Plastics

- Home

- Industries

- Plastics

Over 30 Years Developing

automation that handles all things plastic

With the soaring costs of shipping overseas, manufacturers that work in plastics have been quick to embrace robotic automation as part of the sector’s continued onshoring efforts. Robot automation improves the quality, efficiency and safety of plastic manufacturing, all the while reducing plastic waste and the associated environmental impact.

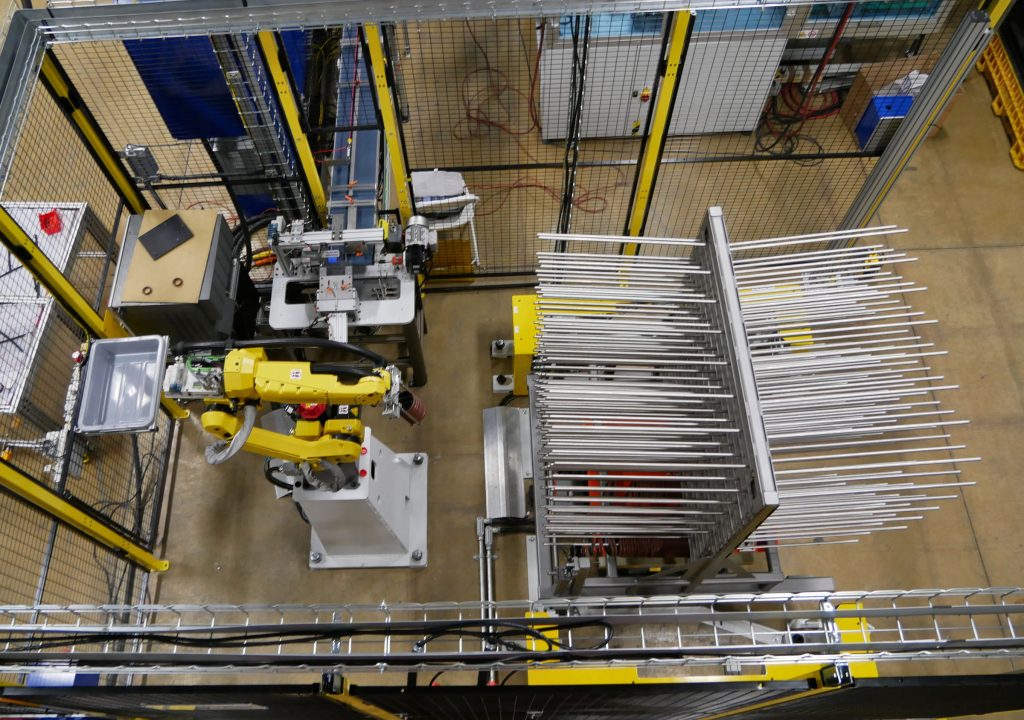

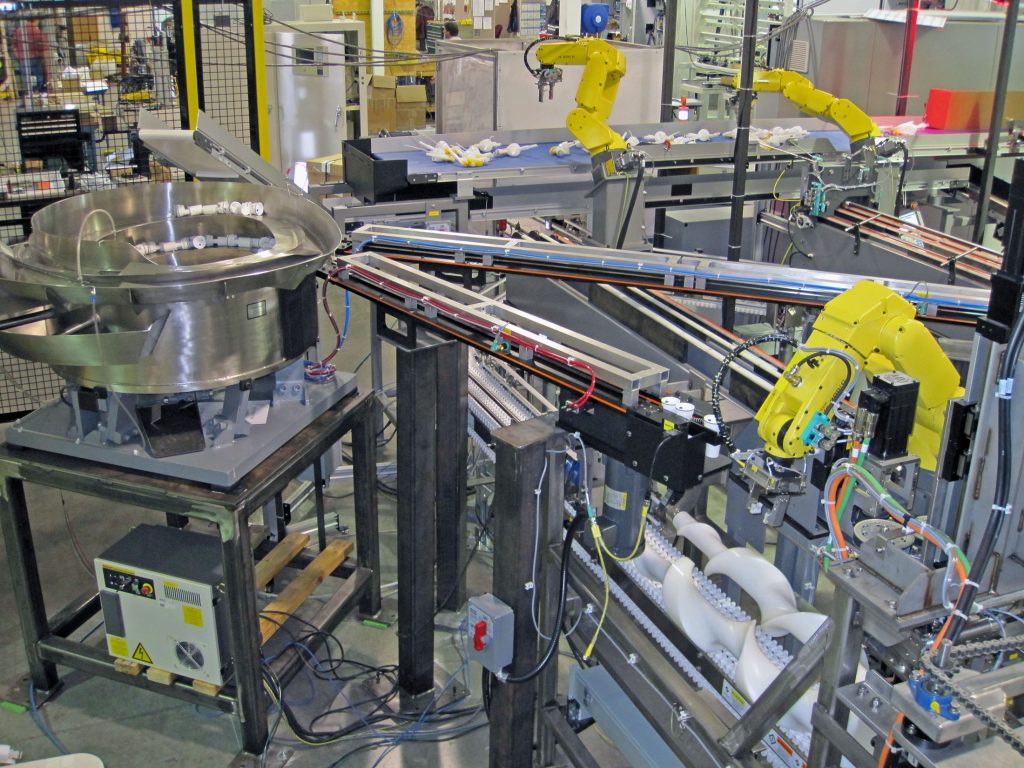

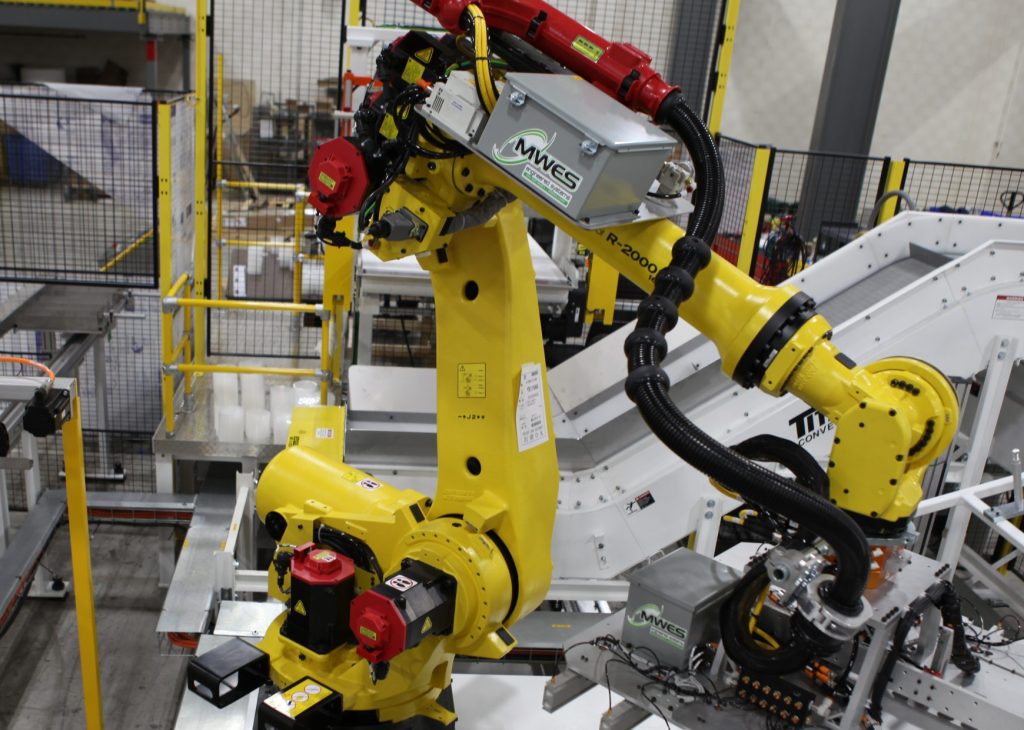

