Standard Palletizer Cell

Drop-in Robotic Palletizing Automation for Increased Performance

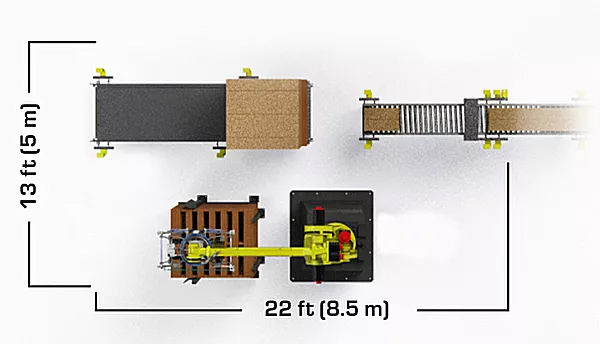

Midwest Engineered System’s drop-in case palletizer systems are designed to automate a production line’s palletizing operations as quickly as possible. Our standard system offers everything that’s needed to get you up and running, including automated infeed, outfeed and pallet picking all controlled by an easy-to-use touchscreen controller.

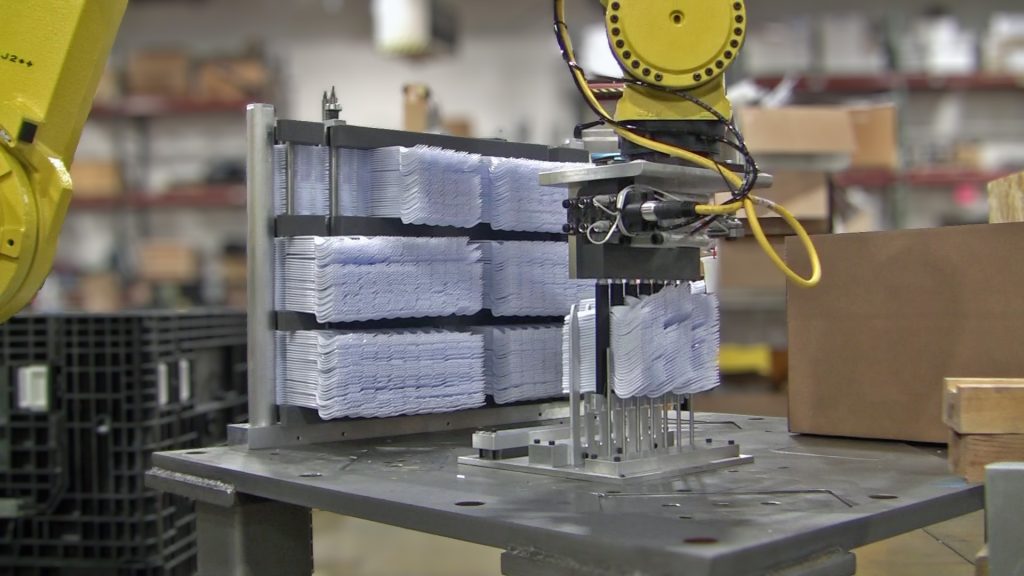

While the focused, single SKU operation of the system is designed for increased throughput without the need for dedicated personnel, the palletizer can work on many packaging types including sealed cases, trays and bliss-style containers that can be top-picked with vacuum end-of-arm tooling (EOAT). Using pre-made recipes, the system can be set up to switch between SKUs and box types directly on the cell’s HMI.

If more throughput is needed, the MWES systems can be augmented with accessory systems including a second infeed to handle more than one production line with the same robot. Operations can be added to the layering process and beyond including automatic slip-sheeting between layers, multiple pre-programmed layer formats or other specialized options.

THe Base System Components

Designed for dependability, the MWES standard palletizer systems are built with widely available, industry-leading components.

- Allen Bradley PLC with 10in PanelView HMI

- FANUC M410iB/140H industrial robotic arm

- Motorized case infeed roller conveyor with reference pusher for proper positioning

- Automated outfeed conveyor for finished pallets

- Vacuum pad gripper end-of-arm tooling

- Robot-based automatic pallet picking

- Safety fence guarding including light curtain at the pallet exit location

Palletizer Specifications & Performance

The MWES turnkey case packer cells can be designed to work with a wide variety of packaging sizes.

- Case size range: 9-29 inches long, 5-21 inches wide and 3-24 inches high

- Max case weight: 50 lbs

- Max case rate: 15 CPM

- Max pallet height: 90 inches (including the pallet)

Have an application that lies outside this system's abilities?

At Midwest Engineered Systems we know that not all palletizing operations can use off-the-shelf systems. Packaging can take up a variety of dimensions and palletizing may also need specialized operations. If your packaging process requires more than a standard system can provide, contact MWES today. We can engineer a bespoke solution that can automate even the most demanding palletizing operations.

Building the future of manufacturing, together

World-class Automation