Robotic Painting System Retrofit

- Home

- Recent Projects

- Robotic Painting System Retrofit

Project summary

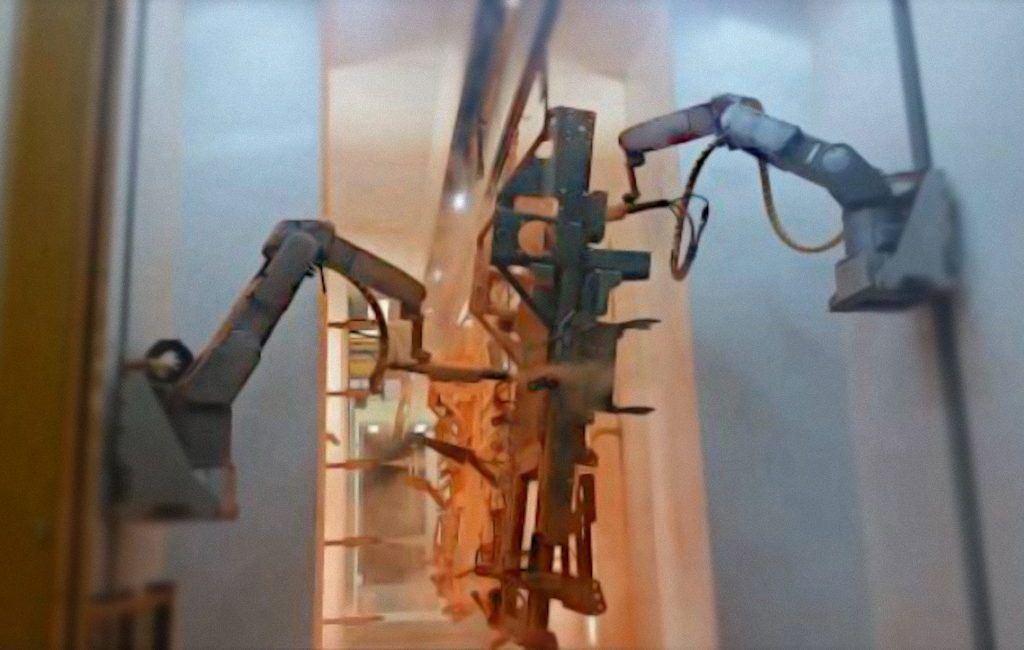

MWES retrofitted and upgraded a robotic painting system to replace an existing manual painting operation.

The Challenge

A consistent manual painting operation can be a strain on a manual workforce. Not only is the work potentially hazardous to the workers but acquiring enough workers to perform the operation has been a challenge for many businesses and industries. With robotic automation, many of these formerly manual labor-centric jobs can be done with robots. For that reason, a firm that deals in metalwork sought out Midwest Engineered Systems to field retrofit four robotic paint systems onto an existing powder coating line in order to eliminate an existing manual painting operation.

The Solution

Midwest Engineered Systems provided this firm with a robotic system that featured four Fanuc Paint Mate 200iA/5L robots each with a Gema GA02 Automatic Powder Coating Gun. The robots were each mounted on a MWES vertical servo lift allowing them to reach parts that filled the entire 892 mm height of the spray booth. Adding the robot lift allowed for a very compact robotic automation solution, without massive investments in custom automated production systems or larger robots. These four robots and lifts were retrofitted to the existing powder coating line and were integrated into the existing control system and paint booth housing. This system also featured light curtains and a safety control system for the robot cells.

Impact to the Customer

By switching to robotic automation, this firm saved itself from an otherwise tight labor market. Furthermore, robotic automation provides this firm’s painting operation with greater efficiency and more consistent results.

Midwest Engineered Systems has a wide range of experience in building robotic painting automation systems. If you’re looking to improve your painting throughput, we have the knowledge and experience to make the project a success.

Contact us to learn about how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A firm that specializes in metalwork based in Wisconsin.