INDUSTRY FOCUS

Recreational Vehicles

- Home

- Industries

- Recreational Vehicles

Over 30 Years Automating

The Builders of motorcycles, watercraft and more

With luxury leisure vehicle sales on the rise, more manufacturers are turning to new automation solutions to keep up with demand. Robotic automation increases productivity, quality and safety in vehicle component manufacturing such as chassis, frames and engine parts. Transitioning a manual manufacturing line to robot automation helps reduce labor costs and improves factory throughput.

Midwest Engineered Systems has extensive experience developing and integrating factory automation systems that construct parts for motorcycles, motorboats and more.

Automation Applications

Recreational Vehicle expertise

Flywheel assembly Operation

Midwest Engineered Systems designed a fully automated multi-station press that has a part rate of one assembled part every 50 seconds. The following methods, components and technologies were implemented and integrated to provide a comprehensive solution.

Motor Assembly Line Automation

Midwest Engineered Systems integrated a modernized manual manufacturing process with a suspended conveyance system for the assembly of outboard motors. MWES provided this firm with an updated assembly line that retained the manual workforce but provided a safe and ergonomic process.

Assembly Automation with AGVs

Midwest Engineered Systems integrated an automation system using autonomously guided vehicles (AGVs) to eliminate the need to design and build complex conveyor systems. The AGVs would navigate a lengthy preexisting motor assembly process and would have to lift, carry and orientate outboard motors or long block engines throughout the build cycle.

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing

Recent Projects by MWES

Refrigerated Storage Tending with AS/RS Buffer System

MWES provided our customer with an automated layer-picking system that consisted of a conveyor...

Robotic Automation for Brewing

PROJECT SPOTLIGHT

Robotic Bottle Depalletizing System

Home Pages Recent...

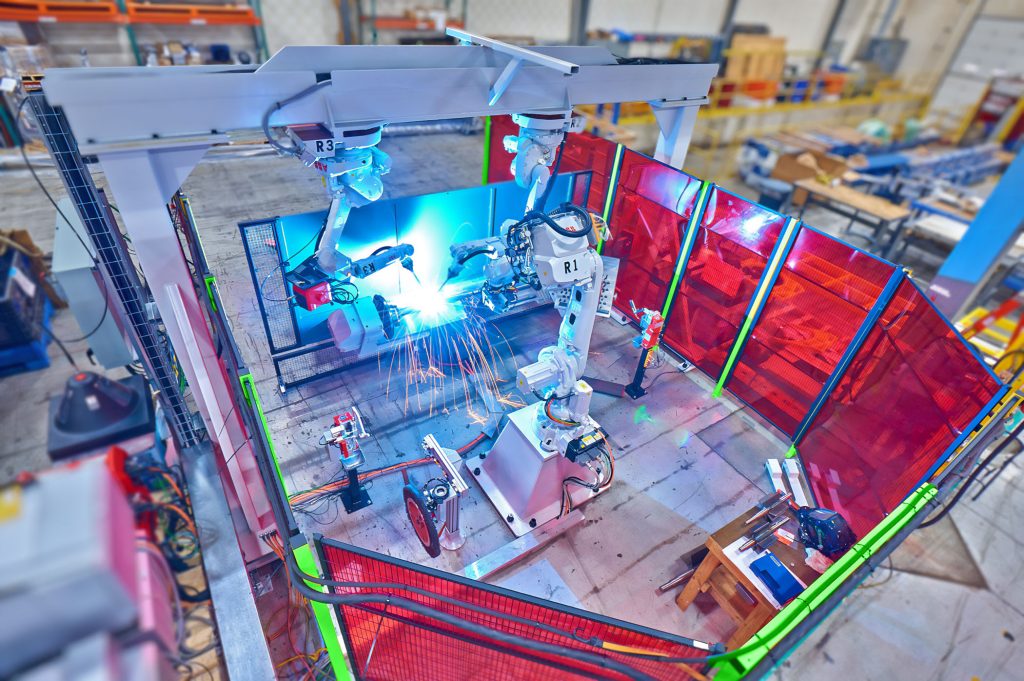

Robotic Multi Vane Rotor Assembly Welding

MWES integrated a robotic welding cell to manufacture multiple varieties of rotor vane configurations...

Order Handling with a Layer Picking Robot & AS/RS Buffering

MWES integrated an order kitting system for a cold storage facility that utilizes a layer-picking...

Robotic Adhesive Dispensing System

MWES built an automation system that would robotically apply a small amount of 3M Scotch-Weld...

Robotic Layer Picking System

We provided this customer with an automated layer picking system, equipped with a robot and...

Aerial Lift Weldments Automation

MWES provided this manufacturer with two robotic welding cells for producing industrial aerial...

Robotic Case Packing Cell

MWES provided a machine to erect the customer’s pre-glued auto-bottom boxes and pack individual p...

Robotic Frame Welding Automation

MWES provided this manufacturer with a robot welding cell that manufactures large generator...