Logistics & Fulfillment

- Home

- Industries

- Logistics & Fulfillment

Over 30 Years Increasing Efficiency for

Material Handling & Fulfillment Solutions

Looking to increase efficiency in locating and marshaling components and materials within the production environment? Fighting a labor-constricted market? Are orders coming in faster than the human workforce can handle?

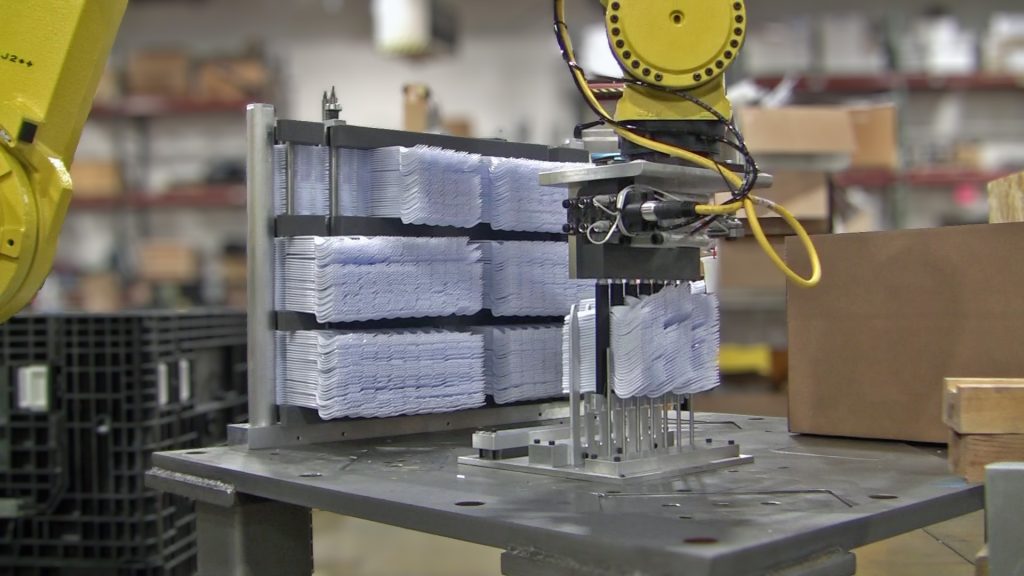

Midwest Engineered Systems provides automated material handling solutions that will keep logistics and fulfillment operations throughput running smoothly for years to come. Robot automation improves efficiency, accuracy, safety and flexibility in all aspects of material handling at warehouses and distribution centers which reduces labor costs, human errors and operational risks in those environments.

By transitioning to robot automation, logistics operations can optimize their processes, increase their productivity, and meet the changing demands of customers and markets. Automation systems can seamlessly integrate with Warehouse Management System (WMS), Warehouse Execution System (WES) and Warehouse Control System (WCS).

Automation Applications

- Palletizing and Depalletizing

- AS/RS Buffer Systems

- Conveyance and Sorting Solutions

- Code Scanning Systems

- AGV and AMR Integration

- Case Packing Operations

logistics Automation expertise

Warehouse, Cold Storage & Distribution Automated Storage Solutions

Packaging & Palletizing Operations

Warehouse & Distribution Center Conveyance

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing