Equipment Retrofits & Upgrades

- Home

- Industrial Automation Capabilities

- Web Handling & Converting

- Equipment Retrofits & Upgrades

Keep Your Obsolete Systems Running with a Retrofit & Upgrade

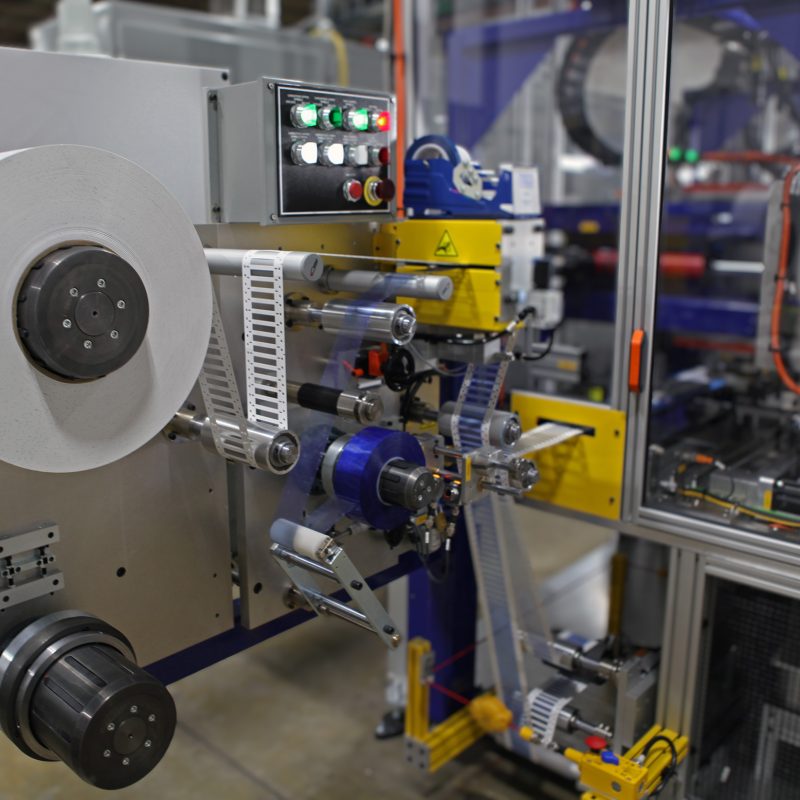

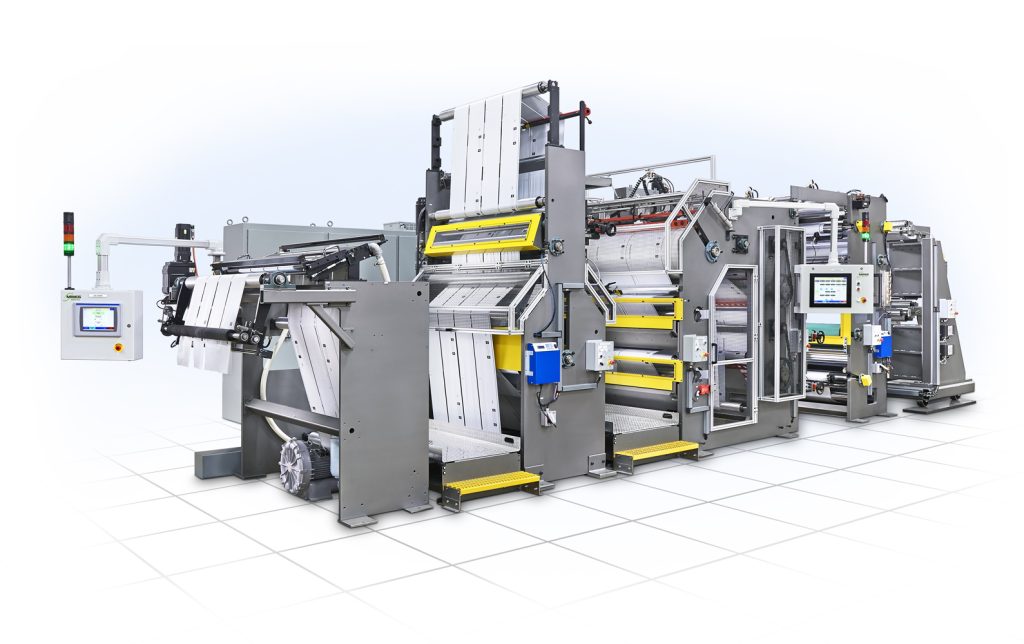

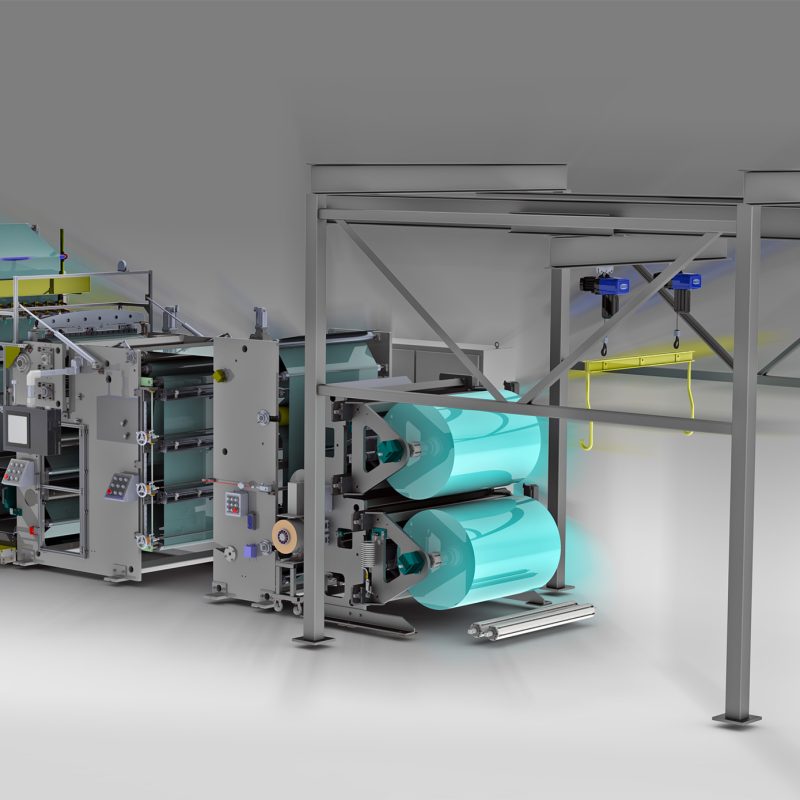

Midwest Engineered System’s extensive experience with unique drive systems and machine control methods positions us to handle operational upgrades, retrofits and additions, to both new and existing web converting and automated material handling equipment. Considering the steep upfront cost of a new web handling automation system, retrofitting and upgrading a system might be the best solution for your application.

Our extensive experience in a variety of industries gives us a unique ability to assist with these applications. With today’s rapidly changing technology, automation and robotic systems will require an upgrade at some point in their service life.

System Upgrades

- HMI and PLC programming upgrades

- System modernization

- Machine component upgrades

- Drive systems integration and tuning

- Control configuration updates

- Replacement of obsolete equipment

- Line speed improvements

- Performance improvements

System Retrofits

- Drive and control systems

- Servo control systems

- Robotic programming and cell modifications

- Software or programming upgrades

- Factory automation systems

- Obsolete systems

- Machine modifications

- Equipment relocation

MWES has provided thousands of upgraded and retrofitted systems to customers requiring design and build assistance. As with our other systems, the engineering staff at MWES consults with each customer to thoroughly evaluate an existing system and determine the necessary functionality. Updated solutions offer enhanced performance, better ergonomics, cleaner operation and improved maintainability. In addition, customers can retain or even increase the value of existing systems without significant investment or downtime.

If you want to upgrade your web handling automation system for improved throughput or modernization, please contact us today!

Building the future of manufacturing, together

World-class Automation