Our Process

- Home

- Our Process

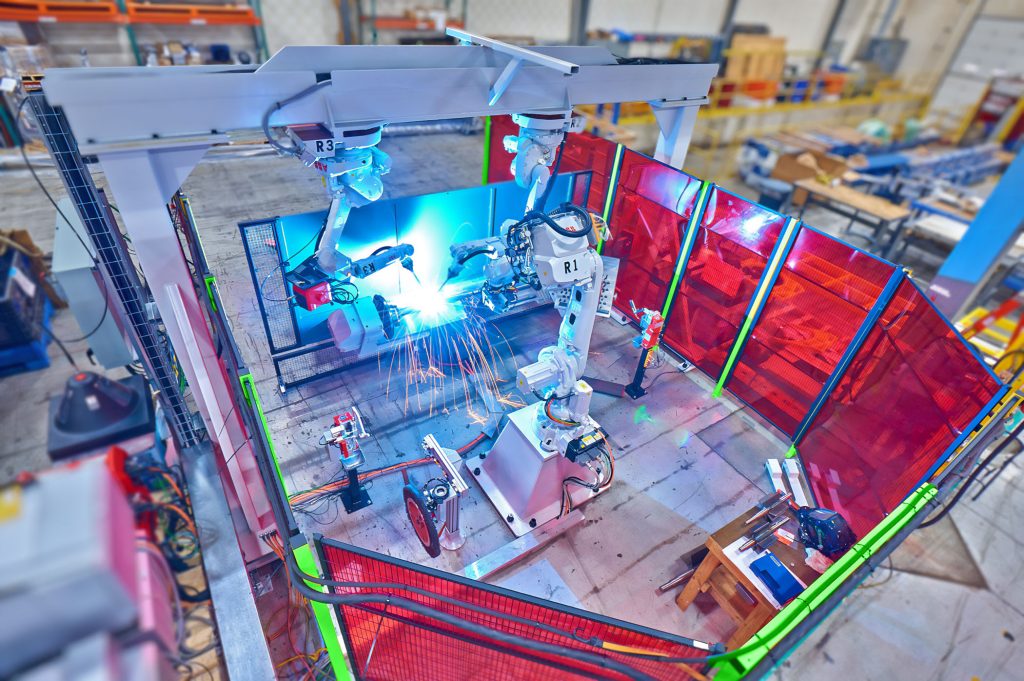

Bringing process together with

MWES' Project Management

With each automation project, Midwest Engineered Systems implements a project management process that walks through the steps for successful equipment integration. The process describes the procedures that are taken to manage every element of the project.

The diagram above outlines the process MWES employs when engaging in a project with our customers. If you would like to learn more about how our process works please reach out to one of our sales engineers for more information.

Building the future of manufacturing, together

How we can help your business with

The MWES Process

Our Process

With each automation project, Midwest Engineered Systems implements a project management process that walks through the steps for successful equipment integration.

Process Development

Our approach to automation process development is to first evaluate the firm’s current production operation and understand the company’s process needs.

Proof of Principle Testing

We offer the ability to experience the performance of an automation system with real parts and production conditions before significant investment in a production automation system is made.

Consolidating Multi-Line Production

We can utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution.

Engineering for Manufacturability

We can help reduce the costs associated with automation by analyzing and suggesting product and process modifications.

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing