INNOVATION THROUGH AUTOMATION

Integrated Welding

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Integrated Welding

About Integrated Welding

With standard integrated weld systems, the welding automation machinery is designed to specialize in just one of the processes (TIG, MIG/MAG, MMA). They tend to have certain features and functions that allow them to perform their particular process with great efficiency and user-friendliness. High-frequency ignition is a staple of today’s TIG weld systems. MIG/MAG weld systems operate using multiple different settings, allowing for a wide range of adaptability in terms of weld arcs and weld seam dimensions. MMA weld systems optimize high arc stability and ignition characteristics.

About MIG and TIG Arc Welding

The two most common types of gas arc welding are Gas Metal Arc Welding (MIG) and Tungsten Inert Gas Welding (TIG).

MIG Welding

Automated GMAW welding systems can work with aluminum, stainless steel, regular steel and many non-ferrous materials, in thicknesses of 26-gauge, up to and including, large heavy-duty structural components. The simplicity and adaptability of the process make MIG welding a good choice for large, automated industrial operations that require high production rates. Since MIG uses a filler material, it can be used to weld two different materials together, whereas TIG simply fuses the two workpieces together, thus requiring the two pieces to be of the same material.

TIG Welding

This type of welding can be performed vertically or in an overhead position, and requires less complex equipment to operate, whereas TIG welding doesn’t require a spool to feed in. Also, TIG welding can be operated without filler metal in certain applications and can work in a larger range of different metals than MIG welding. Well-programmed automation can keep much more precise and repeatable operations than a human operator, especially at lower speeds.

Previous slide

Next slide

Building the future of manufacturing, together

Where we’ve helped

Our Recent Projects

Aerial Lift Weldments Automation

MWES provided this manufacturer with two robotic welding cells for producing industrial aerial...

Robotic Frame Welding Automation

MWES provided this manufacturer with a robot welding cell that manufactures large generator...

Skid Steer Welding Automation

The robotic weld cell that MWES provided to our customer is capable of processing both Wacker...

Pressure Vessel Head Welding Cell

MWES provided this industrial equipment manufacturer with a robotic welding and positioning...

Concrete Mixer Drum Welding Line

MWES provided this manufacturer with a robotic automation system to weld booster cone sub-assemblies...

Skylift 3-Axis Welding Positioner

This project consists of a MWES standard Robotic Welding Positioner and End Effector for our...

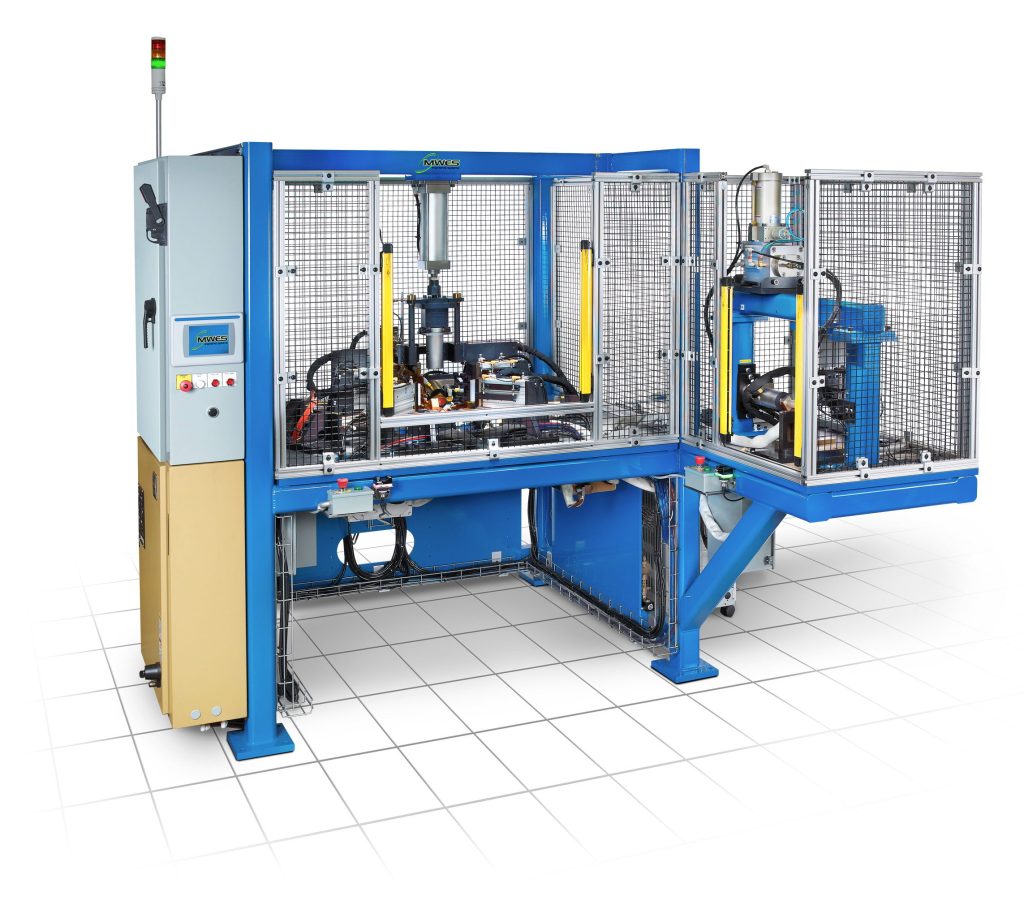

Automated Spot Welding Assembly

MWES built a resistance spot welding automation cell as part of the assembly of automotive...

Tube Cover Automated Welding System

MWES provided this firm with an automated welding machine for manufacturing tube covers for...

3-Phase Transformer Cover Weld Cell

MWES designed and built a completely automated robotic weld cell whose purpose is to complete...