Bottle & Trigger Assembly Line

- Home

- Recent Projects

- Bottle & Trigger Assembly Line

Project summary

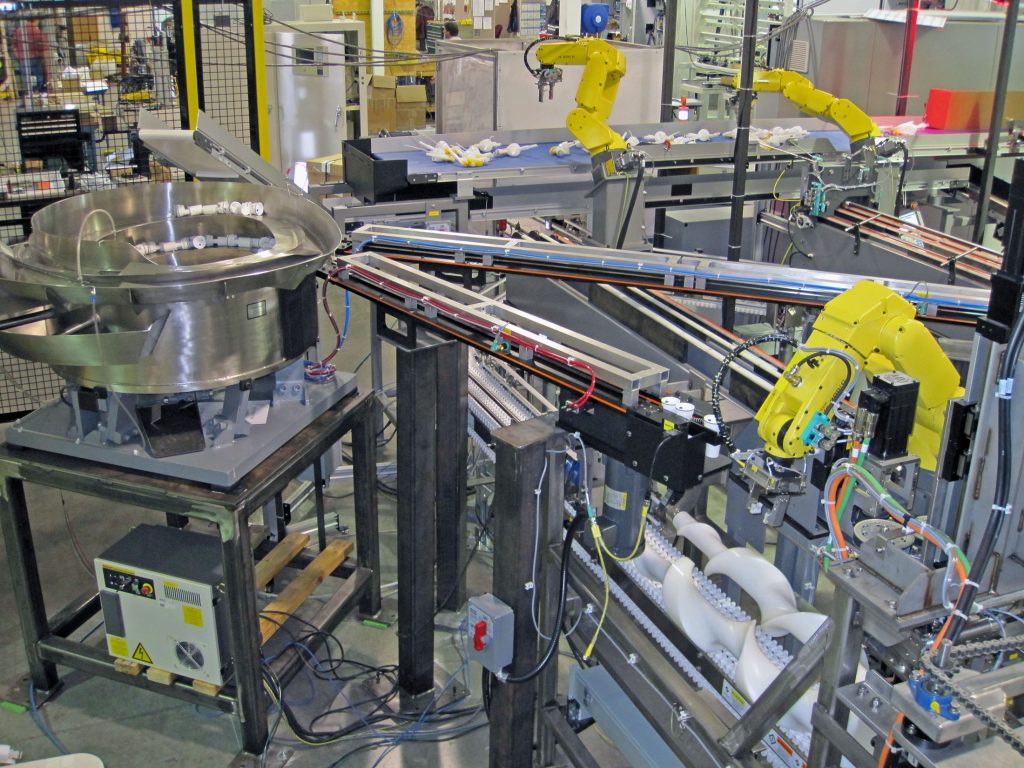

MWES provided a cleaning supplies manufacturer with a robotically automated assembly line to cap and assemble sprayer bottles.

The Challenge

This firm had to cap spray bottles on a manual assembly line which required a large number of workers to operate. With a shortage of manual labor and the high costs associated with labor, this firm turned to MWES to work out an automated solution. The system had to retrieve loose bottle sprayer tops from a conveyor line and attach them to the bottles.

The Solution

MWES provided our customer with a trigger and bottle assembly system that received filled bottles, sorted and located triggers from a conveyor line for assembly, and torqued triggers to bottles within customer-defined specifications. Additionally, the system ultrasonically welds the triggers to the bottles to ensure a tight grip. The system utilized multiple robots, Linmot linear actuators, custom conveyors and dual servo feed-screw controls.

Loose spray bottle caps arrive into the system by conveyor where two robots equipped with grippers and vision systems pick and place individual caps into the part positioner and inline conveyor. On a second conveyor, loose full bottles are brought into the system. Next, a third robot picks the caps from the inline conveyor and places the caps into the cap and bottle marriage assembly conveyor.

Once the cap is attached to the bottle the assembly indexes down a conveyor where a dual servo feed-screw twists the top securing it to the bottle. Lastly, an ultrasonic welder is utilized at the point where the cap and bottle unite to provide an extra layer of security.

Impact to the Customer

The robot automation system MWES provided our customer greatly improved their throughput and production speed to one part every five seconds. The final system allowed part assembly, part verification, tracking for trigger closure torque, 100% verification of all parts and efficient error recognition.

Midwest Engineered Systems has a wide range of experience in building robotically automated assembly lines. If you’re looking to improve your assembly throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A leading manufacturer of industrial cleaning supplies based in Racine, WI.