Heavy & Light Gauge Welding

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Heavy & Light Gauge Welding

Robotically Automate Heavy & Light Gauge Welding

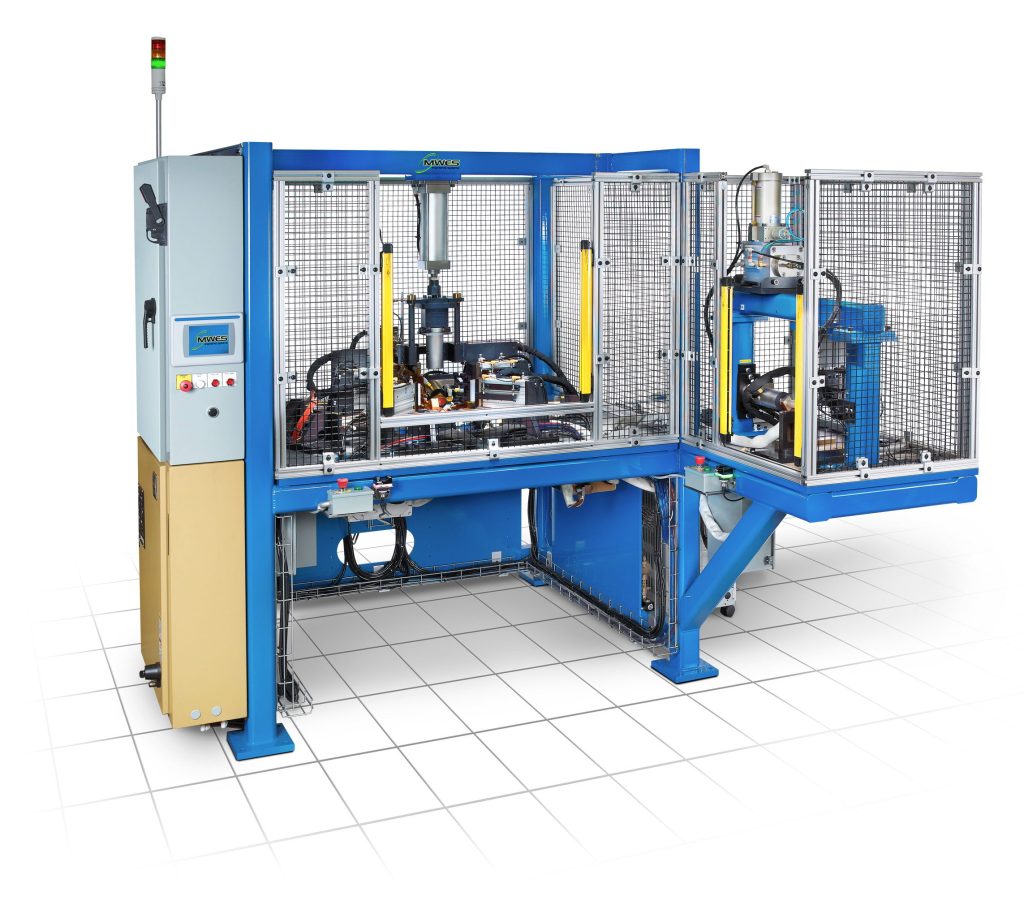

MWES has designed and integrated fully automated robotic welding systems that handle heavy/thick and light/thin gauge materials. Robotic welding operations allow industrial factories to very quickly and efficiently produce welded materials at a rate that is not achievable by typical manual welding standards. Reducing worker numbers saves money regarding training programs, safety, worker’s compensation, and benefits packages and securing skilled workers during labor shortages.

Additionally, there is a precise amount of base metals during heavy gauge welding, requiring no composition adjustment of the welding wire. Having to make no adjustments during the automated welding process decreases production time and cost. Also, due to the slower speed for heavy gauge welding processes and consistent robotic control, there is an increase in the durability of the welding seam with automated welding systems.

Benefits of Heavy Gauge Material Welding

Heavy gauge sheet metal ranges from 25-gauge steel to the thickest gauge, which is known as 7-gauge, or 0.5 in/12.70 mm thick plate. Any metal thicker than 0.5 inches goes beyond the gauge scale and is simply measured in millimeters or inches of thickness – these thicknesses are called ‘plate’ instead of sheet metal.

Demand has increased in recent years for high-strength, heavy-gauge steel. This is particularly the case for large-scale construction projects, such as high-rise buildings, large machinery and container ships. These technologies have been instrumental in the development of very heavy gauge plates such as HBLTM 385 and HBLTM 440 in the field of construction and YP460 in the shipbuilding industry. As the demand for robotic welding of ultra-heavy steel plates increases, automated welding technologies with greater efficiency levels and with high-heat input have been successful at keeping pace.

Applications for Heavy Gauge Robotic Welding

Many industries and manufacturers use robotic integration of heavy gauge welding for their products and assemblies.

- Automotive manufacturers and heavy shipbuilders

- Military hardware and equipment manufacturing

- Steel piping, storage vessels and high-pressure equipment manufacturers

- Oil pipeline component producers

- Agricultural and off-highway construction machinery manufacturers

Benefits of Light Gauge Material Welding

Automated welding processes have advanced to handle a variety of material thicknesses including thin, light gauge materials. Improved welding and sensor technologies allow factories and other facilities to efficiently produce welded components while still accounting for issues such as thermal distortion and part variability across many different industries.

Robotic welding has shown its ability to weld thin-gauge metals, even difficult metals such as austenitic stainless steel and carbon steel efficiently. Thin-gauge materials are considered to be 18-gauge to 0.1875 inches for stainless steel and 24-ga. to 0.1875 inches for carbon steel. Thin-gauge robotic welding is typically done in short-circuit transfer (SCT) mode, as its low heat input is well-suited for thin-gauge welding. Some newer automated robotic systems are capable of pulse-on or pulse-on-short-circuit, both of which can be useful for thin-gauge welding so long as their respective heat inputs are comparable to the input achievable through SCT processes.

Many times, light-gauge robotic welding tends to be performed in a sequence to reduce the overall amount of heat applied to the metal, which minimizes distortion. It’s best to spread out small welds over the joint used in the welding process. The torch angle is another important part of the light-gauge welding process. Generally, the pushing torch angle is used in horizontal, overhead and flat positions to reduce the chances of the process burning through the metal material. For the SCT mode, it is best to utilize a short contact-tip-to-work distance, which is considered to be 0.25 to 0.5 inches Too much contact-tip-to-work distance can lead to increased resistance between the contact tip and the workpiece, causing unstable arcs to develop, MWES’s experienced robotic welding staff has a history of successfully integrating these techniques into robotically automated welding systems.

For SCT welding of carbon steel, its wire diameters can include sizes such as 0.023, 0.030, 0.035, and 0.045 inches In the case of SCT welding of stainless steel, its usual wire diameters are 0.030, 0.035, and 0.045 inches, but will run even smaller for thin-gauge materials.

Applications for Light Gauge Robotic Welding

There are many applications for automated light gauge welding that span different industries.

- Stainless steel food processing equipment for food service kitchens

- Thin wall vent and conduit system construction

- Sanitation devices and medical equipment

- Mobile machinery cabs and guards

MWES has spent decades integrating robotic automation into various welding applications for various industries. If your current welding process is lagging behind others, then contact us today. Our applications engineers can help guide your manufacturing operation to a more profitable and sustainable future.

Building the future of manufacturing, together

World-class Automation