Automotive

- Home

- Industries

- Automotive

Over 30 Years Developing

Automotive Manufacturing Automation Systems & Processes

Robotic automation has for decades been synonymous with the automotive industry, as it enables faster, safer and more efficient automobile assembly operations. With the increased complexity of today’s automobiles and the desire to avoid costly defect recalls, let alone the high costs of unionized workers, more automotive suppliers are turning to robotics to produce parts. Robotic systems have advanced enough that virtually every step in the supply chain and assembly process can be automated.

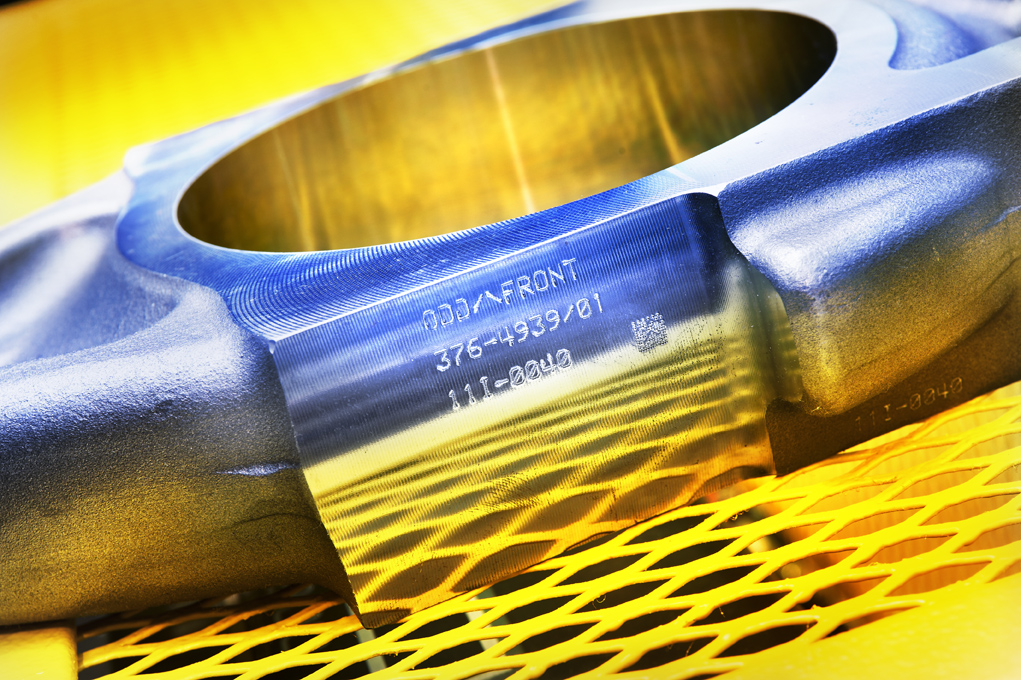

Midwest Engineered Systems has experience developing and integrating factory automation systems for automotive parts suppliers. We have provided automation solutions that have paved the way for improving vehicle quality and consistency while keeping ongoing production costs down.

Automation Applications

Automotive Automation expertise

Flame Treatment Operation

Component Assembly, Testing & Inspection

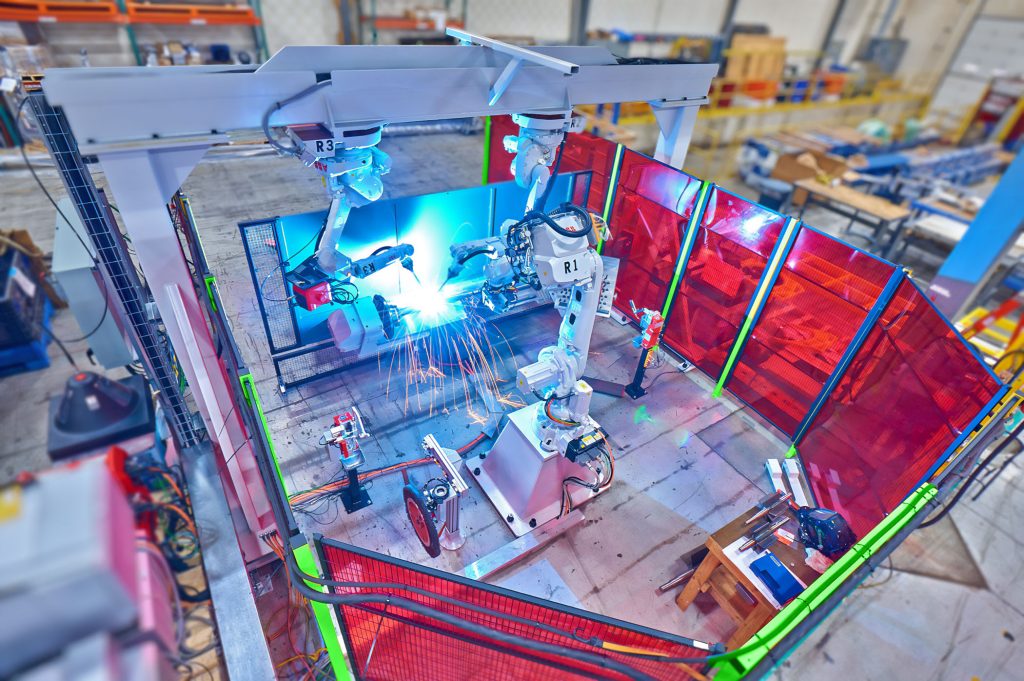

Component Welding

Ultrasonic Welding & Assembly

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

160+

Team Members

4,000+

Systems Built

198k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing