Gate & Flash Removal

- Home

- Industrial Automation Capabilities

- Robotic Material Removal

- Gate & Flash Removal

Robotically Automating Plastic Gate & Flash Removal Processes

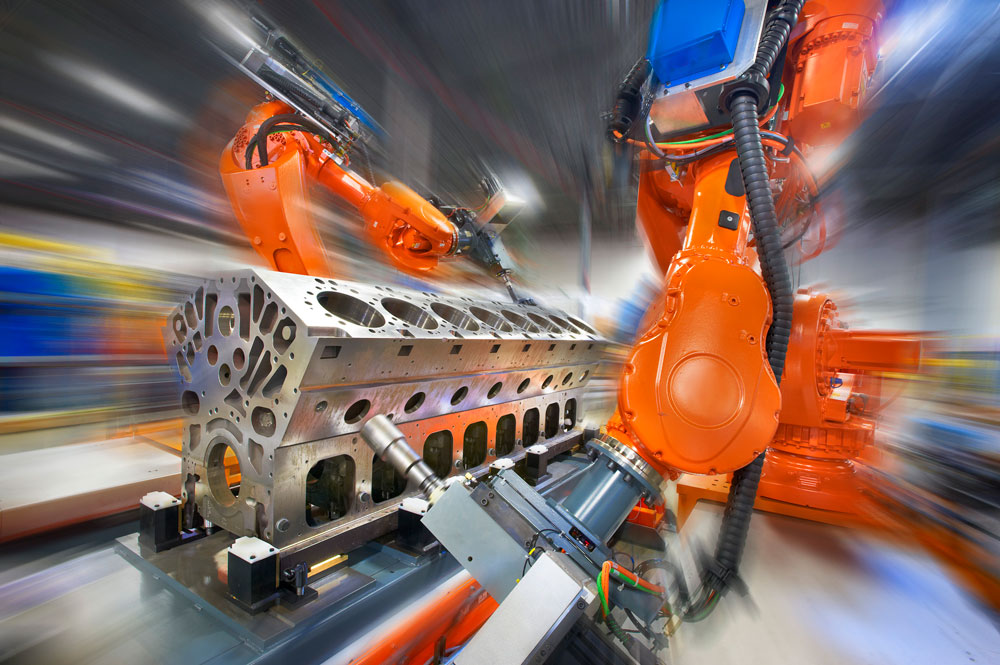

Plastic injection molding is a widely used process for producing high-quality plastic parts with complex shapes and in large numbers. One of the challenges of this process is the removal of excess material, such as gates and flashes, from the molded parts. Gates are the channels through which the molten plastic flows into the mold cavity, and flashes are thin layers of plastic that form along the edges of the mold due to leakage or high pressure. These unwanted materials need to be removed manually or mechanically after the molding process, which can be time-consuming, labor-intensive, and prone to errors.

