Laser Marking & Etching

- Home

- Industrial Automation Capabilities

- Assembly Automation

- Laser Marking & Etching

Protect Your IP by laser marking your products with automation

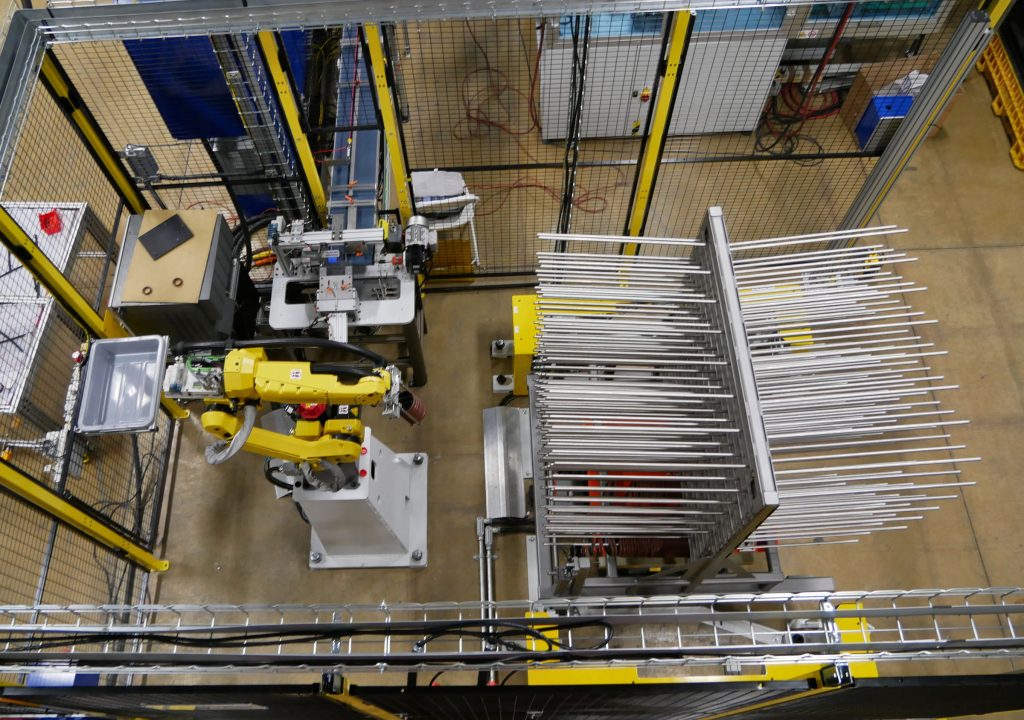

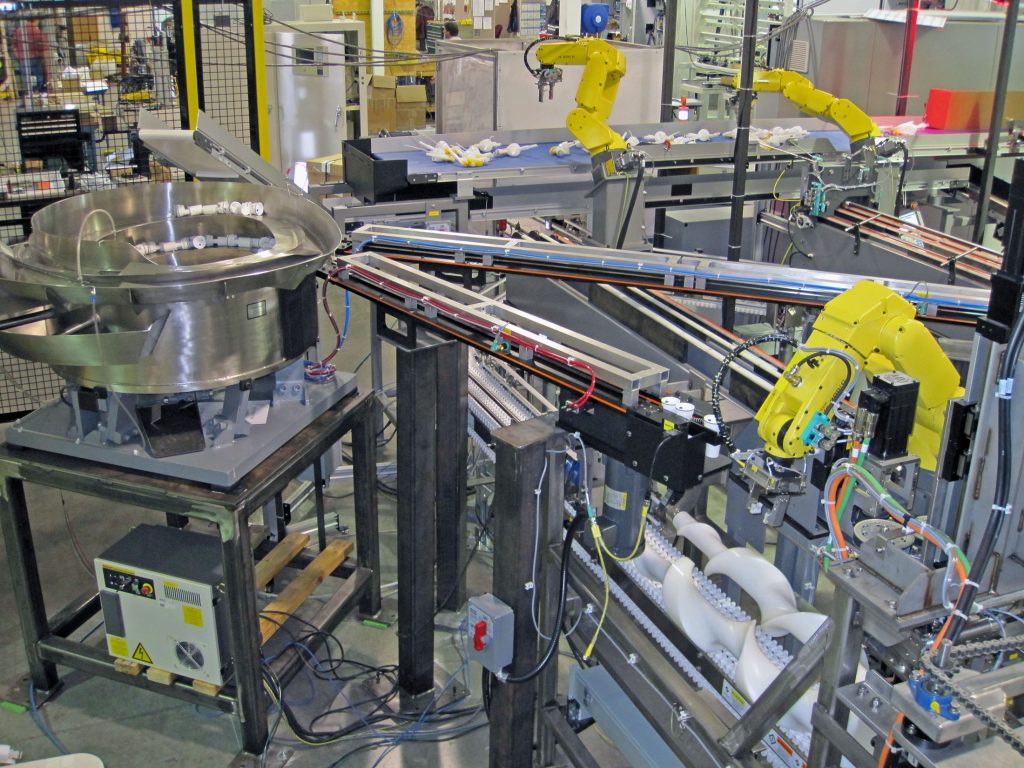

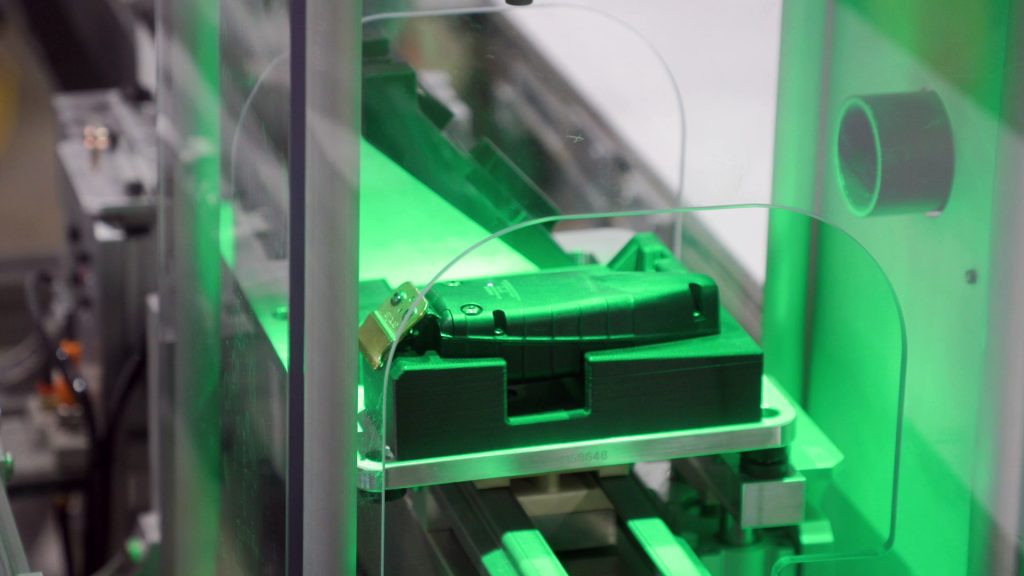

Midwest Engineered Systems integrates automated laser marking (engraving, discoloration, etching, annealing and carbon migration) systems optimized for fast and efficient output. Custom laser marking systems are built to any specific marking needs. Automated laser marking systems have the potential to maximize speed, output and accuracy, particularly for challenging marking operations. Automated laser marking can effectively mark a multitude of material surfaces such as steel, titanium, stainless steel, copper, aluminum, glass, plastic, wood, ceramic, cardboard and paper.

This noiseless process can work at very high speeds and is affected by fewer heat ranges than processes that directly contact the material. In using this process, the laser’s speed and energy level are highly adjustable, meaning the laser can be implemented within many processing ranges and levels. The result is a permanent high-contrast mark. Automating laser marking incorporates robotics and programming, applying advanced technology to the marking process of many manufacturing products. Laser marking is commonly used in many industries, including aerospace, automotive, consumer electronics, semiconductors, E-Mobility, battery manufacturing, medical equipment and pharmaceutical containers.

There are many advantages that a manufacturing line can utilize when integrating automated laser marking processes into their production systems. The following are among the most notable advantages:

- Production Rates – Laser marking and automation reduce equipment downtime and allow factories to run lights-out operations. It also virtually eliminates mistakes in marking that would inevitably occur with manual marking processes. All of these factors contribute to higher production rates.

- Energy Efficiency – Laser marking is a clean process that does not rely on consumables, unlike chemical or inkjet etching which uses chemicals and inks to create its markings. Laser marks are permanent and do not have to be reapplied or cleaned up afterward, as would be the case when operating printers long enough.

- Non-Contact Etching – Automated laser marking interacts with materials cleanly and efficiently, practically eliminating the chance of contamination. Laser marking essentially has little risk of material penetration.

- Combating Counterfeiting – Counterfeiting is a global issue affecting many industries, particularly the pharmaceutical industry. Additionally, marking on pharmaceutical bottles must be tamper-proof, very easy to read, cannot affect the medical product and must be environmentally friendly. The optimal solution for counterfeiting and these other concerns is laser internal engraving.

Building the future of manufacturing, together

World-class Automation