Blog & News

Check out the latest from MWES

Categories

The Evolution of Industrial Automated Control Systems

In the realm of industrial manufacturing, the rise of industrial automated control systems has been nothing short of revolutionary. These systems, which encompass a broad range of hardware and software, are designed to enhance automation efficiency, precision and reliability in various industrial processes. Without them, the automation we take for

Visit Us at the Converters Expo 2024

Members of the Midwest Engineered Systems web handling division will be attending this year’s Converters Expo at Lambeau Field in Green Bay, WI. The expo runs from April 17-18 and we will be at booth #425 in the Atrium. Once there you can speak with our experts on web handling and

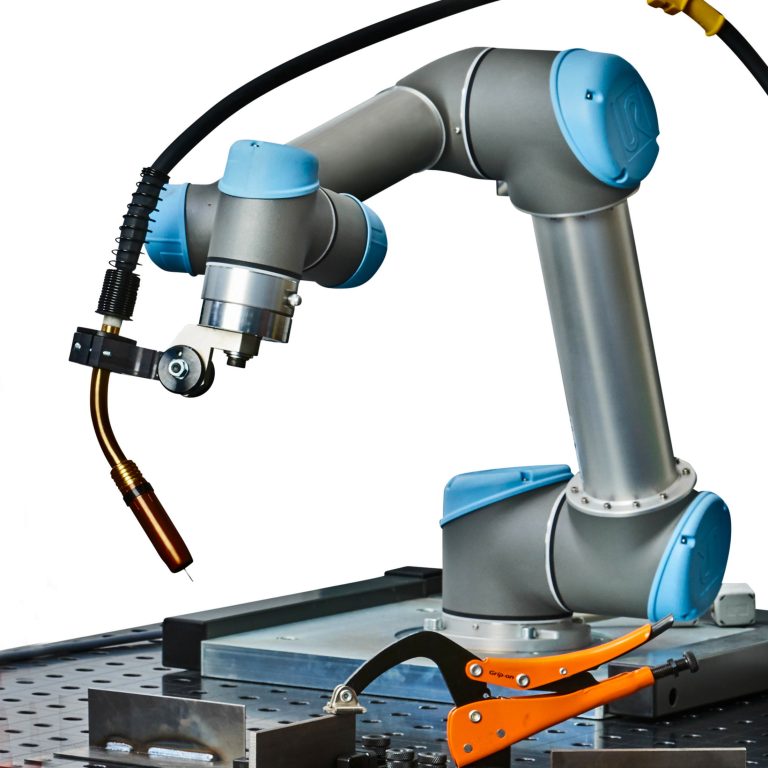

Embracing Automation: Mitigating Risks in the Transition from a Manual to a Robotic Workforce

Global manufacturing stands on the brink of a transformative leap – the shift from a volatile manual labor workforce to a fully automated robotic process. This transition brings about increased efficiency, productivity and long-term cost savings. However, it does carry with it a host of risks that need to be

How Robotic Automation is Revolutionizing Medical Laboratories

As the recent pandemic showed the world, not properly running a cleanroom laboratory can not only endanger the lab workers but the greater world as a whole. Medical laboratories are essential for conducting scientific research, developing new drugs and diagnosing diseases. However, many of the tasks involved in these processes

MWES Receives Two Fanuc Integrator Sales Awards in 2023

Building upon their illustrious track record, Midwest Engineered Systems (MWES), a respected industry leader in the most innovative automation sector, is the latest recipient of the prestigious FANUC 2023 Authorized System Integrator Sales Award for both the 35+ units and the Growth Award. MWES’s 33 years of trusted experience are

AGVs vs AMRs: What’s the difference and which one is right for you?

If you are looking for a way to automate your material handling and transportation tasks, you might have come across two acronyms: AGV and AMR. But what do they mean and how do they differ? Midwest Engineered Systems has decades of experience integrating robots into manufacturing production lines. With that

Get a Federal Tax Break on Automation Equipment with Section 179

If you are the owner of a small to medium-sized business looking for ways to reduce your tax liability and increase your productivity, you may want to consider investing in industrial robotic automation. Robotic automation in itself can help your business save time, money, and resources over time while improving

Cobots: The Innovative Solution to Labor Shortages

In today’s fast-paced industrial landscape, labor shortages have become a critical challenge for many businesses. The struggle to find and retain skilled workers has led companies to seek alternative solutions to maintain productivity and competitiveness. Enter collaborative robots, commonly known as cobots. These advanced robotic systems are not only addressing

Join us at the ICEC in Orlando

Midwest Engineered Systems will attend the 2024 International Converting Exhibition and Conference (ICEC) at the Orange County Convention Center in Orlando, Florida. This conference runs January 9-11 and we will be exhibiting at booth #1333. This conference is an amazing opportunity to speak with our web handling and converting experts.

How Lights-Out Manufacturing is the Future of Manufacturing

Lights-out manufacturing is not a fantasy, but a reality that is becoming more common in the manufacturing sector. It requires the support of various technologies, such as machine learning, cloud data, machine vision and robotics. These technologies allow machines to communicate with each other, monitor the production process and perform