INNOVATION THROUGH AUTOMATION

Easy-Arc Cobot Welding Cart

- Home

- Industrial Automation Capabilities

- Robotic Welding Systems

- Easy-Arc Cobot Welding Cart

Easy-Arc Partners

EASYARC Welding Products

SIMPLIFY WELDING WITH AUTOMATION

The EasyArc™ welding cart is a plug-and-play collaborative welding solution that combines ABB’s GoFaTM robot with Fronius® welding technology. Designed to complement skilled welders, this cart-based system makes it simple for any shop to automate welding tasks – without fences or complex programming.

Whether you’re entering automation for the first time or expanding your welding capabilities, EasyArc is built to get you up and running fast with consistent, high-quality results.

STANDARD SYSTEM SPECS

EasyArc Cart

- Powder-coated steel frame for durability & mobility

- Integrated wire spool holder

- Swing-arm mount for FlexPendant

- Houses both controller and welder in a compact layout

- Locking casters for easy repositioning on the shop floor

- Requires only one 480V 3-phase power drop

- Expandable control for future accessories or welding upgrades

- 1-year warranty included

ABB GoFa™ CRB 15000 Cobot

- Safe, rounded design with no pinch or trap points

- Safety certified to Category 3, PL d

- Up to 2.2 m/s TCP speed—faster than others in its class

- Integrated torque sensors for precise, safe motion control

- 1050mm reach—12% longer than comparable 5kg cobots

- Powered by ABB’s OmniCore controller for energy-efficient,

high-performance motion (up to 20% energy savings) - Optional upgrade to Long Arm Cobot with 10kg payload and

1.62m reach for larger parts and extended workspaces

Fronius TPS 320i Standard Welding Package

- 320A push system, water-cooled MIG welding package

- Innovative, user-friendly touch display

- Easily adaptable to individual welding needs & parameters

- Includes standard Fronius weld package for versatile applications

- Upgrade to 400A or 500A MIG welding capacity for

heavy-duty applications

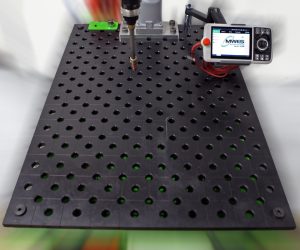

Bluco Modular Tabletop

- 1000mm x 1400mm workspace

- Precision modular fixturing system designed for robotic welding

- Achieves ±0.005” repeatability when paired with EasyArc cobot welding solutions

- Ideal for high-mix or precision applications requiring consistent setups

MWES EasyArc Software

- Intuitive interface for fast part teaching and production setup

- No advanced programming skills required—ideal for all operator levels

AVAILABLE WELDING PACKAGE UPGRADES

| EasyArc Start – On-Site Support | Includes three days of on-site setup, training, and programming support from an MWES automation technician to ensure a smooth system launch. |

| CMT Aluminum Push / Pull MIG Package |

Delivers enhanced aluminum welding performance with a torch neck pull feeder, buffer hose package, and mounting bracket—paired with advanced Fronius Cold Metal Transfer (CMT) technology for superior wire feed control, reduced spatter, and improved weld quality. |

| Collaborative Robot Torch Cleaner | Automatically maintains the welding torch with a mounted reamer, anti-spatter spray, and wire clipper to improve uptime and weld consistency. |

| Fume Extraction | Offers over-the-torch source capture for MIG systems and a re-positionable nozzle for TIG/laser setups, all integrated with a Robovent unit. |

| Single Axis Positioner | Enables precise collaborative welding of pipe and flanges with servo-controlled rotation, an 8-inch chuck, and integrated safety features for vertical, 45°, or 90° horizontal mounting positions based on your part needs. |

| Two-Axis Skyhook Weld Positioner | Servo-driven positioner enables collaborative robot control of part orientation during welding for improved precision and repeatability. |

| Dual Station Configuration | An additional Bluco modular table can be mounted to make a 2-station system. |

| Dual Wire Feeder | Allows for two different welding operations to be performed without costly change outs. |