Cylindrical Robots

- Home

- Types of Industrial Robots

- Cylindrical Robots

Robots Designed for a Small Space

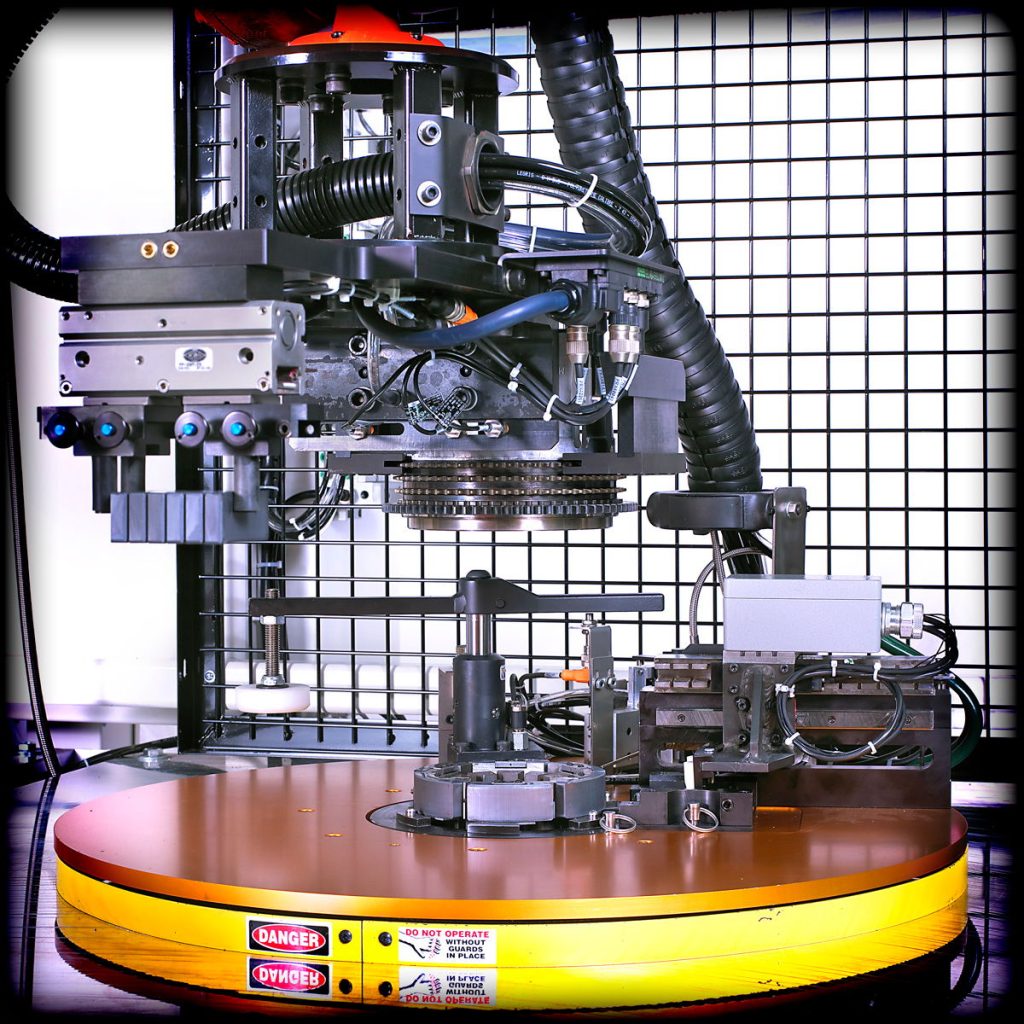

As a differentiator to conventional industrial robotic arms, Cylindrical Robots have a primary arm that moves up and down rather than pivoting on a series of axes. Built within the robotic arm is a cylinder that creates this motion by extending and retracting itself. In many of these cylindrical robotic models, the rotation is generated by gears and a motor, and the vertical motion is generated using a pneumatic cylinder.

Cylindrical Robots use a coordinate system, with three dimensions that use a selected reference axis and relative distances from it, for specifying point positions. Point positions are also specified by using the distance to a selected reference direction and the axis’ relative direction, and by the distance to the axis perpendicular to a selected reference plane.

These types of robots are useful for objects that need to have rotational symmetry around their longitudinal axes, such as a metal cylinder for heat distribution, long, straight wires that produce electromagnetic fields, and the rounded cross-sections of straight pipes. Cylindrical Robots also tend to be quite fast, although this speed leads to rotational inertia issues that could impact repeatability if the system isn’t configured within the scope of its abilities.

Applications of cylindrical robots

- Spot welding automation

- Robotic casting and molding machine handling

- General machine handling applications

- Material handling applications including package assembly and palletizing

- Robotic coating and finishing applications

- Automated assembly operations

While there are several distinct situations where cylindrical robots are optimal for automation performance, many processes can be done with other, more common robot types like Cartesian or SCARA robots. These other robot types can go a long way to matching the speed and precision seen in cylindrical robots.

If you’re considering automating a process where cylindrical robots might be used or looking for service or replacement of a current robotic system, contact Midwest Engineered Systems. We have decades of experience with a variety of robot types and configurations in all manner of applications. Our application engineers can work with you to develop robotic processes that increase throughput while providing the quality necessary to make the production automation project a success.

Building the future of manufacturing, together

World-class Automation