Welding Fixtures

- Home

- Industrial Automation Capabilities

- Robotic Welding Systems

- Welding Fixtures

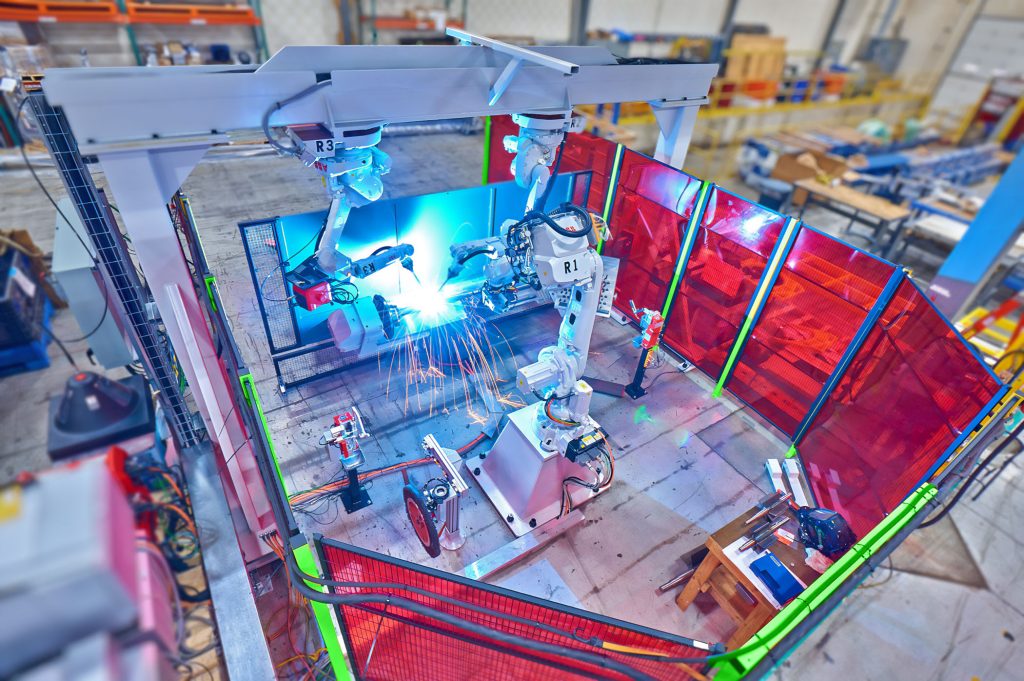

No Welding Automation is Complete without Welding Fixturing

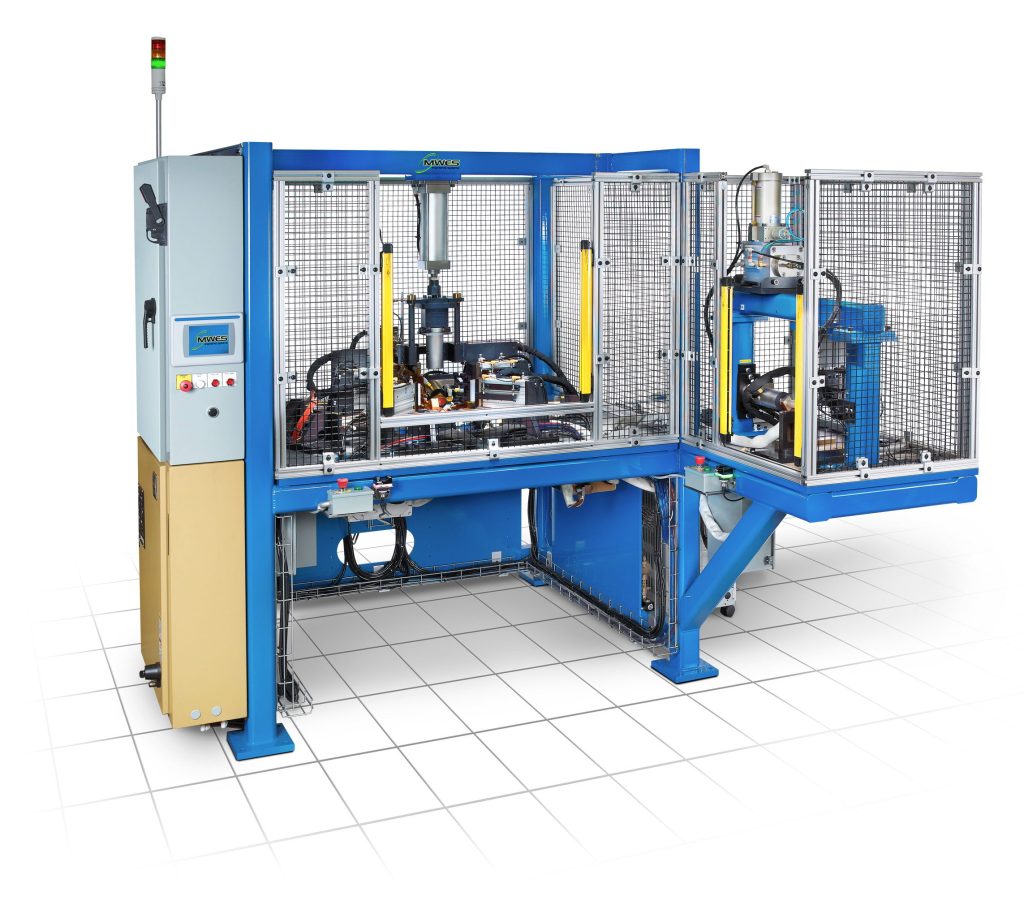

One of the most important keys to success in designing and building automated robotic welding systems is the ability to properly hold pre-tacked assemblies or capture multiple components for welding. Additionally, the infinite variety of possibilities for a weldment’s shape, size and weight requires unique, custom-engineered fixturing solutions for each application. Midwest Engineered Systems engineering capabilities give us the ability to design robust fixtures for welding automation projects regardless of the complexity and deliver a turn-key production line integrated solution.

Automated welding fixtures do more than just secure and position the workpiece, they can handle workpieces to a predetermined acceptable tolerance and work within precise system dimensions. Welding fixtures make it easier to rapidly perform welding operations on parts with consistently high standards of quality for the entire welding process. By using automated weld fixtures, the overall production costs can be lowered and the work environment be made safer for the system operator.

Utilizing weld fixtures allows machines to take on physically demanding, hazardous and repetitive tasks. Industrial robotic systems can go beyond human limitations in terms of load-bearing, speed, precision, endurance, size of materials and strict adherence to a set of task directives. There are several ways welding fixtures can be controlled in an automation system including hydraulically, with pneumatics as well as the more common servo drive systems. Weld fixtures are ideal when welding large steel trusses, structural framing, large cylinder assembly, and steel framing for data center servers.

Hydraulic Welding Fixtures

Pneumatic Welding Fixtures

Manual Welding Fixtures

Our highly experienced engineering team understands the benefits and drawbacks of each type of welding fixture and utilizes their extensive knowledge base to determine the best control technology for the automated weld fixtures we integrate into new automation systems. If your welding process is transitioning over to robotic automation then welding fixtures are a necessity. Contact us today and speak with one of our applications engineers and they can help guide you through the process.

Building the future of manufacturing, together

World-class Automation