Automated Tailstock Boring Machine

- Home

- Recent Projects

- Automated Tailstock Boring Machine

Project summary

MWES provided a construction equipment manufacturer with an automated steel crane strap milling, boring and finishing machine.

The Challenge

Working with large, thick steel beams is a challenging task that demands specialized equipment to bore and mill holes into them. A company commissioned MWES to construct an automated machine that could bore, mill, and finish two holes into the tailstocks of 10 to 40 feet long industrial steel crane straps.

The Solution

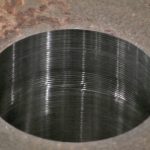

MWES provided our customer with a 4-axis vertical machining center mounted on a motorized controlled moveable carriage. The 13.5-meter long motorized slide consists of a machine tool-grade carriage capable of automatically positioning the tailstock for the 10, 18, 20 and 40 foot long straps. The station is designed for high feed milling, rough boring and then finishing operations to produce two holes in the tailstock between 2 and 10 inches.

To start, the operator loads the appropriate fixtures for the crane straps onto the box-way carriage weldment. Then uses an overhead crane to lower the strap into the fixture and clamp the strap in place using the bar knobs. The operator then installs the cutting tool into the machining head and enters the strap part number into the CNC controller which starts the machine once the operator has cleared the cell.

The through-the-tool chip evacuation air valve opens, and the spindle indexes into the strap with the cutting tool this helps dissipate the steel chips during the cutting and milling operation. Once the finishing process is complete, the operator unclamps the crane straps and hoists them out of the cell using an overhead crane. The operator then sweeps away the loose steel chips in preparation for the next cycle.

Impact to the Customer

The automated steel boring machine that MWES provided our customer with a precise and consistent method for producing holes in the tailstock of crane straps.

Midwest Engineered Systems has a wide range of experience in building material removal and drilling machines for the construction industry. If you’re looking to improve your manufacturing automation throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

An industrial construction equipment manufacturer based in Manitowoc, WI.