Part Assembly Automation

- Home

- Industrial Automation Capabilities

- Assembly Automation

- Part Assembly Automation

Automate Part Assembly for consistency & Accuracy

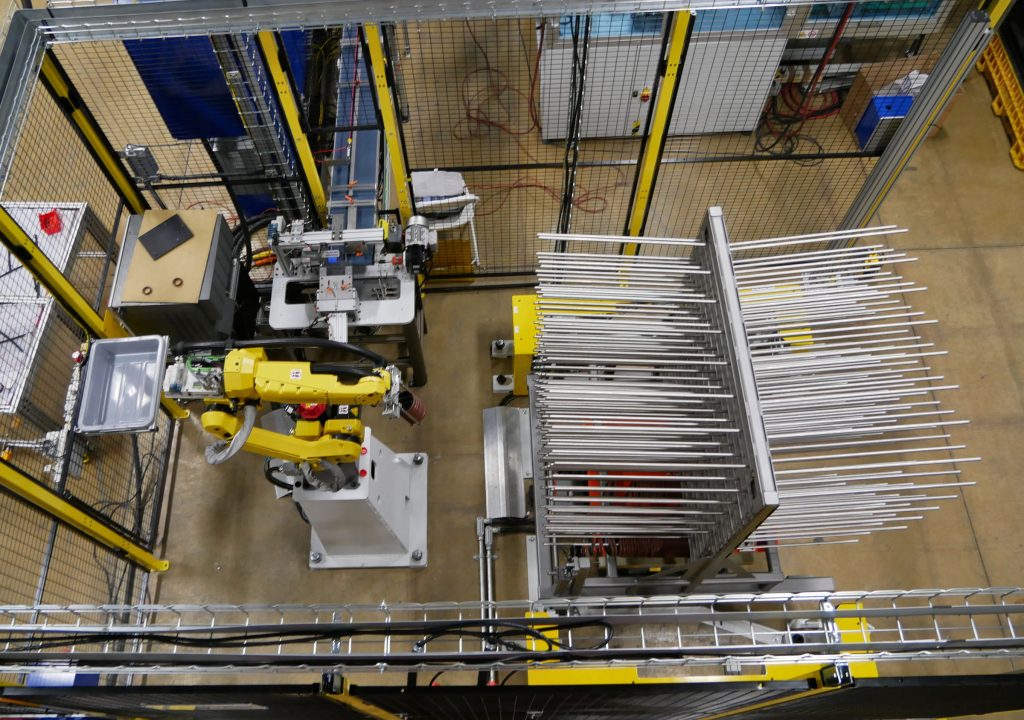

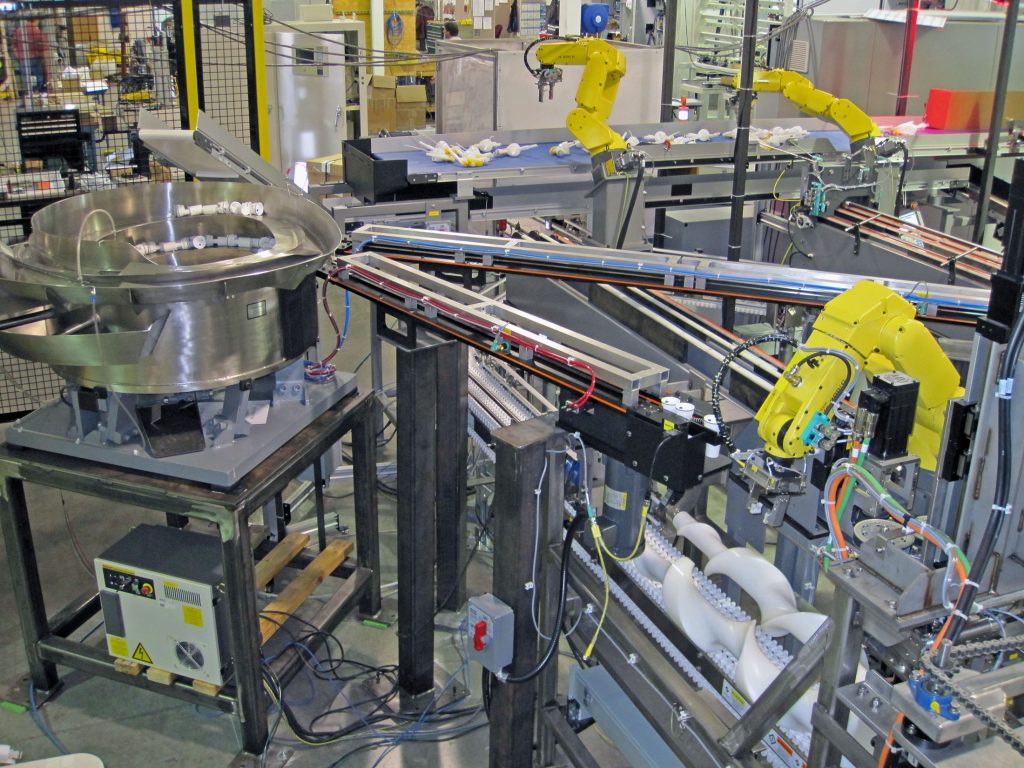

Part assembly automation represents a significant leap forward in manufacturing technology, offering a multitude of benefits that streamline production processes and enhance product quality. At its core, assembly automation involves the strategic integration of advanced technology within assembly processes. This typically includes the use of industrial robot arms, automated guided vehicles (AGVs), vision systems and sensors to manipulate parts for assembly, ensuring precision and efficiency.

Traditionally intricate part assembly was accomplished with manual labor overseas, but with high labor costs, a shortage of dependable workers and businesses’ renewed desire to re-shore manufacturing, automation has become a more viable option. With robotic automation, part assembly can be performed in several operations, such as picking, placing, fastening, inspecting and testing. Additionally, robots can tend machines, such as ovens and presses, by maneuvering a part in and out of them.

The Benefits of Automating Part Assembly

- Increased Efficiency – Automation allows for continuous operation without the fatigue or inconsistency that can affect human workers. This leads to higher throughput and faster production times.

- Improved Quality – Automated systems provide consistent results, reducing the likelihood of errors that can occur with manual assembly. This consistency ensures that each product meets the same high-quality standards.

- Enhanced Safety – By automating potentially hazardous tasks, the risk of injury to human workers is significantly reduced. This not only improves safety but can also lead to lower insurance costs and fewer lost workdays.

- Cost Savings – Although the initial investment in automation technology can be relatively high, the long-term savings in labor costs, reduced waste and increased productivity will result in a favorable return on investment.

- Flexibility – Modern assembly automation systems are designed to be adaptable. They can be reconfigured for different tasks, making it easier for manufacturers to respond to changes in product design or demand.

Industrial Applications for Automating Part Assembly

Many industries are utilizing automation for their part assembly processes. Such as in the automotive industry, assembly automation is used for tasks such as applying adhesives, installing glass and assembling electrical systems. Similar to automotive, the aerospace industry utilizes automation for welding, assembly and material handling to improve manufacturing rates and safety. For industries requiring high precision, such as consumer electronics and semiconductors, automation is ideal for repetitive tasks like assembling small parts or performing processes on a part with speed and accuracy.

Midwest Engineered Systems has extensive experience designing, building, installing and servicing automated part assembly operations optimized for fast and efficient throughput. We have built lines from electronic products to some of the largest industrial assemblies and everything in between. This diversity of clientele allows us to bring innovative solutions that get results for our customers.

Building the future of manufacturing, together

World-class Automation