cap bottles, label containers and package medications with high precision and speed.

Our knowledge base extends across a variety of methods from high precision, high-speed manufacturing processes that hold the highest tolerances and quality to handling the packaging and material handling aspects in an automated fashion that increases throughput while reducing routing and shipping issues.

Automation Applications

Medical Lab & Pharmaceutical expertise

Medical Vial Filling

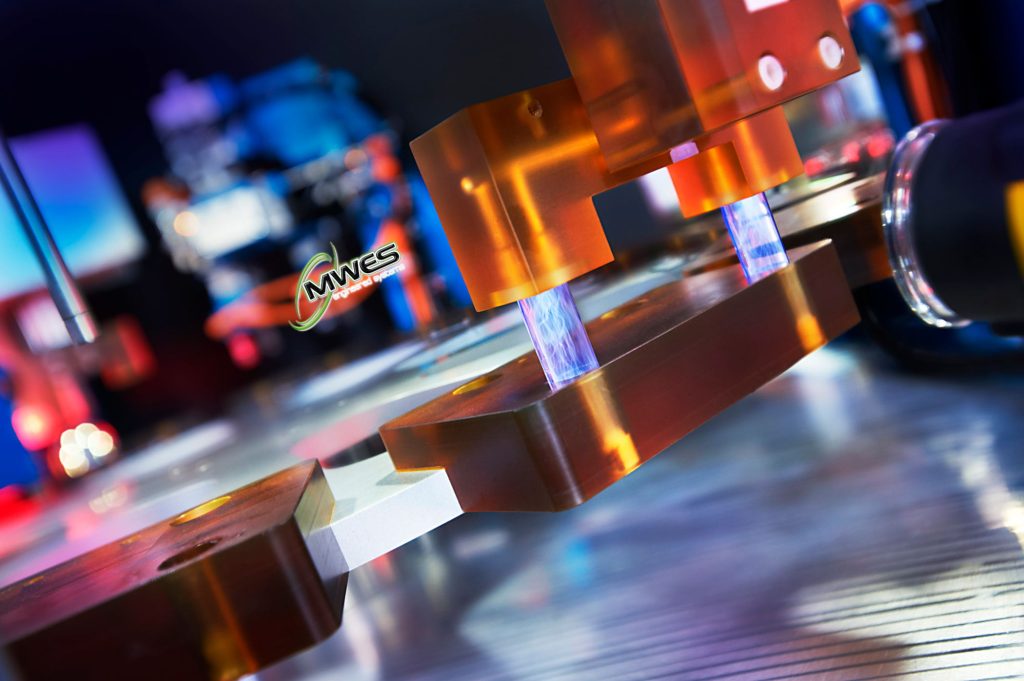

Medical Cartridge Coating Automation

Medical Component Assembly

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing