AS/RS System Components

- Home

- Industrial Automation Capabilities

- Material Handling Automation

- AS/RS Buffer Systems

- AS/RS System Components

The Components of the AS/RS Buffer System

The Automatic Storage and Retrieval System (AS/RS) buffer system comprises four major components: the pallet racking, the shuttle, the infeed/outfeed and the control system. All aspects of the system are designed to be deployed within pre-existing production facilities.

The MWES AS/RS Buffer System is designed to fit within existing production facilities using a modular, scalable approach that not only allows installation flexibility, it also provides the ability to be easily expanded in the future.

The Pallet Racking

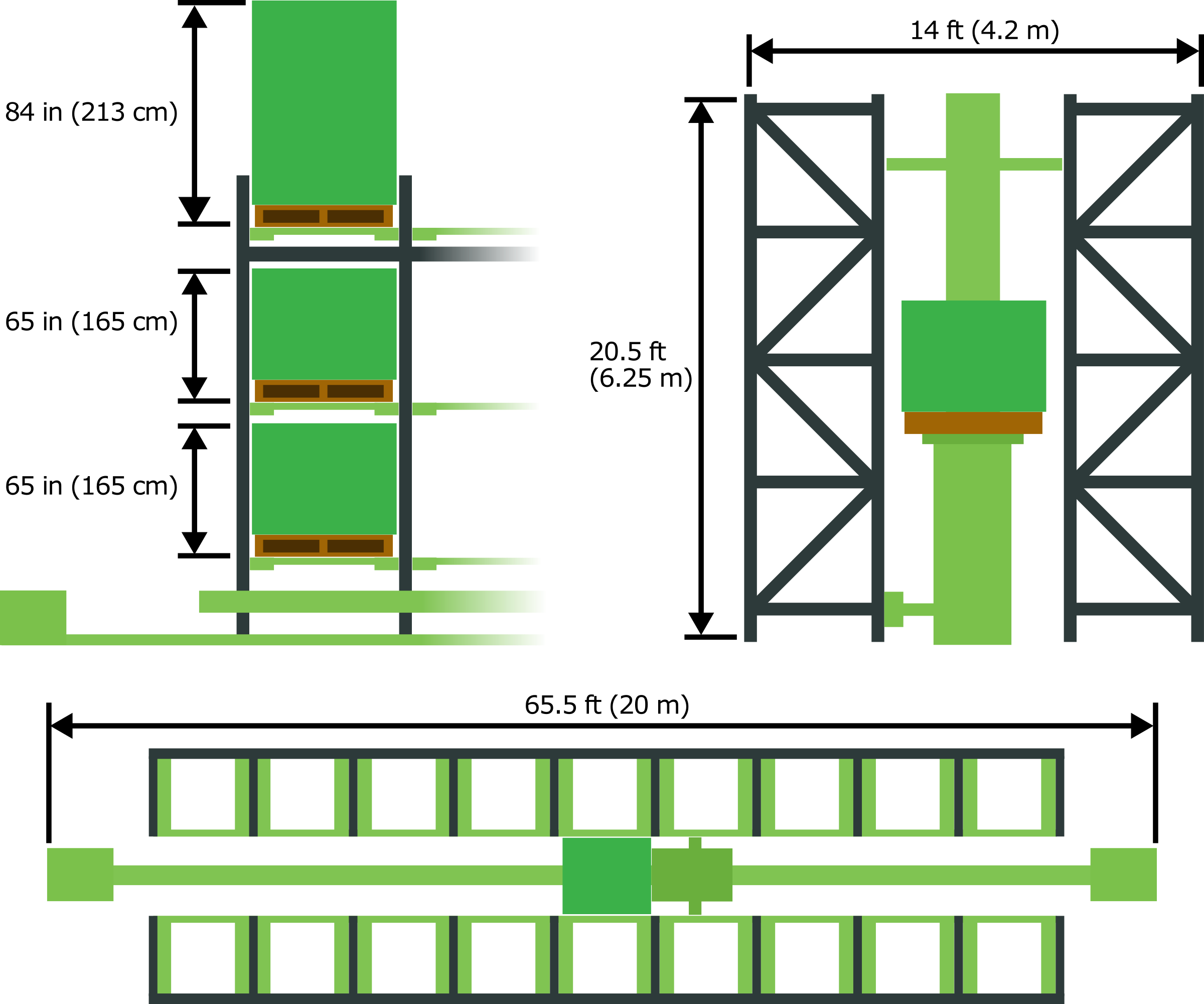

The storage shelving is comprised of standardized, easily extensible racking that’s been modified to operate with the AS/RS system. These racks allow material heights of 65 inches (165 cm) on the lower racks with a maximum height of 84 inches (213 cm) on the uncovered top racks delivered on standard pallets.

Racks can be installed with only a few vertical shelves to installations that extend up to 30 feet tall. The racking can also be added both horizontally and vertically (up to 30 feet) at a later date, should the need arise.

The Pallet Racking with Shuttle Dimensions

The Infeed & Outfeed

Getting materials into and out of the AS/RS system can be accomplished with several infeed and outfeed configurations, from automated conveyor lines to simple locations where a forklift can deliver a pallet. The infeed/outfeed can be integrated into an existing conveyor or other transfer process configuration.

The Shuttle

The shuttle is responsible for moving materials in and out of the system as well as retrieving and storing these materials in the racking. It travels on a ground-mounted track under servo power to the positions necessary. The shuttle’s dimensions are noticeably more compact than similar fork trucks, allowing the entire system to take up less overall square footage.

The Control System

The electronic control system is the brain of the system. Operated through a touchscreen interface, the control system provides easy-to-use access to the system. An operator uses the provided HMI to summon materials from the system or command the system to store pallets for use later. The rest of the operation is automated, including selecting available storage locations to physically move the pallets or materials.

The control system can be extended to report on materials movements to production management software and even be used in advanced stages to be commanded by such systems if the customer requires it.

Being fully automatic in operation removes the potential for human injury in the process as well as the most efficient operation possible. Removing the operator from the storage process is also instrumental in saving floor space.

Of course, humans will be humans and the AS/RS system is ready for occasions when things don’t go to plan or warnings are ignored. The shuttle system includes built-in OSHA-approved light curtain sensors that identify material or people in its path. If the curtain is breached at a distance, the machine reduces its speed to a quarter of its ability. Should the violator close the distance, the system will shut down all movement until the curtain is again clear.

Building the future of manufacturing, together

World-class Automation