Plasma Cutting

Automating Plasma Cutting for Safety & Precision

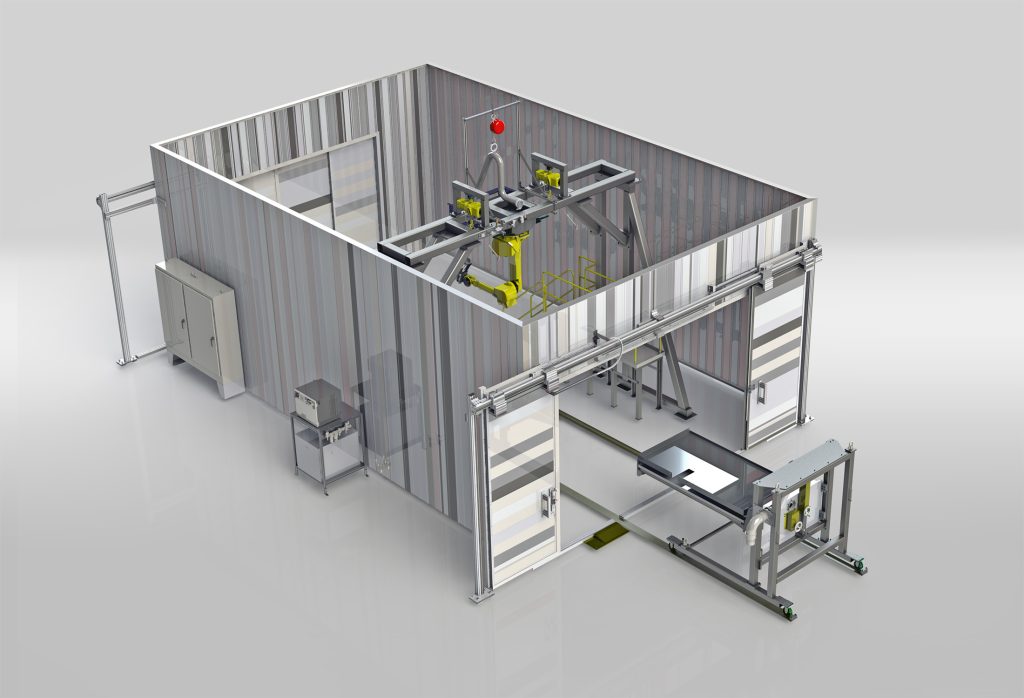

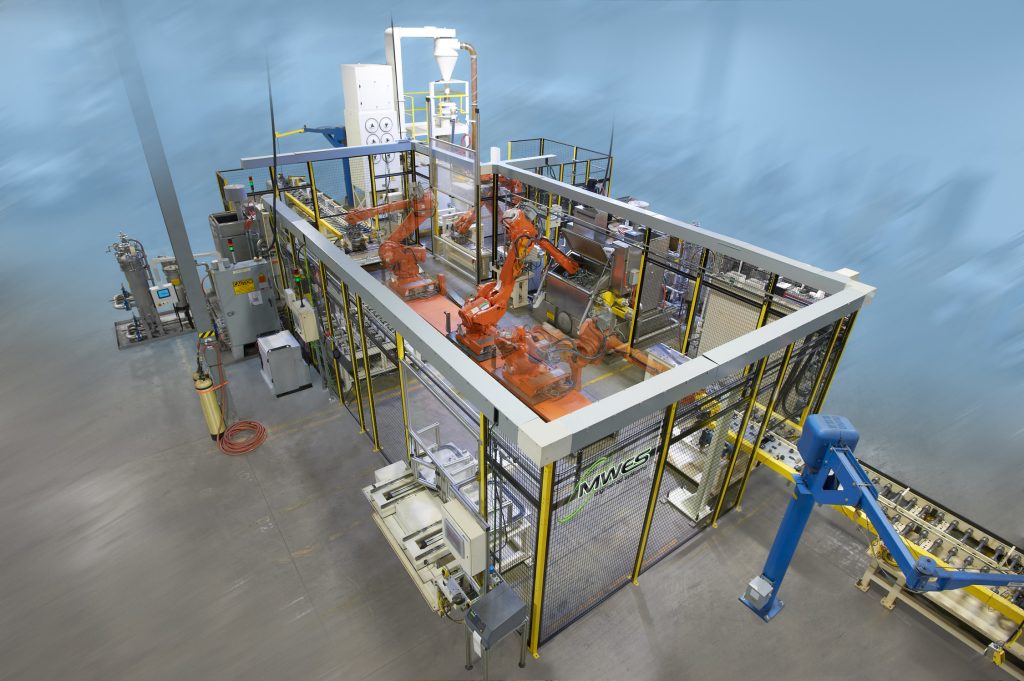

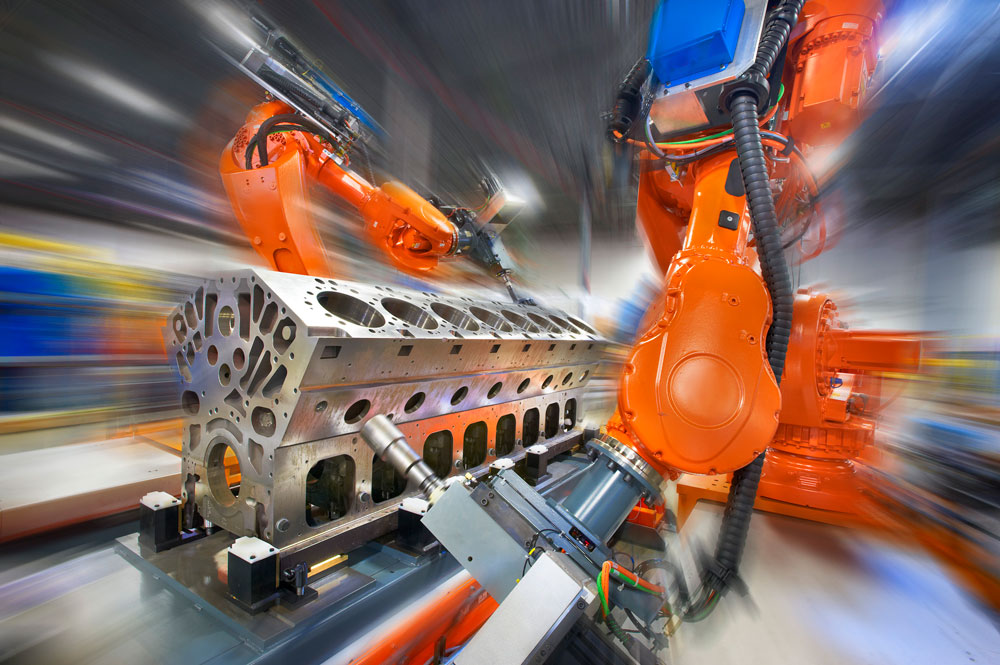

Midwest Engineered Systems has decades of experience integrating modern plasma cutting technology into manufacturing automation systems. This capability allows MWES to reliably mitigate common problems such as attaining proper engraving depth and poor output in both robotic and non-robotic plasma cutting systems. Automated plasma cutters work with various metals, such as steel and aluminum, making them versatile tools in production lines. Advanced plasma cutting software also allows for the management of cutting parameters such as speed, power and gas flow, optimizing the cutting process for different materials and thicknesses.

Automated plasma cutting systems are used in various industries, including automotive, aerospace, shipbuilding and construction. It’s particularly useful for mass production settings where the margin of error has to be minimized and consistency and speed are critical.

Automating plasma cutting operations affords manufacturers a system that can operate continuously with little downtime, significantly increasing throughput. Additionally, by automating the process it reduces the need for manual handling of materials and operation of the cutting equipment, minimizing the risk of worker accidents. Lastly, by eliminating the human element from production, the return on investment (ROI) can be achieved by reduced labor and subsequent insurance costs.

MWES has integrated plasma cutting automation into manufacturing processes. If you are interested in learning more about automated plasma cutting solutions, please contact us today. We can provide you with a customized solution that meets your specific needs and requirements.

Building the future of manufacturing, together

World-class Automation