How MWES Case Packing Systems Work

- Home

- Industrial Automation Capabilities

- Material Handling Automation

- Case Packing Systems

- How MWES Case Packing Systems Work

Advanced Technology to Make Things Easy

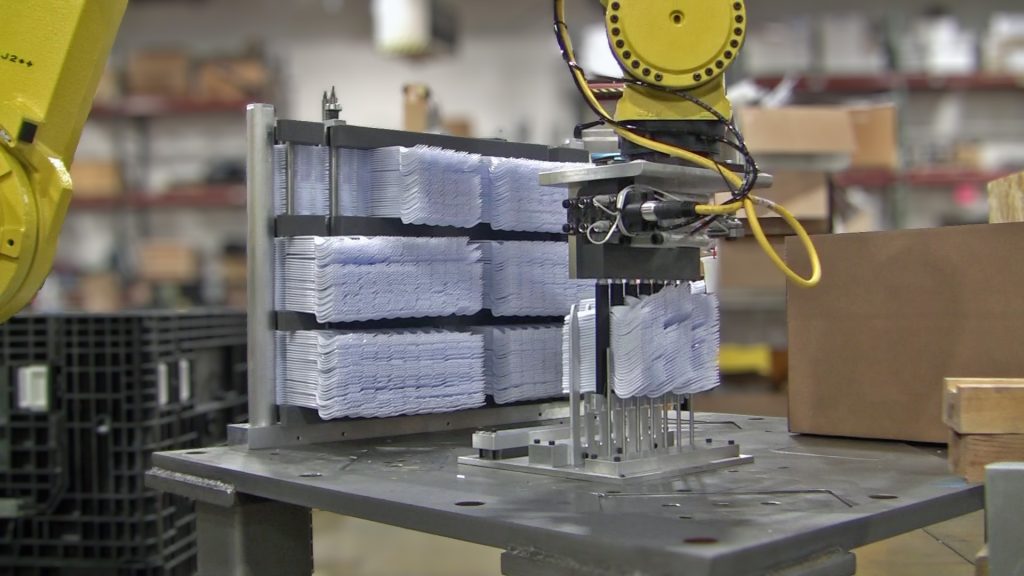

Bags of product enter the system from a customer-supplied conveyor, a photo eye sensor (or for more complex packaging, a vision system) determines the product’s position. This information is sent to the robotic system that will track the package as it moves into the machine. Once in position, the robot will pick up the bags using purpose-designed vacuum cups that can be dialed into specific weights of the product, ensuring proper holding strength while reducing product damage.

The robots deposit the product bags into previously erected boxes on the system’s included outfeed conveyor following the pack patterns outlined by the customer. The system will continue to fill the shipping boxes in the specified pattern until the boxes are deemed full. Having a vision system integrated into the production automation system allows for more complex box-filling patterns that offer the most efficient box volume usage.

On their way out of the system, the shipping boxes are metered before moving onto either a box-closing system the customer may already have or a hand-closing process. The MWES case packing system makes it easier to add further automation including box erectors upstream of the robotic case packer as well as palletizing systems downstream when the customer is ready to take the next step in packaging automation.

While this is just an overview of how the MWES case packing system operates with some of the more standard options involved, learn more about how the system works, what options are available and what performance can be had. Contact us today.

Building the future of manufacturing, together

World-class Automation