Heavy Deposition Welding

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Heavy Deposition Welding

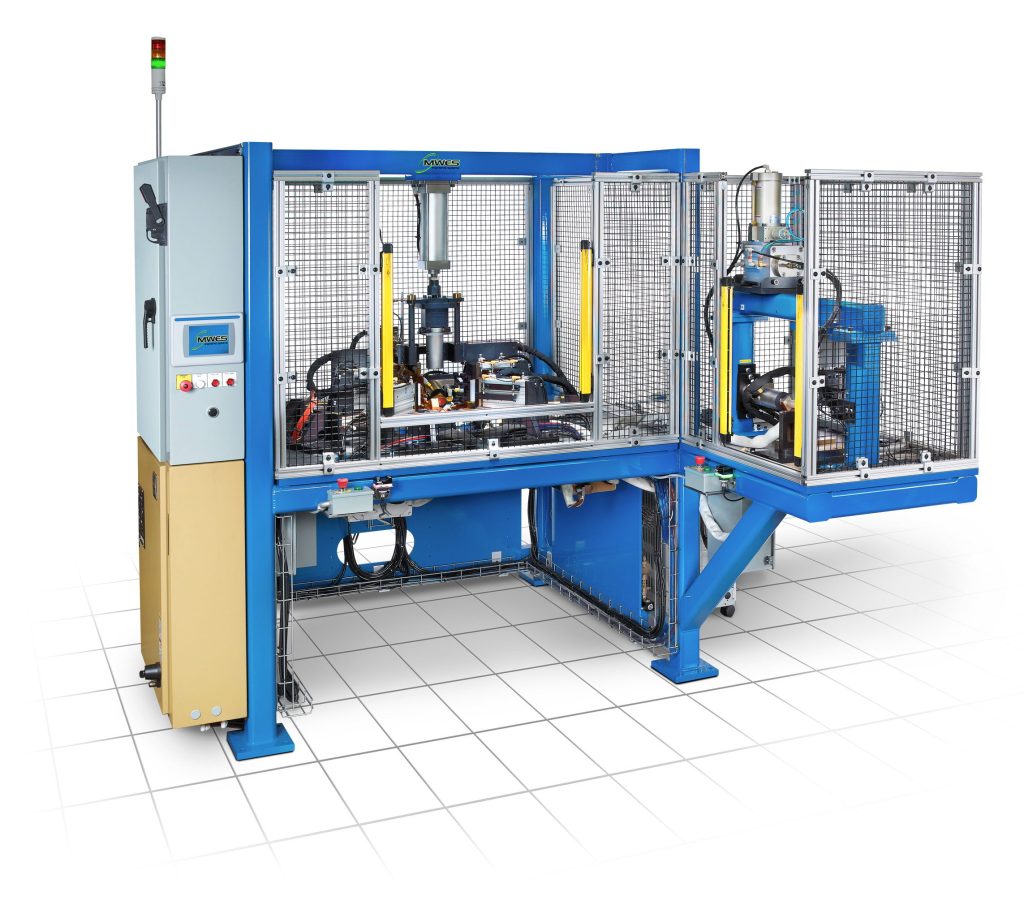

Accelerating Heavy Deposition Welding with Robotics

In the heavy fabrication industry creating welded parts requires welds that have a heavy deposition rate to create stronger components. Making these heavy deposition welds is slow and time-consuming. However, with robotic automation systems using a tandem welding process, heavy weld times can be drastically reduced. Heavy deposition welding applications include industrial-scale agriculture and mining equipment construction and the assembly of heavy steel frames, the production of large weldments, building power generation systems and structural steel assemblies.

Fully automated heavy deposition welding systems for thick and thin-gauge materials come with many benefits. The first benefit is they can reduce production time by using a precise amount of base metals during heavy deposition welding, requiring no composition adjustment of the welding wire. Having to make no adjustments during the automated welding process will decrease production time and ultimately the cost.

Additionally, the heavy deposition process allows industrial factories to very quickly and efficiently produce welded materials at a rate that is not achievable by typical labor standards. Due to the slower speed for heavy deposition welding processes and consistent robotic control, there is an increase in the durability of the welding seam with automated welding systems.

Ultimately, reducing labor numbers will save money in terms of training programs, safety, worker’s compensation and benefits packages as well as the cost of securing skilled workers during labor shortages.

Building the future of manufacturing, together

World-class Automation