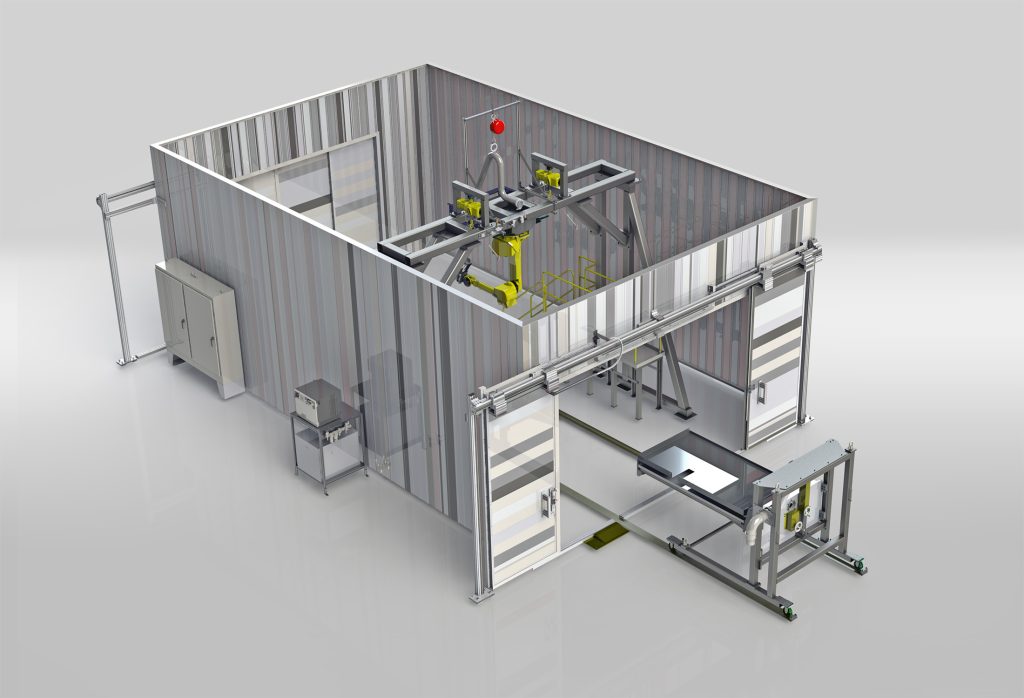

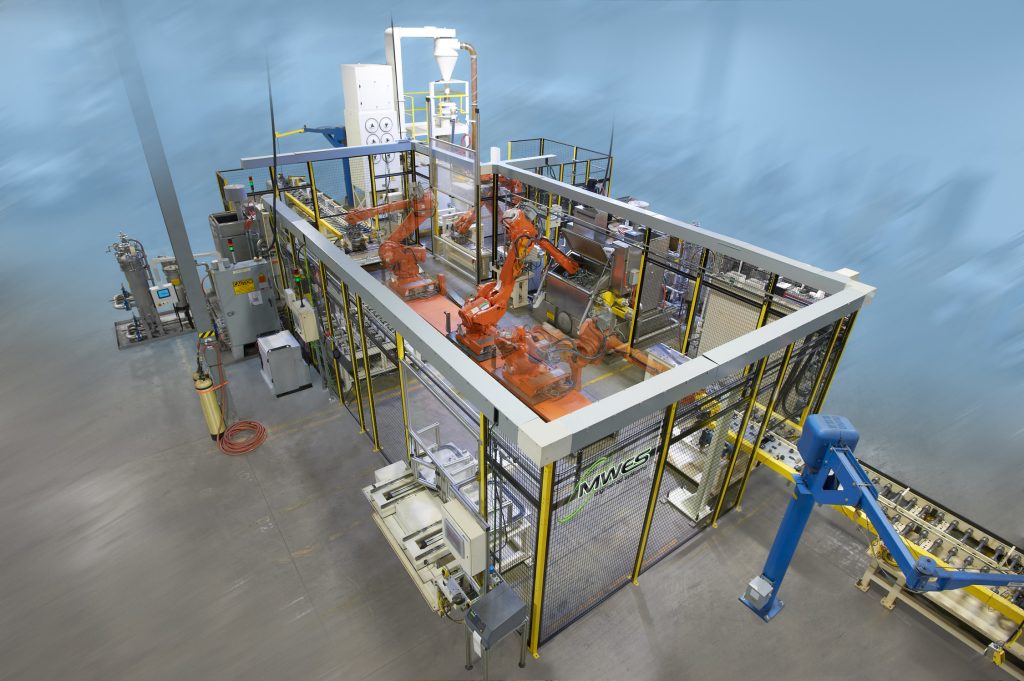

MWES has developed systems that use automated degating and flash removal from spruce trees. These systems use sensors, cameras, robots and cutting tools to detect and remove gates and flashes from the injection molded parts without human intervention. The automated degating and flash removal systems operate faster and more consistently than manual or mechanical methods, reducing cycle time and increasing output. Additionally, the automated degating and flash removal systems reduce the need for skilled workers to perform the post-molding operations, saving labor costs and improving worker safety. These systems also eliminate human errors and variations in the post-molding operations, ensuring improved quality with uniformity and accuracy of the molded parts.

The automated degating and flash removal systems are suitable for various types of plastic injection molding applications, such as automotive, medical, consumer electronics, and packaging. They can handle different sizes and shapes of molded parts, as well as different types of plastic materials. They can also be integrated with other automation solutions, such as robotic vision inspection, sorting, and packaging.

If you are interested in learning more about automated degating and flash removal systems, please contact us today. We can provide you with a customized solution that meets your specific needs and requirements.

Building the future of manufacturing, together

World-class Automation