Robotic Material Removal

- Home

- Industrial Automation Capabilities

- Robotic Material Removal

Bringing process together with

Robotic Material Removal Solutions

Upgrade your Material Removal With Robotics

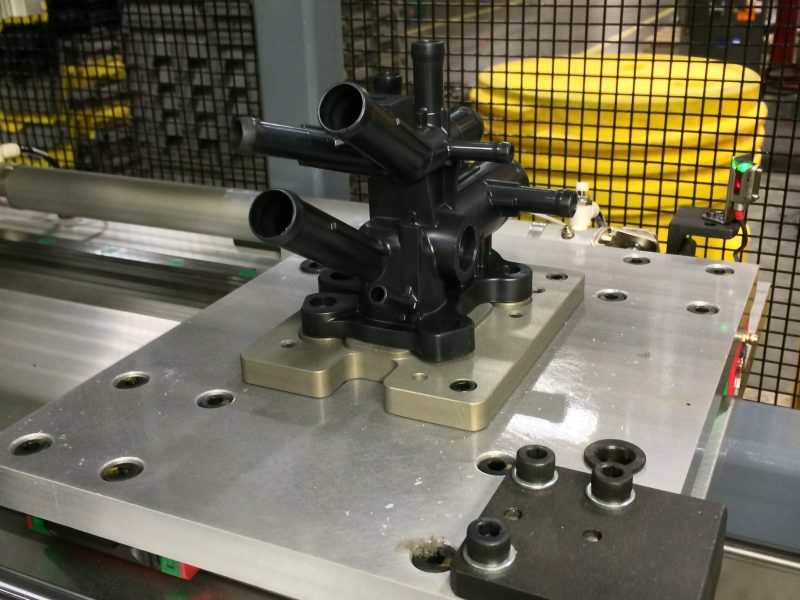

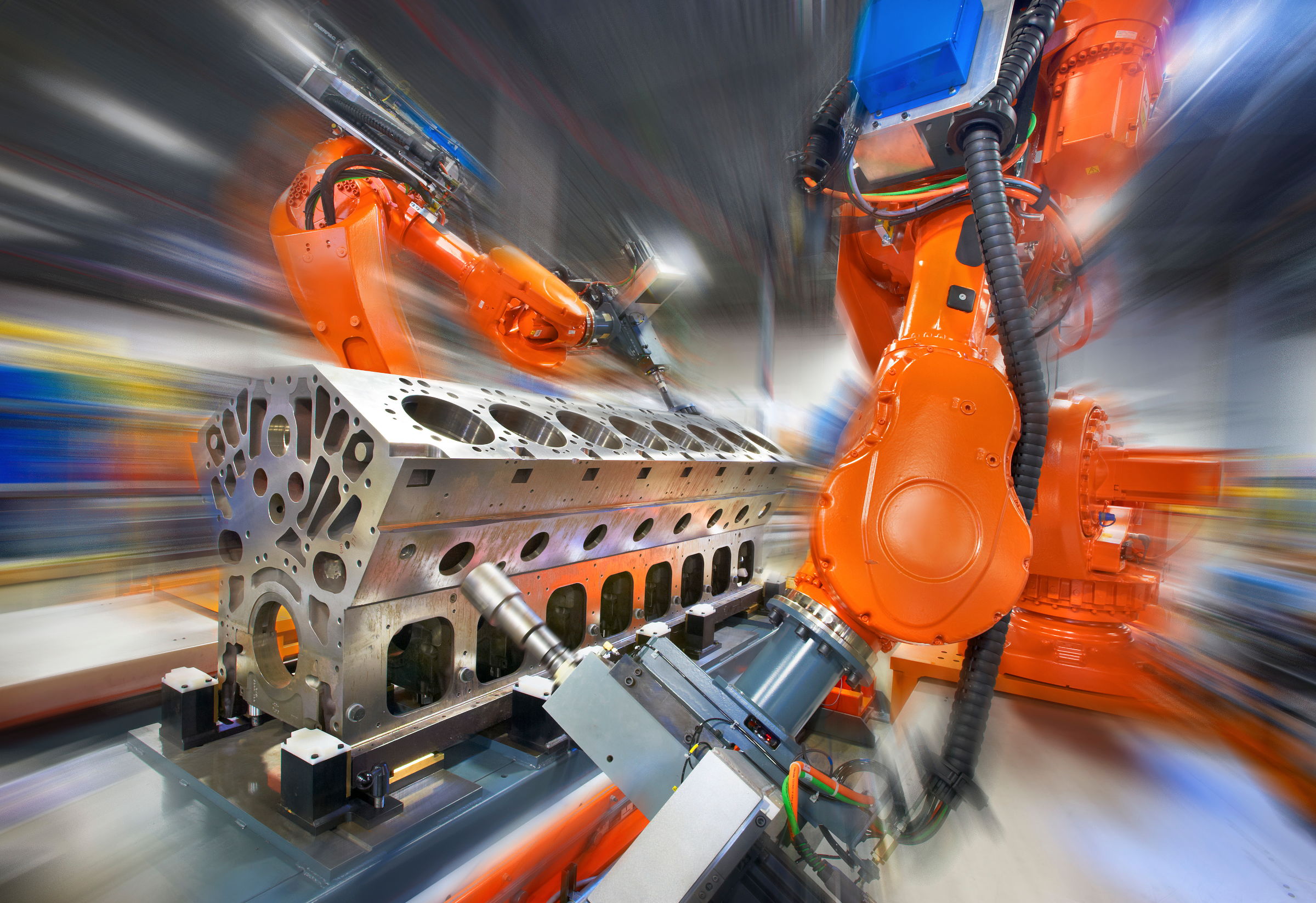

Material removal and finishing have been a manual and very labor-intensive process, and with labor shortages on the rise, robotically automating that process is the solution. Robotic material removal systems can be custom-engineered to make this application safe, consistent and economical for businesses both large and small. Automating metal removal, degating, and deflashing of castings, and even material handling applications can overcome a shortage of workers that many foundry and casting firms struggle with. Using cutting-edge technologies including the latest in robotic technology and machine vision, MWES can achieve desired casting finishing production and quality goals while producing more consistent parts and reducing reliance on manual labor.

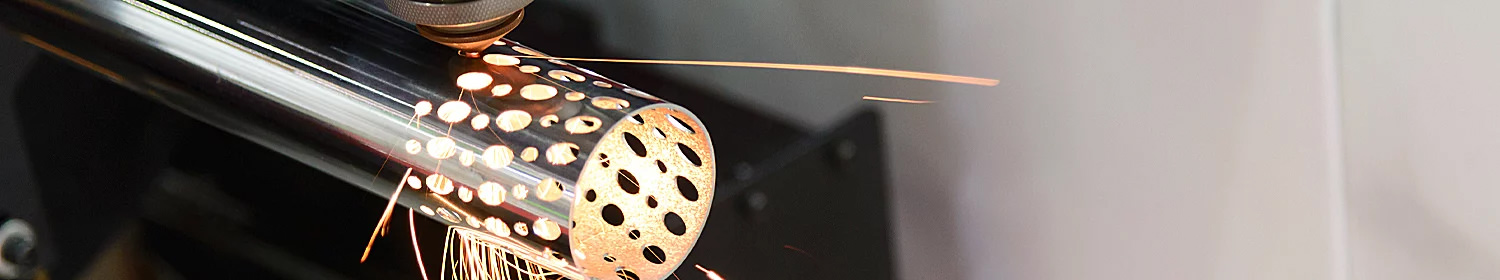

With the flexibility and articulation capabilities of modern industrial robots, robots can easily clear holes, process interior features or passageways and remove sand defects or parting lines. Furthermore, these automation systems’ heavy-duty pneumatic or electric spindles can be expanded using automated tool-changing capabilities for applications that require a large number of processes, increasing each robot’s utility.

Whether it’s high-volume production, the automation of high mix/low volume operations, or operating on extremely large castings, MWES has found ways to reduce the need for specialized fixturing and downtime attributed to resetting for different part runs. Robot systems are highly adaptable to production changes while reducing the number of part-specific, wear-susceptible tooling on the line. This flexibility comes from the ability to quickly and easily extend the systems’ processes in the software, instead of in the hardware. Further, the programming can now be done offline, minimizing downtime for production changeovers.

From large automated assembly lines to small drop-in machine tending systems, robotic material removal operations can be applied to manufacturing needs of any scale. Midwest Engineered Systems custom designs each robotic integrated system for your material removal operations. MWES has designed and installed hundreds of robotics-based systems from small startups to Fortune 500 corporations.

Building the future of manufacturing, together

The Areas where we can Help