White Papers

- Home

- White Papers

Educating our customers with

Robotic automation White Papers

Industrial robotics and automation integration is a specialty that’s deep and wide. It’s easy to get lost in the process of researching a project. As a long-time automation integrator, Midwest Engineered Systems understands this all too well. We’ve put together these free downloadable resources to help customers understand the industry.

Grow Your Process with Cobot Integration - White Paper

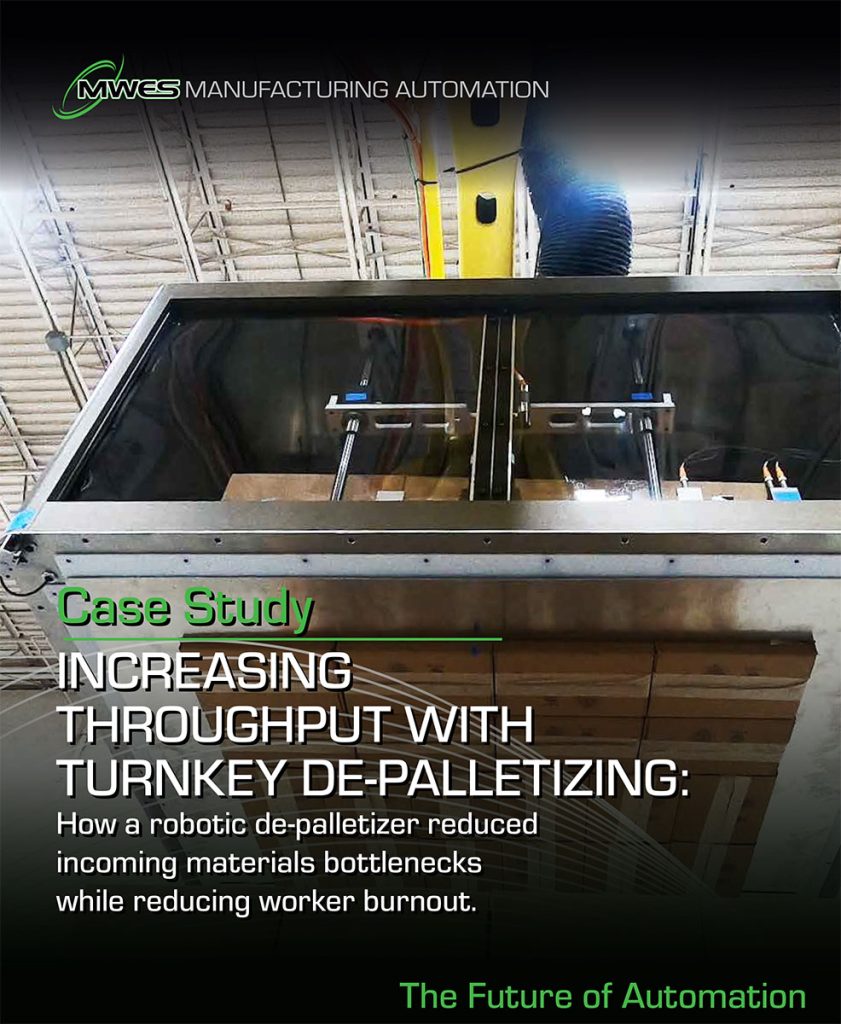

Increased Throughput with Turnkey De-palletizing Case Study

Benchmarks for Selecting a Systems Integrator - White Paper

The Best in Bending - White Paper

Determine Economic Feasibility for Robotic Bin Picking - White Paper

Consolidating Production Processes with Automation - White Paper

Implementing Robotic Arc Welding Automation - White Paper

Force/Torque Automation - White Paper

Is Robotic Welding Right for Your Operation? - White Paper

Proof of Principle Automation Testing - White Paper

A Guide to Process Development - White Paper

Checklist for Automation RFQ - White Paper

AS/RS Buffer Systems Can Streamline Kitting - White Paper

If you would like to speak with an experienced applications engineer about your automation project, please contact MWES today!

Building the future of manufacturing, together

How we can help your business with

The MWES Process

Our Process

With each automation project, Midwest Engineered Systems implements a project management process that walks through the steps for successful equipment integration.

Process Development

Our approach to automation process development is to first evaluate the firm’s current production operation and understand the company’s process needs.

Proof of Principle Testing

We offer the ability to experience the performance of an automation system with real parts and production conditions before significant investment in a production automation system is made.

Consolidating Multi-Line Production

We can utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution.

Engineering for Manufacturability

We can help reduce the costs associated with automation by analyzing and suggesting product and process modifications.

Why work with us

A trusted partner in manufacturing

Team Members

100+

Systems Built

4,000+

facility sq. feet

100,000+

RIA Robot Experts for

12 years

The latest updates from MWES

Blog & News Articles

Automating the Modifications to Fully Built Military Equipment

Automating Pharmaceutical Applications in an AI World

Midwest Engineered Systems Expands with a New Building Purchase

Embracing Robotic Automation to Address the Generational Skills Gap

Automated Bag Making with Web Handling Systems

The Role of Robotic Automation in Enhancing Military Equipment Manufacturing

The Enduring Relevance of Polar Robots in Modern Manufacturing

How MWES Safeguards Intellectual Property for the Defense Industry