INNOVATION THROUGH AUTOMATION

Indexing Ferris Wheel Weld Cell

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Easy-Arc Standard Welding Cells

- Indexing Ferris Wheel Weld Cell

EASY-aRC Welding Services

System Overview

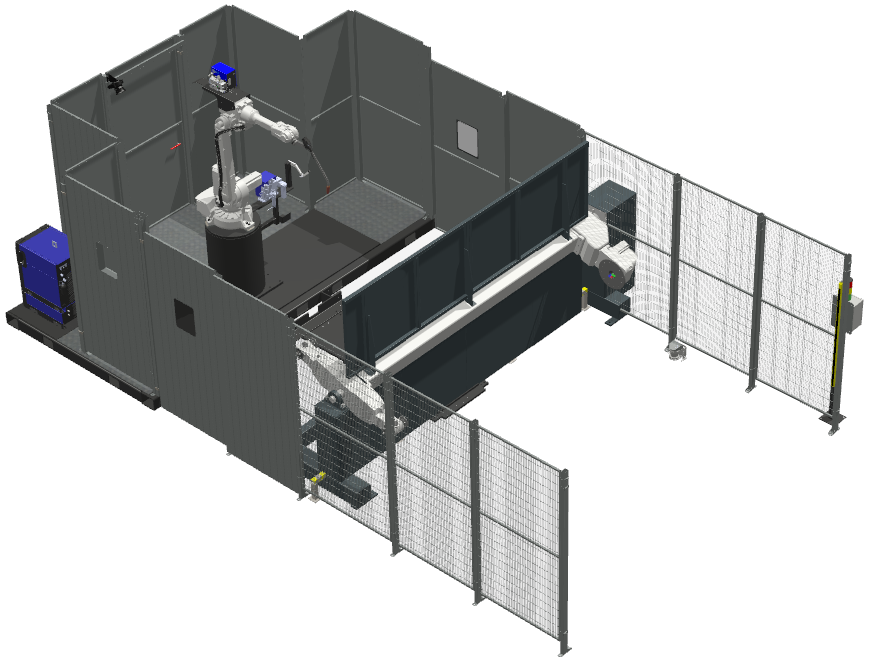

The Indexing Ferris Wheel Welding Cell is an automated welding system that consists of a rotating table with two or more stations, up to two robots and a safety enclosure. The table rotates to bring the workpieces to the robot, while the other stations are used for loading and unloading. This allows for continuous welding without interruption. This welding cell can reduce cycle time, improve weld consistency, lower labor costs, and improve overall worker safety.

- This weld cell comes with a full range of safety features and can accommodate two robots

- The loading zone of the cell is available in two variations: roll door or light curtain

- Rapid changeovers and high productivity are made possible by adaptive software and the high-speed drives of the positioners

- The positioners are offered in three variants and are designed to handle fixtures weighing up to 1,000 kg.

Featured Project

ROBOTIC FRAME WELDING

This system included one robot and one 2-sided, interchanging, welding positioner, as well as custom designed fixturing.

SYSTEM SPECIFICATIONS

- Two processing stations

- Component manipulation using rotation axis

- Load capacity up to 1,000 kg

- Station change via vertical rotation

| Permissible load capacity | 300 / 600 / 1000 kg. |

| Free-turning diameter | 1000 / 1000, 1400 / 1200, 1400 mm |

| High operating range | 950 / 950 / 950 mm |

| Min. station change time | 3.1 – 3.7 seconds |

| Max. station change time | 3.8 / 3.7 / 3.7 seconds |

| Repeatability | +/- 0.05 mm |

Robotic Welding Partners