Blog & News

Check out the latest from MWES

Categories

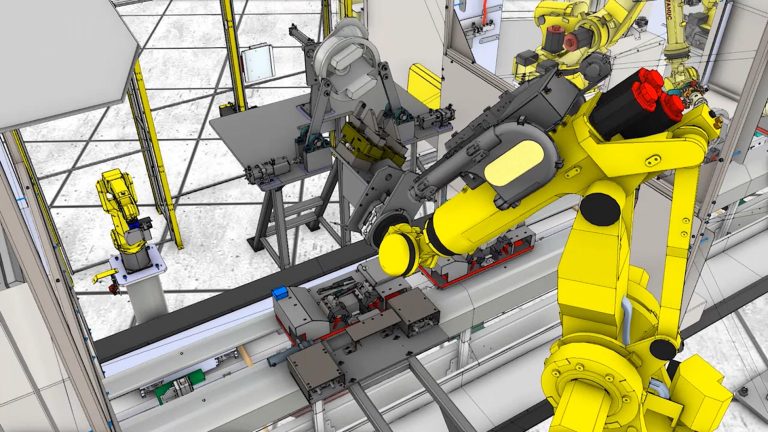

Embracing Automation: Mitigating Risks in the Transition from a Manual to a Robotic Workforce

Global manufacturing stands on the brink of a transformative leap – the shift from a volatile manual labor workforce to a fully automated robotic process. This transition brings about increased efficiency, productivity and long-term cost savings. However, it does carry with it a host of risks that need to be

Get a Federal Tax Break on Automation Equipment with Section 179

If you are the owner of a small to medium-sized business looking for ways to reduce your tax liability and increase your productivity, you may want to consider investing in industrial robotic automation. Robotic automation in itself can help your business save time, money, and resources over time while improving

The Return on Your Investment: Manual vs. Robotic Automation

Why would you want to use robotic automation over manual labor? Simply put robotic automation offers many benefits for your business, such as increased productivity, efficiency, quality, safety and throughput. All of these add up to substantial savings over the long term for any business that deals in manufacturing, assembly,

A Checklist for Automation RFQ Information Whitepaper

Putting together an RFQ or even earnestly exploring automation, is a job unto itself. It can be difficult to know what an automation integrator may need to start the process. Providing the right information helps develop a quote package.

Consolidating production processes with automation

Moving toward automating production facilities that have a few or more lines can be an overwhelming prospect. Each line may need upgrades. Judging which should receive more of the budget is a task that may not have a clear cut solution.

Proof of Principle Testing Takes the ROI guesswork out of automation

Looking into automation for a particular production process? Determining if automation is the correct way to go may be a rather murky prospect, especially if there’s no off-the-shelf system to do it. There’s a way to prove out whether automating that process would have the ROI that the firm needs without having to build the entire system.

Knowing What to Automate First

When you oversee an entire manufacturing system, there’s a forest of opportunities to automate. How do you pick the first process to tackle first?

Investigate automation potential with MWES’ Proof of Principle testing

For a lot of operations, the easy automation projects are essentially solved. Simple pick-place operations and general machine tending applications lead that charge with robot-in-a-box solutions. But what if you have a process that’s a lot more complex?