Material Handling Automation

- Home

- Industrial Automation Capabilities

- Material Handling Automation

Bringing process together with

Material Handling Automation Systems

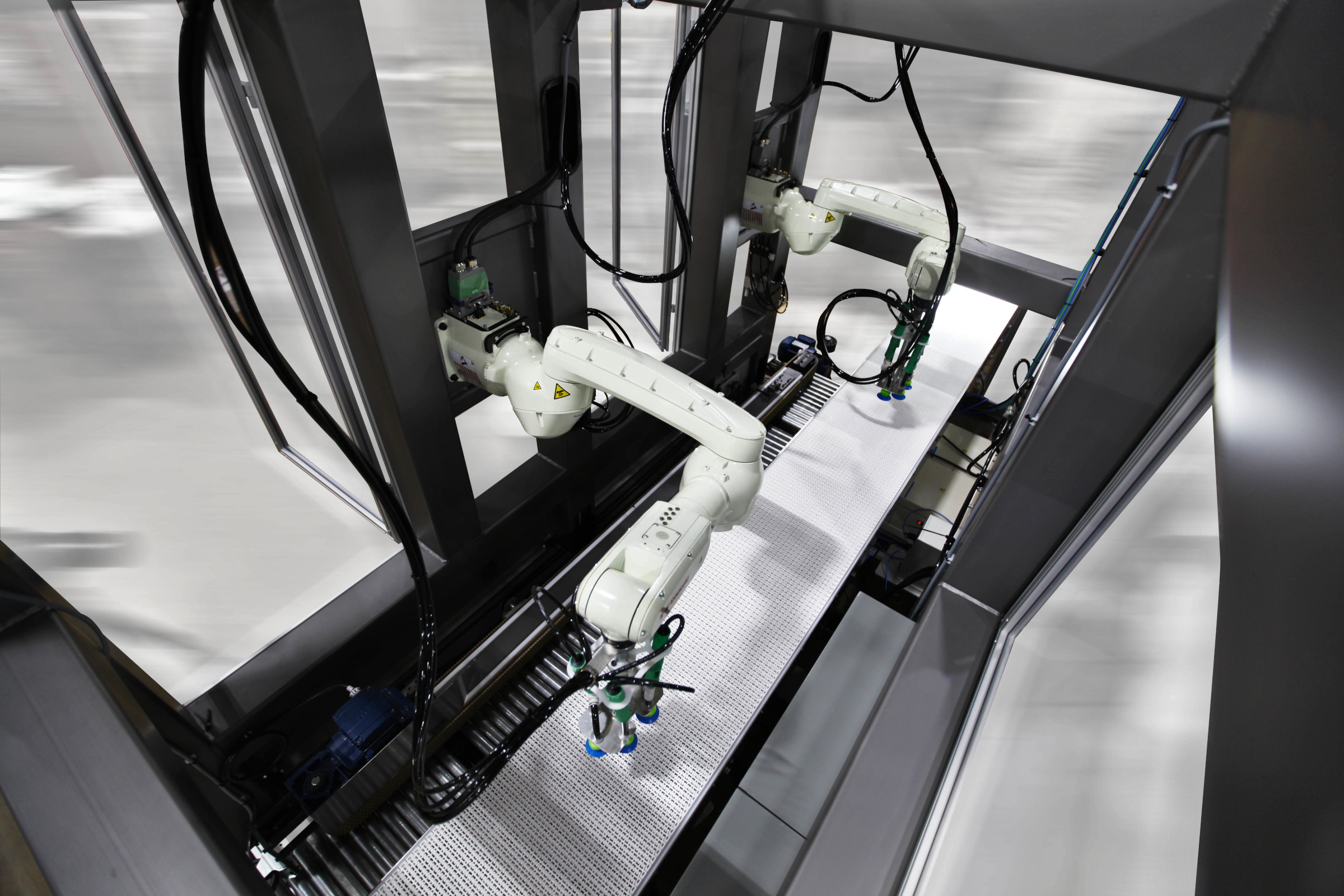

Let Robots Run Your Material Handling Operations

From the end of the production line to the edge of the dock, MWES can take your material handling processes to the next level, with fast and efficient material handling automation solutions that increase throughput and reduce reliance on hard-to-staff positions.

Robotic material handling is the future of manufacturing, logistics, e-commerce, and other sectors. It is a smart and reliable solution that can improve the quality and efficiency of various processes and operations. Robotic material handling is better than manual labor in many aspects, and it is here to stay. Material handling automation is not only beneficial for businesses but also for society and the environment. By using robots, businesses can improve their competitiveness and profitability, while creating new opportunities and jobs for humans. By reducing human exposure to dangerous or repetitive tasks, robots can enhance human health and well-being. By minimizing waste and emissions, robots can contribute to environmental sustainability.

For more than 30 years MWES has designed and integrated automation systems that produce tangible results. No matter the industry, our dedicated staff of engineers is adept at understanding specialized and diverse processes from a variety of industries, to deliver systems that are designed to solve the unique problems every customer encounters. MWES can be relied upon to provide a professional material handling system installation in any industry while providing a substantial return on investment (ROI).

Features of Automated Material Handling

Building the future of manufacturing, together

The Areas where we can Help