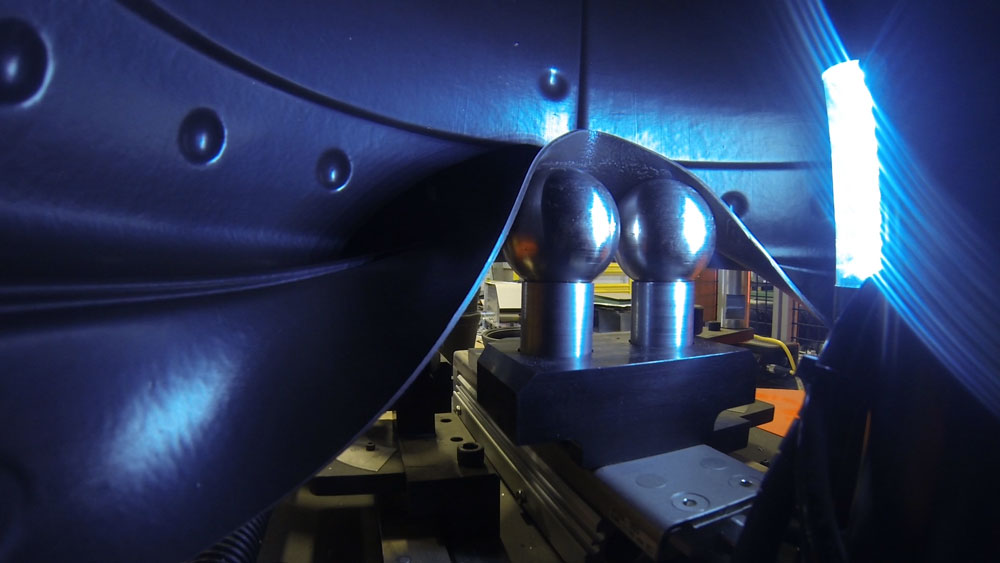

Midwest Engineered Systems has designed and developed various plastic component handling and assembly automation systems for a variety of firms. Our automation systems include part forming, spruce tree removal and injection molding.

Automation Applications

Plastic Parts Automation expertise

Forming Automation

Assembly Automation

Machine Tending Automation

Treating & Coating

Material Removal

Dispensing & Placement

Plastic Bag Assembly

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing