AS/RS System Performance

- Home

- Industrial Automation Capabilities

- Material Handling Automation

- AS/RS Buffer Systems

- AS/RS System Performance

Automated Enhanced Workflow with Performance

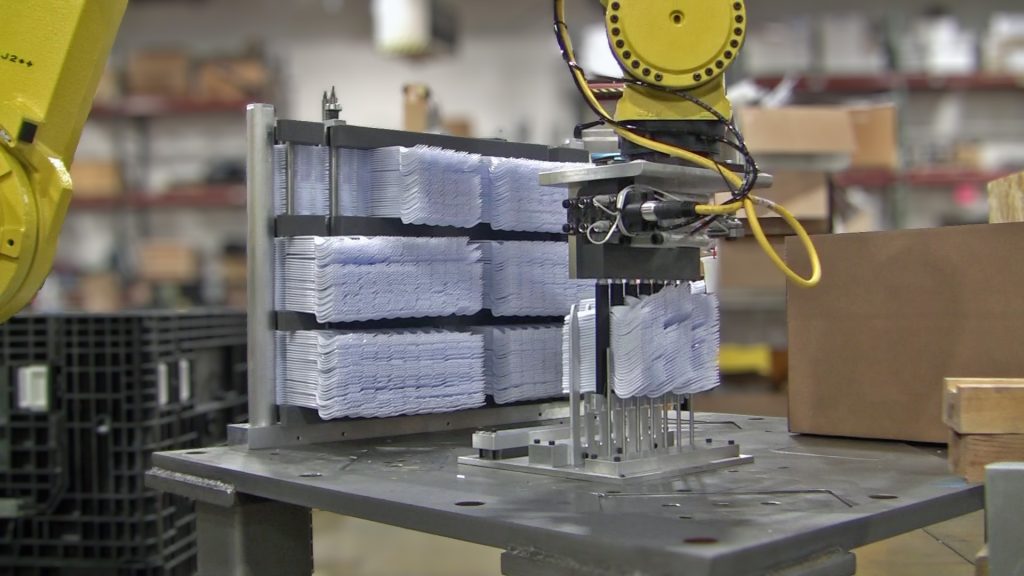

The benefits of the MWES Automatic Storage and Retrieval System (AS/RS) buffer system do not stop with what happens on the production floor. Material arrival and removal data can be harvested for production performance analysis. It allows a production manager the ability to see beyond individual machine performance and understand the logistics that feed into a machine or process performance. This accountability can be monitored to determine production efficiencies and identify bottlenecks hidden between processes.

Adding remote signaling capabilities, manufacturing stages can not only alert the system when a process is nearing completion, but they can also request the materials for the next job – all without leaving the cell. The AS/RS system can retrieve materials and tools as the completed work is returned to storage and return to stock the recently arrived finished parts without needing human help. This ability helps keep production efficiency high by streamlining the logistics and reducing potential downtime waiting for parts.

Taking advantage of all these aspects makes the MWES AS/RS buffer system much more of a trusted workflow manager that has the potential to better see the entire manufacturing process as a singular system, not just a collection of unconnected machines and resources. The system’s benefits provide the opportunity for a forward-thinking production facility to move to the next level of efficiency and productivity.

Building the future of manufacturing, together

World-class Automation