Medical Cartridge Coating Custom Machine

- Home

- Recent Projects

- Medical Cartridge Coating Custom Machine

Project summary

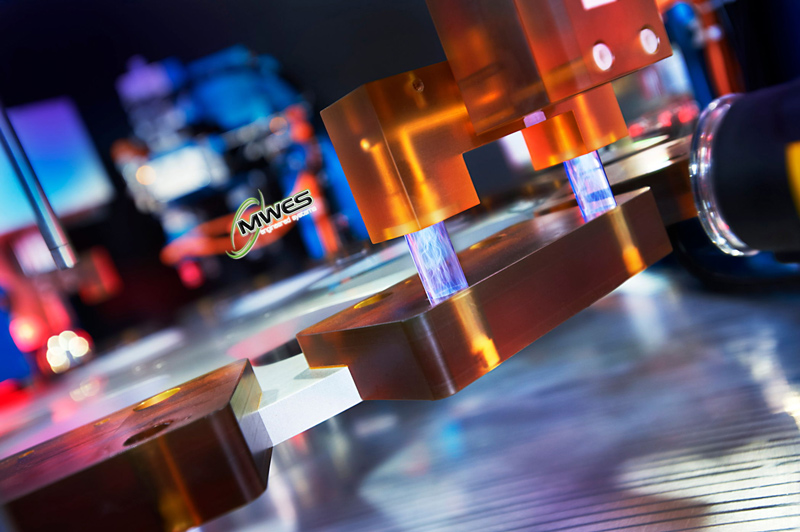

MWES provided a custom medical lab syringe and cartridge coating machine for a start-up medical supplies manufacturing company.

The Challenge

The medical lab industry requires unparalleled precision and reliance that their tools are manufactured consistently. To achieve that level of precision, the human factor needs to be kept out of the process as much as possible. To bring about that level of precision, a medical supplies manufacturer came to MWES with the need to robotically automate their plastic cartridge coating operation.

The firm needed a coating process and automation equipment to meet the performance and demand quantities for their growing customer base and to keep up with the throughput of their competitors. Additionally, the machine had to meet the clean room classification of 100,000 and had to have a cycle time of 12-15 parts per minute.

The Solution

The revolutionary part coating machine MWES produced for our customer offers a superior inert, immobilized lubrication alternative to current lubrication methods including siliconization and grease or oil applications. This machine’s automation equipment features a vibratory bowl feeder, an indexing six-station rotary dial and a vision inspection system. The cartridge coating process includes part ionization, pre-plasma treatment, proprietary coating spray and a post-plasma treatment.

The entire machine is built around the six-station indexing rotary dial. At the first station the operator loads and unloads parts into the station’s part nest. In the second station, the automated pre-plasma treatment head comes down into position and treats the inside surface of the parts. Once complete, the head retracts and the dial indexes to the third station. Here the part is pneumatically gripped and raised to the lubricant dispenser where the coating is applied to the parts.

After the coating has been applied the dial indexes to the fourth station, where sensors verify that the parts are still present in the nest and the vision inspection system checks the coating quality of the parts. The dial indexes to the fifth station where a post-plasma treatment is performed on the parts to ensure that the lubrication properties are within the desired parameters. The dial indexes to the sixth and final station, where a reject chute dumps parts that did not pass the vision systems coating quality inspection.

The automated coating machine included these features and processes:

- Bowl Feeder – A vibratory bowl feeder automatically orientates the parts and feeds the parts to the assembly machine.

- Dial Assembly – A six-station servo indexing rotary dial system with part nesting moves the parts through the coating process.

- Ionizers – Ionizers are used to blow off any dust particles and reduce the parts’ static electricity before the coating process.

- Pre-Plasma Treatment – The parts needed to be treated with a gas plasma both before and after the coating is applied. This process uses a unique downstream plasma process that operates at atmospheric pressure to enable high throughput. The pre-plasma treatment increases the surface tension of the area where the coating is going to be applied for better adhesion characteristics.

- Post-Plasma Treatment – The post-plasma treatment finalizes the coating process to provide the excellent lubrication properties needed for the product application.

- Coating Spray – The coating is sprayed with a positive displacement pumping system. This allows for very precise and repeatable amounts of the coating onto the product.

- Vision System – A proprietary vision system is used to inspect the coating after it has been applied to the product. It can measure the uniformity and dispersion of the coating to verify the consistency of the process.

- Process Testing and Install – All equipment was set up in the MWES facility for production trial runs and testing before installation. Final runoff testing was conducted at the customer’s site to ensure the system meets all the requirements.

Impact to the Customer

The finished solution for the custom syringe and cartridge coating machine achieved many benefits for our customer. The machine MWES provided met the quantity demands of their growing customer base, provided a superior performing product in the marketplace, and quality assurance of their product is based on the repeatability of the manufacturing process.

Midwest Engineered Systems has a wide range of experience in building machines for use in the medical industry. If you’re looking to improve your medical products manufacturing throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today.

“Working with MWES helped us transition this new patented coating process from a lab scale to a high throughput production scale. This was the first full-scale TriboGlide production machine that integrated all the process steps including the QC camera inspection and fully automated parts handling. MWES did a great job with first understanding our technology and then help design the process flow. Overall we are quite satisfied with the outcome that has enabled us to scale-up this new process for coating of pharmaceutical containers.”

Vinay Sakhrani, Vice-President of Technology at TriboFilm Research Inc.

Innovation Through Automation

Client Details

TriboFilm Research Inc. – A manufacturer of medical supplies and equipment.