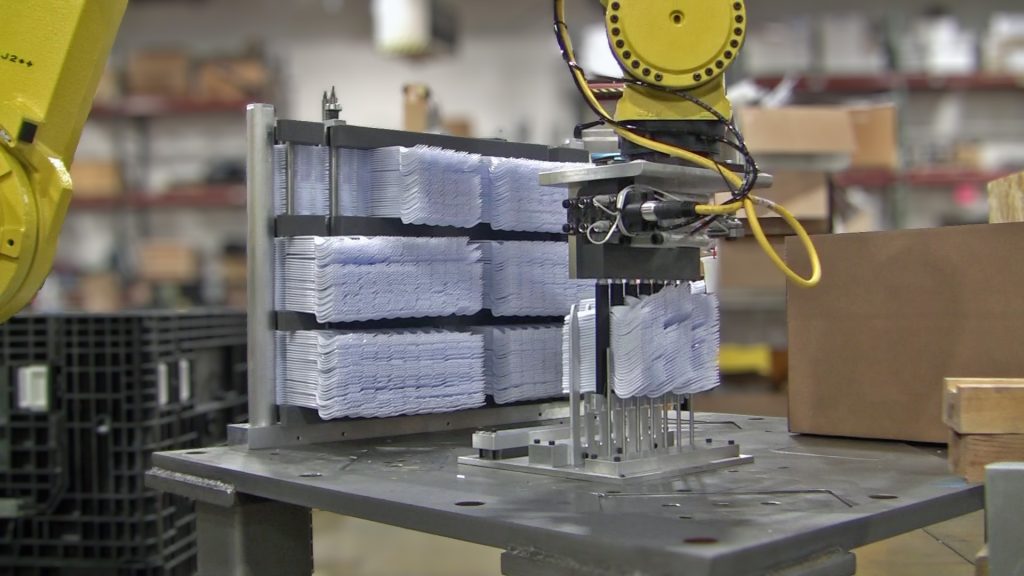

AS/RS System Features

The Key Features of the AS/RS Buffer System

Floor space is a hot commodity in today’s production settings. It also can be one of the biggest determinants of how productive a facility can be. The movement of materials and the storage of components and fixtures can be a puzzle that easily soaks up that valuable square footage if not solved properly.

But getting more control over your materials and inventory doesn’t have to be difficult. MWES has worked hard to develop a system that’s as easy to install and upgrade as it is to operate. Below, we’ve broken out some of the more innovative aspects of the system.

Ease of Operation

MWES storage systems can be operated from a touch panel on the shop floor. With a minimum of training, the easy-to-use screen design allows workers to quickly call for materials or tooling by touching through the interface. Through the same panel, workers can also add new items to the inventory and connect the materials to current or new jobs.

Safe to Use

Our system uses OSHA-approved light curtain technology to stop potentially dangerous situations from happening. When a worker begins to move close enough to the machine, it automatically slows its operation. If the worker continues to breach the area, the machine will immediately stop its operation and turn on warning lights. The system will not move until the workers have removed themselves to a safe distance from the system. This helps ensure the workforce stays safe throughout its operation, even when they haven’t been specifically trained on the hardware.

Made for production environments

Sometimes there just isn’t enough room inside production facilities to store materials, tooling, or work in progress. Conventional automated storage and retrieval systems would require the acquisition of another building to house the system – one purpose-built just for the storage system. The requirements tend to drive the integration of AS/RS systems to sums that make it prohibitive for many firms whose automated storage needs aren’t as tied to high storage volumes or pick speed.

Storage capacity can be added as needs arise

Want to start with a two-shelf system but would like the option to add another level later on? Started with 20 linear feet of shelving but now needs to double that capacity. Thinking of putting a second system in the outbuilding but want both systems to integrate? All of these options are what the MWES AS/RS system was designed to provide right from the start. The MWES production AS/RS system was developed to make it easy to increase its capabilities – within pre-existing production facilities. Not only is it easy to start with a smaller system to prove its benefits, but it allows expansion without tearing the system out to put a new one in.

No specialized containers or pallets required

Most large automated storage and retrieval systems work from custom-sized cartons and bins to make the system work. Not only is there investment in the structure and the kinetics of the system, but there’s also quite a bit of investment that goes into these specialized containers. Not so with the MWES AS/RS system. We’ve built our system to operate on standard pallets used throughout the world to ship and move products and materials. If it works with your current forklift, it should work with our storage system. And for large items, they may not even need to be placed on a pallet.

Building the future of manufacturing, together

World-class Automation