Traceability & Barcode Scanning Automation

- Home

- Industrial Automation Capabilities

- Assembly Automation

- Traceability & Barcode Scanning Automation

Integrate Traceability into Your Production Line with Code Scanning Technologies

Midwest Engineered Systems designs and builds automation systems that take advantage of automated barcode and 2D matrix code scanning systems as part of the manufacturing traceability process. Embedded code reading goes hand-in-hand with complex, fast-moving production and conveyor lines or routing material through entire facilities. Code data can be used to continuously track the progress of work throughout an assembly line.

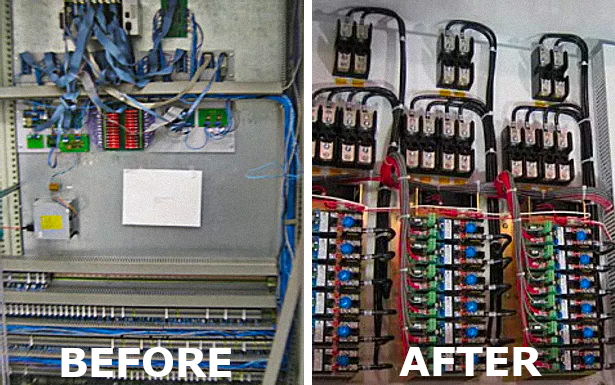

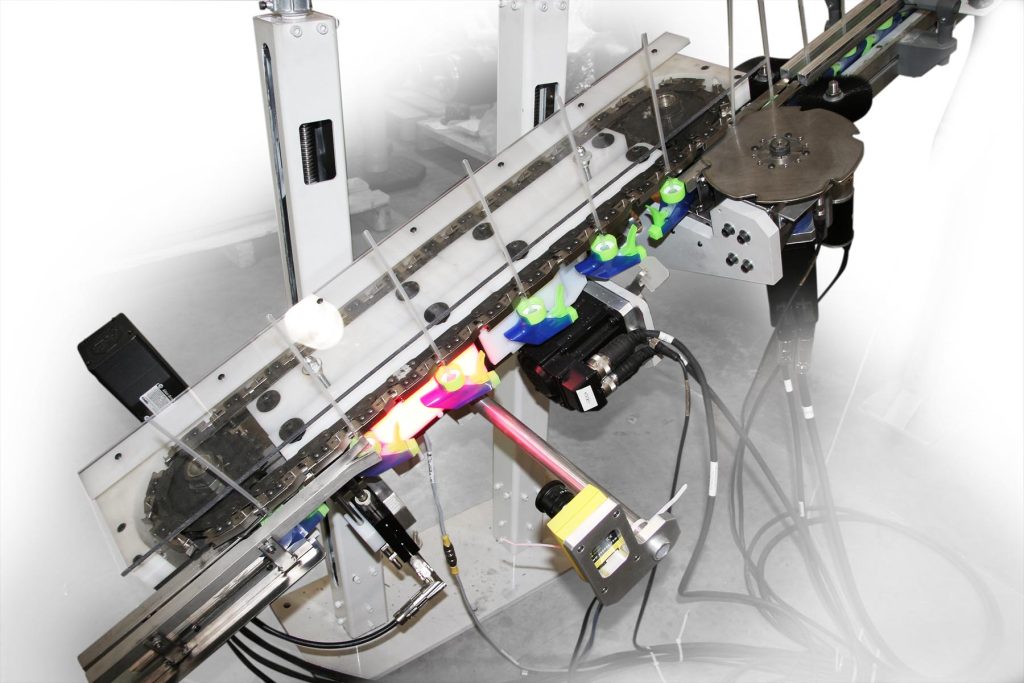

Integrating the 2D matrix and barcode scanning capability into the production automation system eliminates issues found when relying on individuals to manually scan the barcode on every item as it travels through the system. The integration also helps keep the conveyor line moving more efficiently with minimal slowdowns and mistakes. Additionally, 2D matrix scanning be can easily mounted on the EOAT of a robot or simply incorporated into a conveyor system.

Integrating the 2D matrix and barcode scanning capability into the production automation system eliminates issues found when relying on individuals to manually scan the barcode on every item as it travels through the system. The integration also helps keep the conveyor line moving more efficiently with minimal slowdowns and mistakes. Additionally, 2D matrix scanning be can easily mounted on the EOAT of a robot or simply incorporated into a conveyor system.

Automated 2D matrix scanning systems are used by all major distribution and production centers around the globe and are common in assembly lines and pharmaceutical production. Historically this activity had to be done by hand, which is far more prone to mistakes as well as a much slower, labor-intensive process. However, automated vision systems dramatically increase the speed and accuracy at which materials can be processed and sorted automatically without leaving the conveyor system. Barcode and matrix code scanning systems are crucial for traceability not only during the assembly process but also in tracking the part through its lifecycle.

Why Traceability Is Important to Manufacturing

Traceability in automated manufacturing systems is a critical component that ensures the quality and integrity of products throughout the production process. It involves tracking materials, components and finished products from their origin through every stage of the manufacturing cycle. This capability is essential for meeting regulatory compliance, enhancing production efficiency and minimizing risks associated with recalls and liability. Modern traceability systems utilize advanced technologies such as barcodes, 2D matrix codes, RFID tags and real-time data analytics to provide comprehensive oversight. These systems not only track physical items but also monitor production processes, providing valuable insights that lead to improved inventory management, equipment utilization and overall profitability. As manufacturing becomes more complex and globalized, the importance of robust traceability systems grows, ensuring that manufacturers can maintain high standards of quality and safety.

MWES builds and integrates systems that take advantage of the benefits of automated barcode and 2D matrix scanning systems as part of the traceability process. Integrating this technology into production automation systems has provided our customers with faster material routing times and greater production traceability. In many cases, the barcode reading system can be connected to inventory and production control systems to offer even greater visibility to the production process.

If your business is looking to add traceability and automated barcode scanning to a current production line or is considering a new automation installation that captures this advantage, trust MWES to help understand if systems like these benefit your production needs. Contact us today!

Building the future of manufacturing, together

World-class Automation