Easy-Arc Welding Positioners

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Easy-Arc Welding Positioners

Improve your Output with Welding Positioners

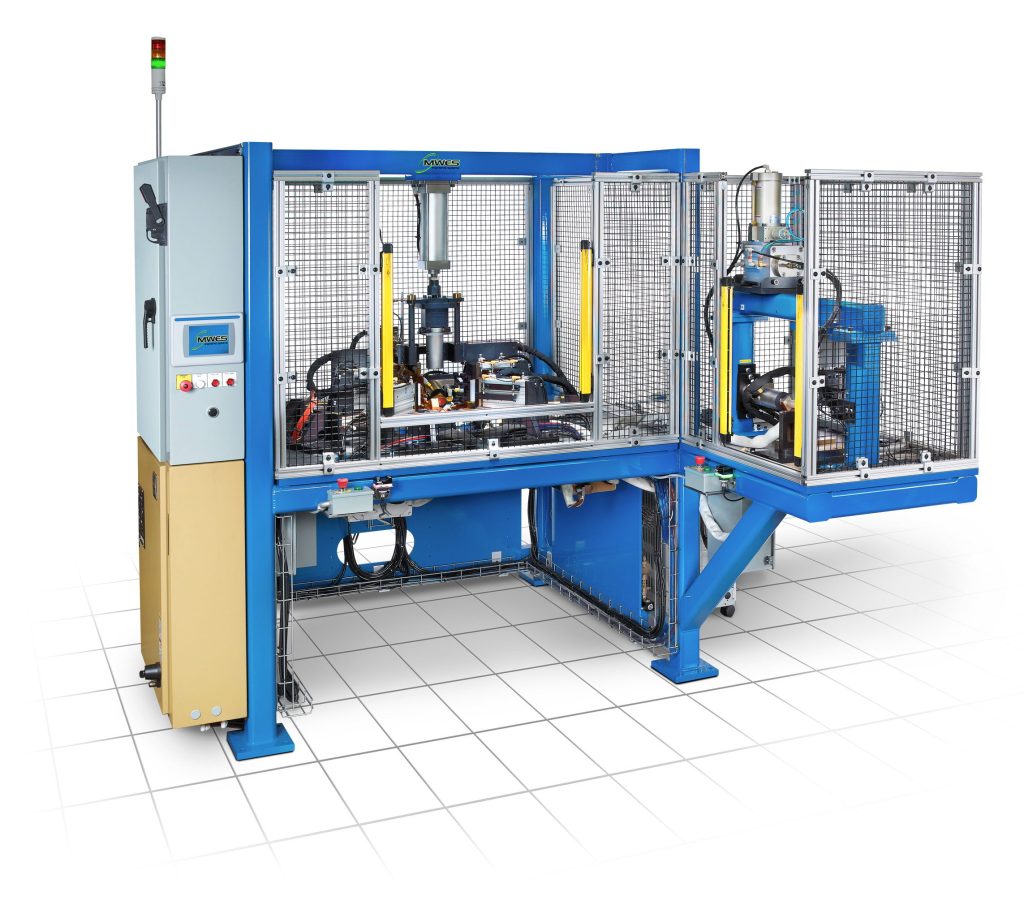

Easy-Arc welding positioners are one of Midwest Engineered Systems’ most popular options for robotic welding solutions as positioners assist in creating efficient and consistent welding output. MWES offers a variety of positioner types, with each one providing a solution for a different application for arranging parts into optimal welding positions. The positioning operation can be conducted even in the most challenging circumstances and applications.

Advantages to Welding Positioners

There are many benefits and advantages to using welding positioners for your welding applications. Their capabilities are unsurpassed when it comes to movement and flexibility. Our automated positioners offer an articulation range from 1 to 3-axis, and they can handle a part payload from 1,000 kg and a wide range of part dimensions. The positioner’s precision can produce optimal weld seam quality.

Additionally, they can tilt, turn and rotate workpieces 360 degrees as well as lift workpieces vertically. They can consistently hold, arrange and move workpieces and be deployed for robotic and manual welding applications. Positioners contribute to precision and safety in factory environments that require welding operations. Additionally, they eliminate a danger present for workers and the costs associated with them.

Welding Positioner Types

MWES utilizes a combination of stock positioners and our custom-built welding positioners. The stock positioners are produced by leaders in the welding industry and our custom-built positioners are scalable to your specific application and requirements.

Extra-large Capacity Positioners

We also offer the extra-large SkyHook two-axis robotic weld positioner that has a capacity of up to 30,000 kg parts. This positioner also works with both servo motors and variable frequency drives with external axis control from either robot control systems or PLC control. These options make this positioner easy to integrate into established factory systems as well as new ones. The two-axis motion and continuous rotation options allow for a few unique capabilities. These extra-large capacity welding positioners can precisely arrange the largest parts, such as those used in robotic welding, deburring and rough machining.

Recent Welding Positioner Project

Project for a Dumpster Rental Company

Rely On MWES For Your Welding Positioners

When it comes to your welding needs, MWES is sure we have what you’re looking for. We are here to answer your questions about your welding projects and what equipment will best serve your intended purposes. Contact us today to discuss which welding positioner best matches your welding applications and specific industry requirements.

Building the future of manufacturing, together

World-class Automation