Automated Cheese Cubing Machine

- Home

- Recent Projects

- Automated Cheese Cubing Machine

Project summary

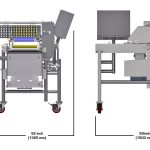

MWES provided a leading cheese producer with several new automated cheese cubing machines to keep up with their manufacturing throughput.

The Challenge

A leading national cheese supplier had existing machines for cutting 0.625 to 1.50-inch slabs of cheese into cubes and required additional machines to handle an increase in demand. However, this firm was unable to acquire new machines from the original equipment manufacturer since they were no longer in business. Therefore Midwest Engineered Systems was contracted to produce similar automated machines while incorporating several quality-of-life design improvements into the design.

The Solution

MWES provided our customer with several new automated cheese cubing machines that met all food safety standards, including complete machine assembly and electrical control integration. All the potential food surface areas were constructed and finished to current USDA and WDA standards, using all food-grade materials. Our manufacturing practices met with National Electrical Codes (NEC) to ensure safety and were evaluated by WDA for cleanliness. Lastly, a complete pre-shipment test was performed at MWES’ facility to ensure that all systems were designed, configured and built to the customer’s satisfaction before being shipped to the customer’s site. This includes hardware checkout and configuration, verified communications and installed and tested software applications.

We began by analyzing their existing machines and that design was re-engineered to incorporate improvements based on the customer’s experience to improve uptime and minimize wear. The new equipment includes a control system with full PLC logic capability and an operator interface with motor speed controllers. The machines would receive large slabs of preformed cheese on an infeed conveyor. As the slab passes through the cutting station, horizontal and vertical slicing blades stamp out the slab into equally sized cubes.

Impact to the Customer

Our customer benefited from a number of enhancements to their food manufacturing line. Such as higher end-product quality, flexibility for future expansion, increased production rates, reduced maintenance downtime and minimized potential wear and tear on the machines.

Midwest Engineered Systems has a wide range of experience in building food-handling automation systems. If you’re looking to improve your food handling throughput, we have the knowledge and experience to make the project a success.

Contact us to learn about how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A leading national cheese supplier based in Wisconsin.