Proof of Principle Testing

- Home

- Our Process

- Proof of Principle Testing

Providing firms production analysis to

Explore the performance potential at a fraction of the cost of a complete system

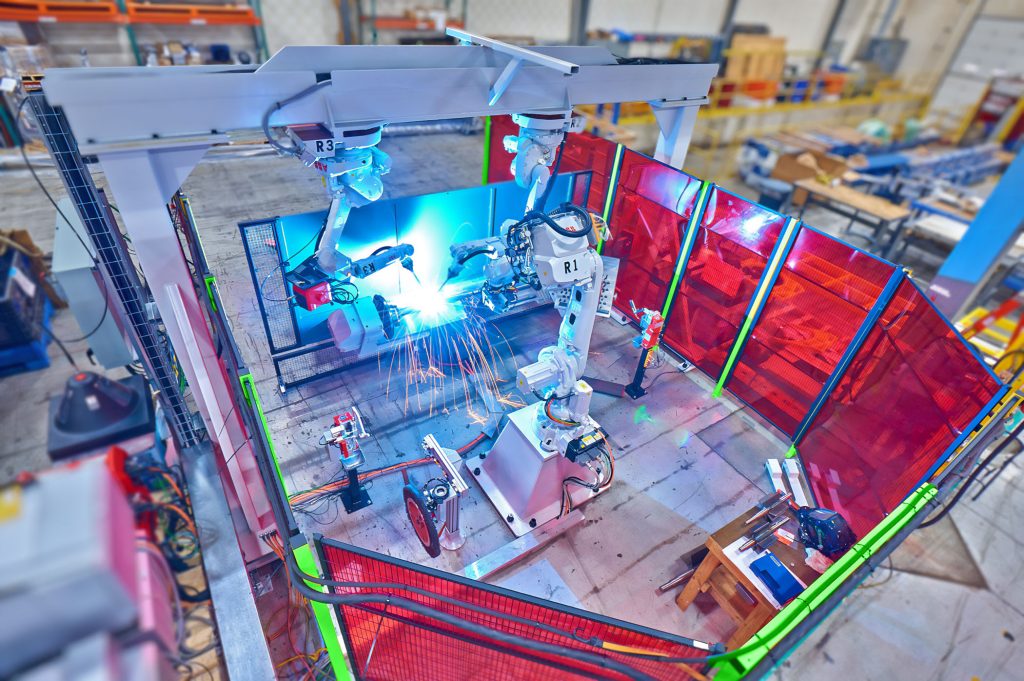

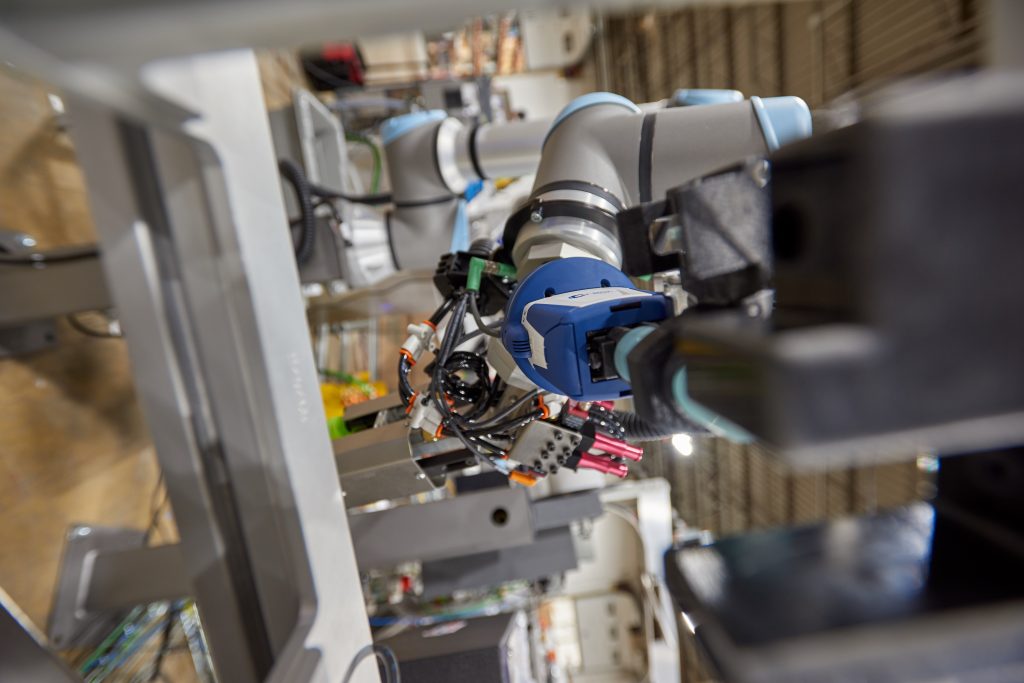

With its Proof of Principle (PoP) testing program, Midwest Engineered Systems (MWES) takes the estimation of an automation system’s effectiveness from simulation to near real-world operation. Midwest Engineered Systems offers the ability to experience the performance of an automation system with real parts and production conditions before significant investment in a production automation system is made.

Relying on over 30 years of innovative and efficient production automation systems development, MWES analyzes your current production process and develops the best automation solution within the project’s design and financial constraints. From there, we produce a physical prototype of the system that takes into account the most important aspects of the potential future automation system. This installation is designed from the start to operate on your production-ready parts. Once the system is up and running, it’s tuned to its best performance within everyday production floor operation constraints and overall system longevity.

Customers are invited to view the system in operation to fully understand its capability and make adjustments necessary to fit with current upstream and downstream operations. Otherwise, a video of the system can be provided for proof of operation.

At the completion of the PoP, MWES will provide a detailed performance analysis of the process, including important considerations and recommendations, as well as the metrics necessary to make an informed decision as to whether pursuing automation for this process is worthwhile this time.

Investigating whether an automation system is right for your production system can be confusing and nebulous. Partnering with a highly experienced, trustworthy integrator like Midwest Engineered Systems can help navigate the complexity of automation possibilities.

Contact MWES to learn how we can develop and test potential solutions not just in simulation, but in the real world, to reduce uncertainty and determine if automation is right for your operations more efficiently.

Building the future of manufacturing, together

How we can help your business with

The MWES Process

Our Process

With each automation project, Midwest Engineered Systems implements a project management process that walks through the steps for successful equipment integration.

Process Development

Our approach to automation process development is to first evaluate the firm’s current production operation and understand the company’s process needs.

Proof of Principle Testing

We offer the ability to experience the performance of an automation system with real parts and production conditions before significant investment in a production automation system is made.

Consolidating Multi-Line Production

We can utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution.

Engineering for Manufacturability

We can help reduce the costs associated with automation by analyzing and suggesting product and process modifications.

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing