Industrial Control Systems

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- Industrial Control Systems

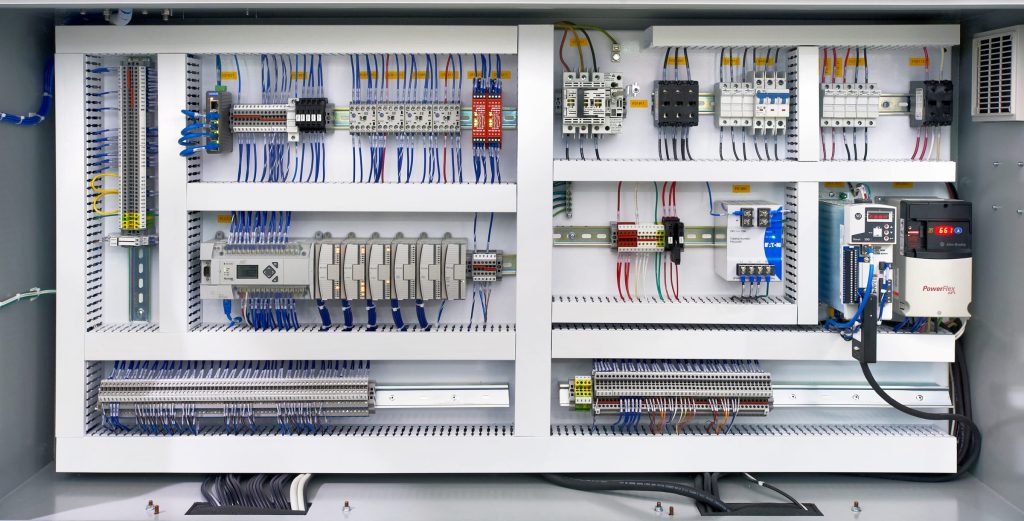

Industrial Automation is Nothing Without Finely Tuned Control Systems

Midwest Engineered System’s high-performance automation solutions make connecting your machines, data and people simple. MWES industrial control systems provide greater flexibility, increased productivity, less risk and lower costs by visualizing and running processes with state-of-the-art operator interfaces, keeping critical systems up and running, and leveraging the latest functional and process safety systems.

As an automated production line integrator, MWES understands the industrial sector’s need for high-quality, effective automation control systems is becoming increasingly apparent. The right industrial automation control systems can create new paths for organizations to grow and become more interconnected.

The goal of industrial control systems (ICS) in automation is to integrate functions and processes between industrial machines, equipment and devices within manufacturing plants. With automation control systems, repetitive tasks can be easily handled while other resources are used to optimize industrial production-level processes. This capability will cover repetitive tasks such as the creation and maintenance of batch information records, batch changeovers, the creation of schedules for periodic machine maintenance and many other tasks.

Automation control systems can also be used to streamline the process of scaling a plant’s production up or down or to ease the process of incorporating new products into a plant’s production line. Whether the automation control system is a robotic, manufacturing machine or assembly line system, there are many ways to make each of those systems more efficient and profitable through better automation control systems.

Advanced communication and data transmission for industrial automation control systems depends on smart devices, sensors on equipment and data security measures. These automated actions could allow the plant’s production levels to be scaled automatically based on the most up-to-date collected distribution channels and sales information. Another example would be machines moving from one batch to the next batch without interruption.

Benefits of Automation Control Systems

There are a number of benefits for organizations when they integrate automation control systems into their manufacturing plants.

- Greater accuracy – Larger amounts of data can be collected. This can lead to extensive gains in terms of both individual product and batch traceability.

- Integration – Automation control systems can create greater cohesion between the plant and supply chains, research and development, sales, compliance processes and other business sectors within an organization.

- Resource efficiency – With fewer resources needed for tracing industrial products and batches, other departments such as customer service can benefit.

- Competitive adaptability – Automated control systems offer more flexibility in manufacturing processes and improve an organization’s competitiveness within tumultuous industrial markets.

Types of Industrial Control Systems

Industrial control systems are organized into several classes by reference to their control action’s relative complexity of the overall functions of the ICS.

Programmable Logic Controllers (PLC)

Human Machine Interface (HMI)

Distributed Control System (DCS)

Data Collection System (DCS)

Industrial Automation & Control Systems (IACS)

Intelligent Electronic Devices (IED)

Programmable Automation Systems (PAS)

Programmable Automation Controllers (PAC)

Remote Terminal Units (RTU)

Supervisory Control and Data Acquisition (SCADA)

Contact us today to see how we can help your firm through the process of designing and implementing an automated control system.

Building the future of manufacturing, together

World-class Automation