Standard Machine Tending Capabilities

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- Robotic Machine Tending

- Standard Machine Tending Capabilities

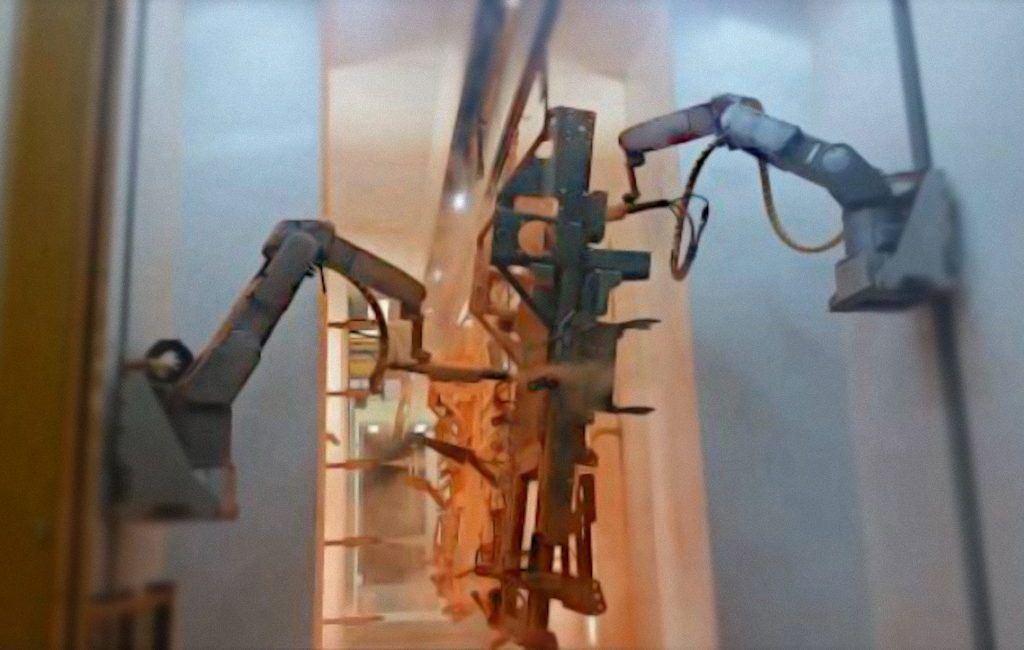

Move past the part rack with MWES’ robotic machine tending systems

There are many machine tending systems on the market today. Why should you choose our solution over the others? One word: flexibility.

Midwest Engineered Systems takes machine tending to the next level by utilizing advanced technology to further reduce labor and increase flexibility. The MWES standalone, drop-in system is ideal for manufacturing settings that see a high mix of components with varying levels of inter-part commonality. This comes from the system’s ability to operate without relying on custom presentation racks and technician-developed programming for every new part style introduced. Removing reliance on both saves costs by reducing the need to purchase expensive fixturing, as well as retaining a dedicated robot programmer to update the system.

Midwest Engineered Systems takes machine tending to the next level by utilizing advanced technology to further reduce labor and increase flexibility. The MWES standalone, drop-in system is ideal for manufacturing settings that see a high mix of components with varying levels of inter-part commonality. This comes from the system’s ability to operate without relying on custom presentation racks and technician-developed programming for every new part style introduced. Removing reliance on both saves costs by reducing the need to purchase expensive fixturing, as well as retaining a dedicated robot programmer to update the system.

The advanced MWES cells are designed to bring the true promise of automated machine tending to production facilities, by reducing the need for workers to fill part racks for presentation to the machine. The machine tending cells are also designed to offer value-added operations that can sidestep resetting machines or require operator intervention to do simple, off-machine tasks. Both of these features allow employees to tend more valuable operations while increasing efficiency.

Contact us to learn more about the MWES machine tending system and how it can help increase your facility’s throughput.

Building the future of manufacturing, together

World-class Automation